Alexia

NAXJA Forum User

- Location

- Huntsville, AL

Hey - I am bringing this build thread over to  to share the technical rebuild information into restoring a Jeep. I originally started this over on JPF.

to share the technical rebuild information into restoring a Jeep. I originally started this over on JPF.

Many of us that have drove for a long time know the agony of wrecking your favorite vehicle is painful. I previously had a Cherokee that I wrecked and was repaired by a shop. This is one of those stories, but in this story I will be doing the repairs. I responded to a Craigslist advertisement for a cheap 1996 Jeep Cherokee Classic. It was very cheap, a mechanic special for any one with the skills to fix it. A deer was upset with a creature more beautiful than it being in its territory and took a suicide bombing run into the grill. The Jeep survived and continued to run strong with need of immediate surgery. I promised the previous owner after taking it into my care I would fix it to keep a Cherokee on the road. Considering that many were lost to Cash for Clunkers, this is a worthy clause.

I will include some step by step of what you should do during the rebuild of your smashed front end.

TO DO

Strip Interior.(Reeks of smoke.)

Remove crappy tint.

Remove rat nest of light wiring including roof lights.

Redo head liner.

Paint interior plastic trim black.

Line-X Interior

Straighten bumper brackets

ENGINE PARTS

Steering pump with out reservoir

Air box

Fan clutch

Fan(Possibly)

AC Condenser

Radiator

Radiator support

Radiator isolators(Manufacturer 52002585, Quadratec 51219.000)

Electric Fan

Mechanical Fan Shroud

EXTERIOR PARTS

Header panel

Grill insert

Head light bezels

Head lights

Head light buckets/brackets

Marker lights, front and side

Light wiring harness connectors

Left Fender

Hood

Right Fender(Only if doing 1997-2001 swap.)

Front Bumper

INTERIOR PARTS

Switch plates next to steering column

I did not pay the price listed on the glass! Yes, this is a 2WD drive Jeep and may become a candidate for Jeepspeed. Also, the real paint color is black. The flat cheap spray paint poop/olive color has become contaminated with dirt that will not come out in a wash.

The minor, the interior. Those are exposed hooked up wires!

Front End

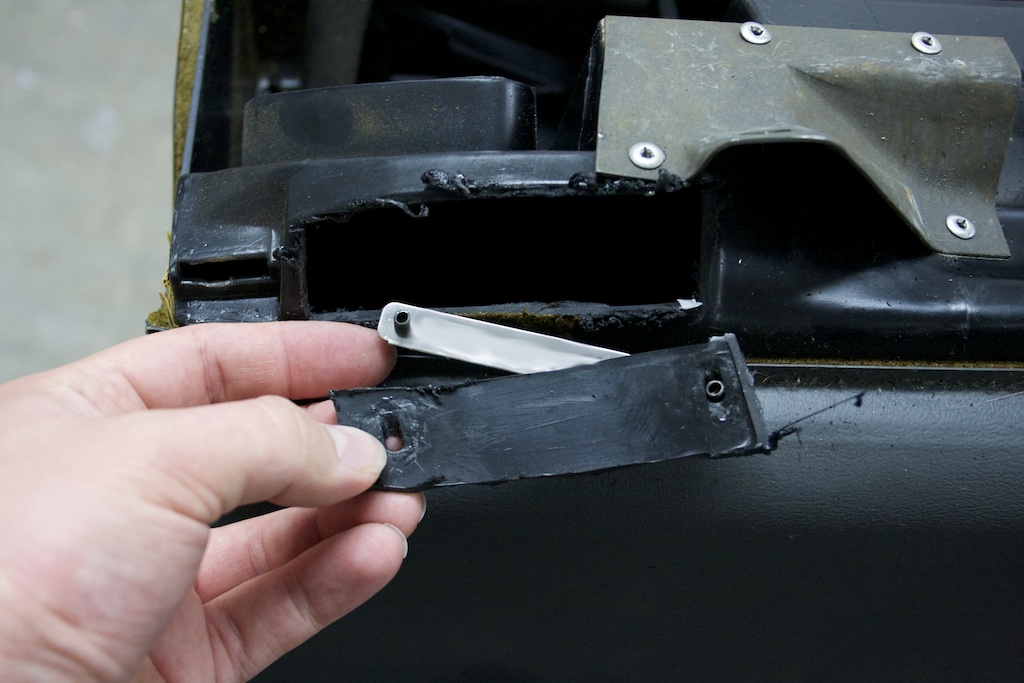

Radiator filler neck destroyed the air box. The radiator support looks salvageable, but the inner fender needs repaired.

The belt is actually straight. The steering pump pulley is bent in a comically wobbly fashion.

I will get a better picture of the pulley and fan dents on the radiator once I get it pulled apart.

to share the technical rebuild information into restoring a Jeep. I originally started this over on JPF.

to share the technical rebuild information into restoring a Jeep. I originally started this over on JPF.Many of us that have drove for a long time know the agony of wrecking your favorite vehicle is painful. I previously had a Cherokee that I wrecked and was repaired by a shop. This is one of those stories, but in this story I will be doing the repairs. I responded to a Craigslist advertisement for a cheap 1996 Jeep Cherokee Classic. It was very cheap, a mechanic special for any one with the skills to fix it. A deer was upset with a creature more beautiful than it being in its territory and took a suicide bombing run into the grill. The Jeep survived and continued to run strong with need of immediate surgery. I promised the previous owner after taking it into my care I would fix it to keep a Cherokee on the road. Considering that many were lost to Cash for Clunkers, this is a worthy clause.

I will include some step by step of what you should do during the rebuild of your smashed front end.

TO DO

Strip Interior.(Reeks of smoke.)

Remove crappy tint.

Remove rat nest of light wiring including roof lights.

Redo head liner.

Paint interior plastic trim black.

Line-X Interior

Straighten bumper brackets

ENGINE PARTS

Steering pump with out reservoir

Air box

Fan clutch

Fan(Possibly)

AC Condenser

Radiator

Radiator support

Radiator isolators(Manufacturer 52002585, Quadratec 51219.000)

Electric Fan

Mechanical Fan Shroud

EXTERIOR PARTS

Header panel

Grill insert

Head light bezels

Head lights

Head light buckets/brackets

Marker lights, front and side

Light wiring harness connectors

Left Fender

Hood

Right Fender(Only if doing 1997-2001 swap.)

Front Bumper

INTERIOR PARTS

Switch plates next to steering column

I did not pay the price listed on the glass! Yes, this is a 2WD drive Jeep and may become a candidate for Jeepspeed. Also, the real paint color is black. The flat cheap spray paint poop/olive color has become contaminated with dirt that will not come out in a wash.

The minor, the interior. Those are exposed hooked up wires!

Front End

Radiator filler neck destroyed the air box. The radiator support looks salvageable, but the inner fender needs repaired.

The belt is actually straight. The steering pump pulley is bent in a comically wobbly fashion.

I will get a better picture of the pulley and fan dents on the radiator once I get it pulled apart.

Last edited: