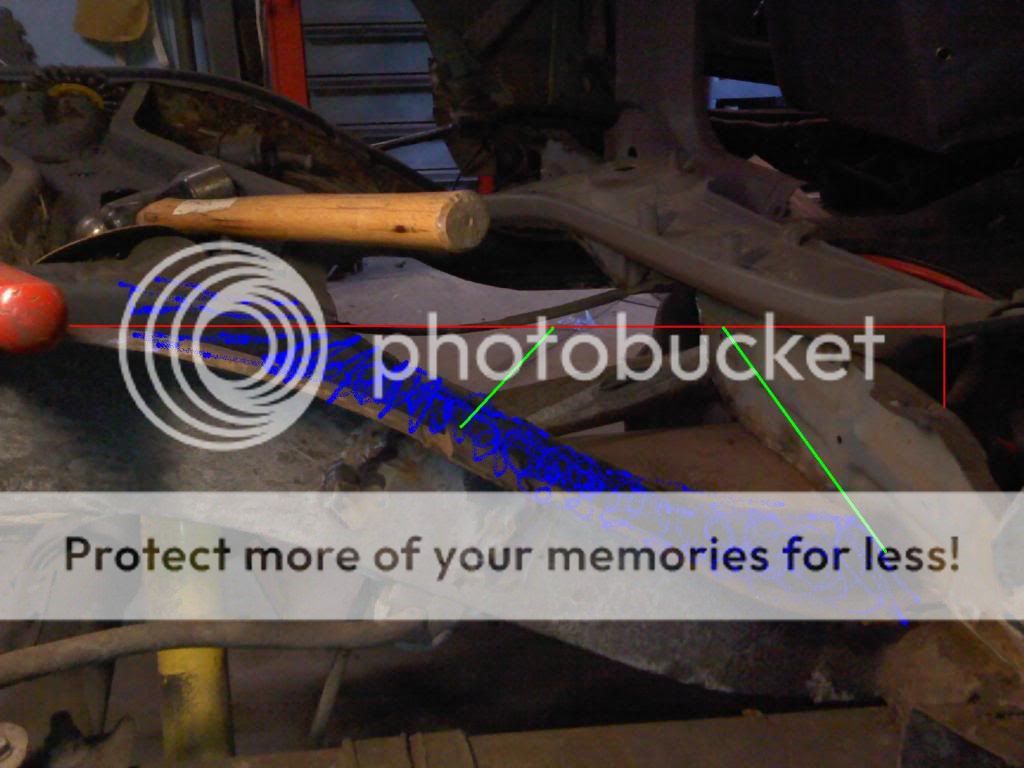

so i figured i'd drop some pictures and start a build thread here... it's going to be slow... i only have time to work on it in the winter... and being a po boy doesn't help.... so anyway here's what i'm starting with...

93 2dr 4.0 aw4 np231

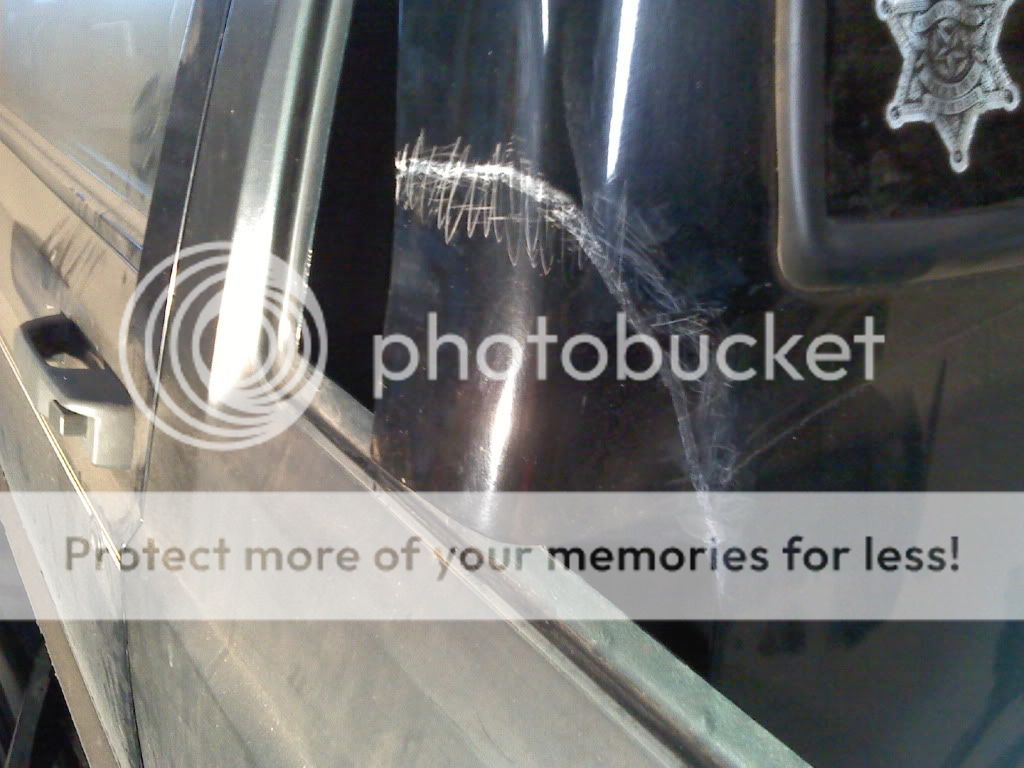

when i brought it home a few months ago... yeah the shitty s10 visor is long gone...

on to the plans...

1. fix rust

2. cut gratuitus amounts of sheet metal

3. make some bumpers

4. make some mini boatsides

5. chop the top

6. add full cage

7. add 231/300 doubler

8. full width hp44/9in combo

9. lift

10. run 37's

so with all the trimming, i'm hoping to only need about 4in of lift to clear the 37's and still be able to have about 5in of up travel... i won't know for sure until i get it all cut and sitting back on level ground to take some measurements...

93 2dr 4.0 aw4 np231

when i brought it home a few months ago... yeah the shitty s10 visor is long gone...

on to the plans...

1. fix rust

2. cut gratuitus amounts of sheet metal

3. make some bumpers

4. make some mini boatsides

5. chop the top

6. add full cage

7. add 231/300 doubler

8. full width hp44/9in combo

9. lift

10. run 37's

so with all the trimming, i'm hoping to only need about 4in of lift to clear the 37's and still be able to have about 5in of up travel... i won't know for sure until i get it all cut and sitting back on level ground to take some measurements...