- Location

- San Diego

yes but with the old ones you have to find a way to seal the transfer case, which would be the hardest part.

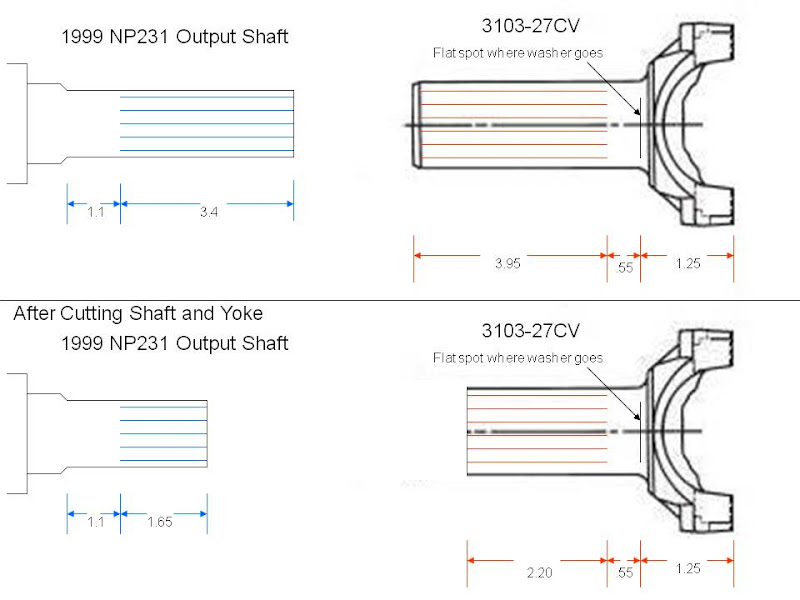

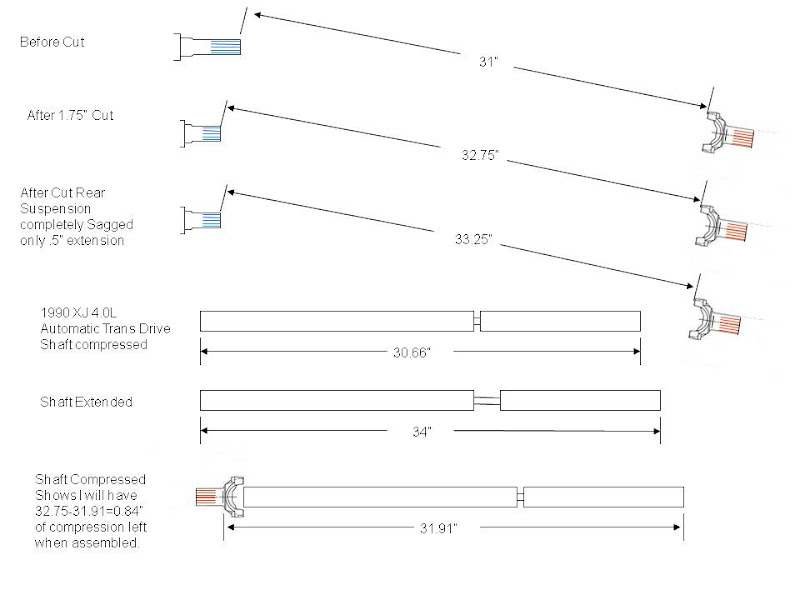

I have a 1999 XJ with a 4.0L engine, automatic, NP231 transfer case, Chrysler 8.25 rear axle, and a new 3 inch budget boost. I had vibes so I tried a transfer case drop. It didn’t work, so I decided I needed a SYE. I started looking at how to do it cheap. I found lots of discussion about home brew SYEs using the 3103-27CV yoke and front drive shafts out of XJs, but I couldn’t find guidance where to cut the yoke and transfer case output shaft. I hope this post helps others.

the shaft is case hardened and you will not be able to drill it by hand without cutting some of the end off.

And the farther the yoke is from the main TC output bearing the more stress you will put on it, which will make it fail faster under higher stress. It would be a much better idea to cut the output shaft as far back as possible and get your driveshaft extended to the correct length.