travisk

NAXJA Forum User

- Location

- Fullerton, CA

I'm about to start this swap so I figured I'd let you watch this mess unfold. If you see me about to do something stupid, please let me know.

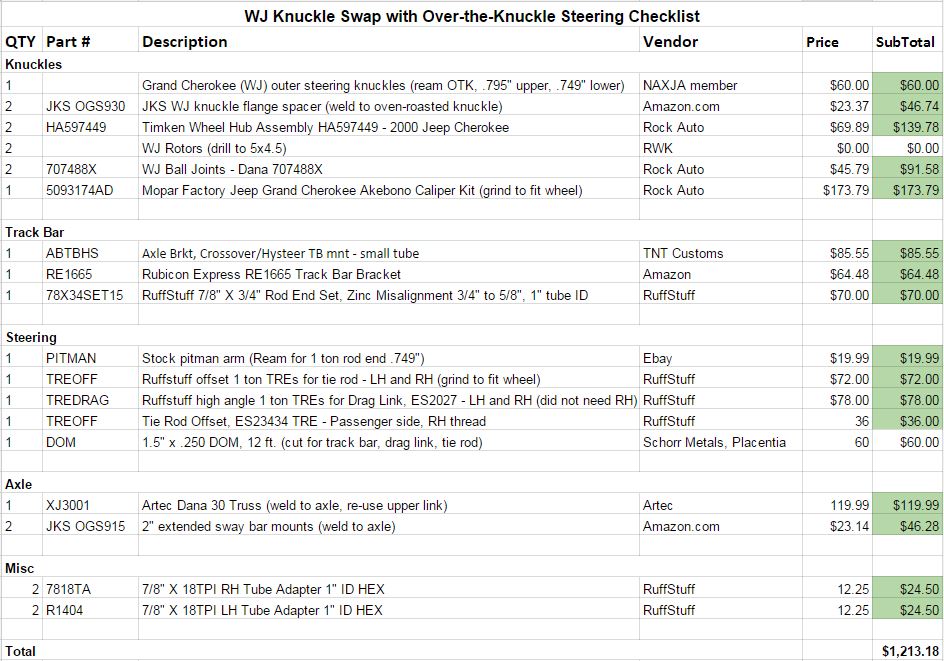

Here are the parts that I've acquired over the last few months.

My parts list (Google Doc)

Started by baking the knuckles in the oven at 500 degrees for two hours, then ran them over to my buddy's shop so he could weld on the flanges. They were cooled in a bucket of sand for several hours.

This is all I have so far. Once I pull the axle off I won't be able to drive my jeep until it's all done, so I'm hesitating.

Here are the parts that I've acquired over the last few months.

My parts list (Google Doc)

Started by baking the knuckles in the oven at 500 degrees for two hours, then ran them over to my buddy's shop so he could weld on the flanges. They were cooled in a bucket of sand for several hours.

This is all I have so far. Once I pull the axle off I won't be able to drive my jeep until it's all done, so I'm hesitating.