Mike1331

NAXJA Forum User

- Location

- Folsom, CA

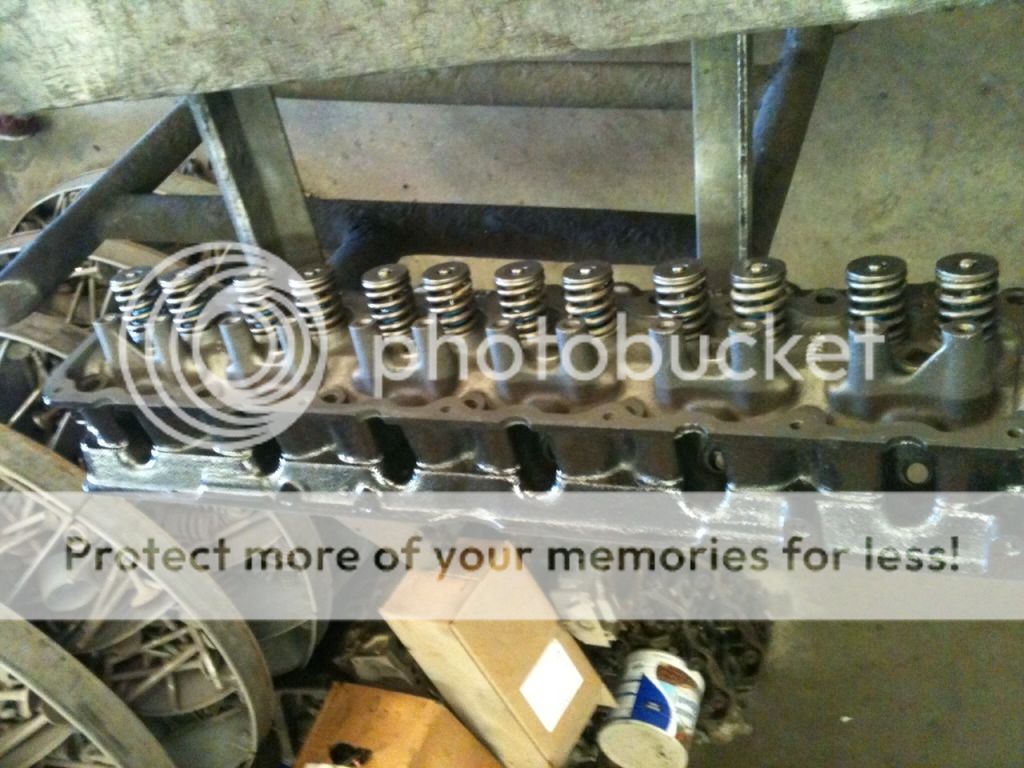

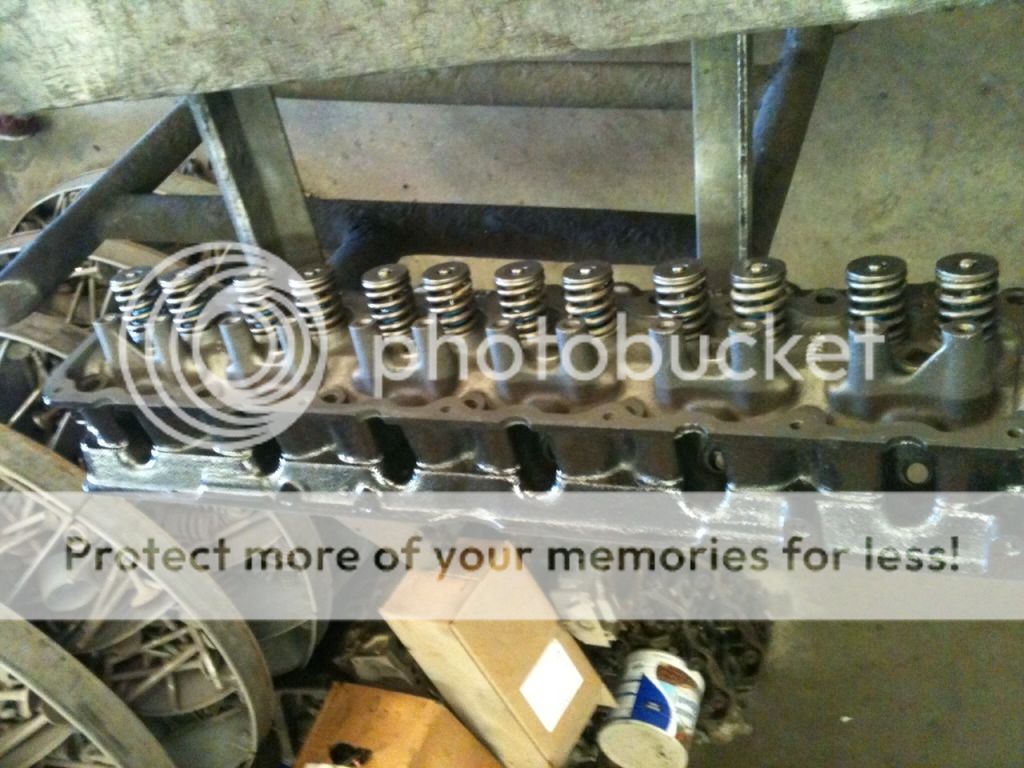

I just got my renix head rebuilt. It had 4 cracks, was warped and had one pitted valve from water intrusion. Sucker was tired. She's all fixed and now i'm wondering what head gasket to get since i have a 98 block.

And my head was warped so he had to resurface it, should i get a different thickness gasket than standard?

Second item: Does anybody know what to torque the crank girdle nuts to? It was only an item they did i think with the obdII blocks and my book was written before that. i have to take it off to take off the rear main bearing cap to replace the rear main seal but it doesn't list a crank girdle spec in my book.

super happy with head guy.

$200 out the door for valve job, resurface, seals, one new valve, new valve retainers, and to repair 4 cracks.

And my head was warped so he had to resurface it, should i get a different thickness gasket than standard?

Second item: Does anybody know what to torque the crank girdle nuts to? It was only an item they did i think with the obdII blocks and my book was written before that. i have to take it off to take off the rear main bearing cap to replace the rear main seal but it doesn't list a crank girdle spec in my book.

super happy with head guy.

$200 out the door for valve job, resurface, seals, one new valve, new valve retainers, and to repair 4 cracks.

Last edited: