Spent much of the summer working on yard projects, but have squeezed in some fab time on the Jeep, so I guess it's time to update the thread.

Universal Swaybar installation

I ordered the Currie 35.75" wide kit which requires you to fab your own mounting brackets. I had some custom brackets cut for me by Ben Hank's Racing on their plasma table. w

ww.benhanksracing.com The brackets are 4" w and 3.25" h, which I then welded to the base plate, made from 1/4" t x 2" w strap.

I did some test fitting on the Jeep and when everything was lined up properly, I welded the brackets to the supplied crosstube.

I also had the folks at BHR bend the arms for clearance and to provide proper alignment with my endlink axle brackets. Bending the arms also shortens their overall length (17" is the shortest arm available, which is still too long for the XJ, requiring you to cut off an adjustment hole or two) which allowed me to retain 4 of the original 5 endlink mounting holes for more tuning options. Von at BHR also suggested adding a gusset to the bend, as they've seen some lateral twisting occur on the bent arms they've installed on their comp buggies when not gusseted......simple fix, so why not? I used some 1/8" t strap I had laying around for these gussets.

I welded the crossbar assembly to my Jeep, then on to primer and finish paint on everything.

The endlinks tubing comes pre-threaded with left and right-hand threads for easy adjustment, but are a cut-to-fit design. Since the tubes were only threaded about 2" deep, my solution was to take measurements for overall endlink length, then chop the middle out of the tubes and weld the pieces back together, netting the proper endlink length. Worked perfectly.

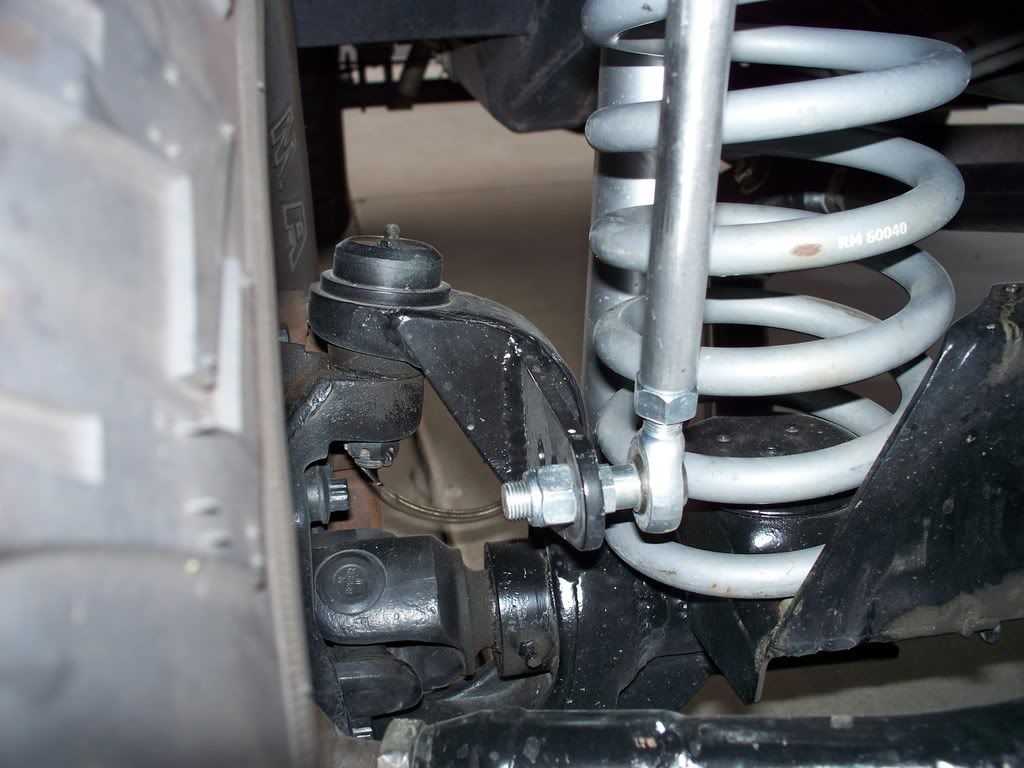

Installed photos:

Gusset view

Endlink Axle bracket supplied with kit, which I attached to my gusseted knuckle.