- Location

- Lafayette, IN

Ok. Got my Aussie for my D44, so it's time to tear it apart and install. Had to remove the carrier because the ring gear is too thick to get the cross pin out otherwise. No problem.

Bought a set of punches to get the roll pin (spring pin, tension pin, whatever you call it - holds the cross pin in place). Used a punch that was slightly too small. I was punching it from the driver's side to the passenger's side, until the punch bottomed out (the thick part at the top of it) and then broke off and not it is stuck inside roll pin which is stuck inside carrier.

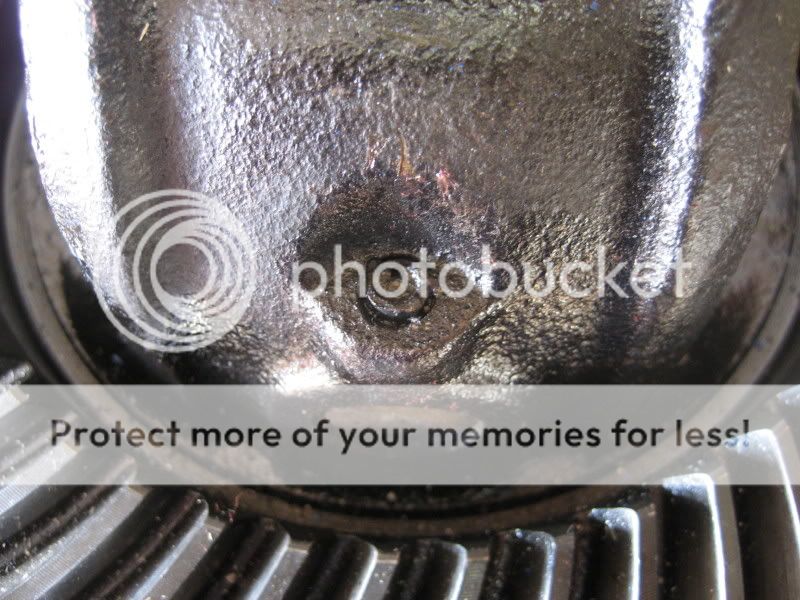

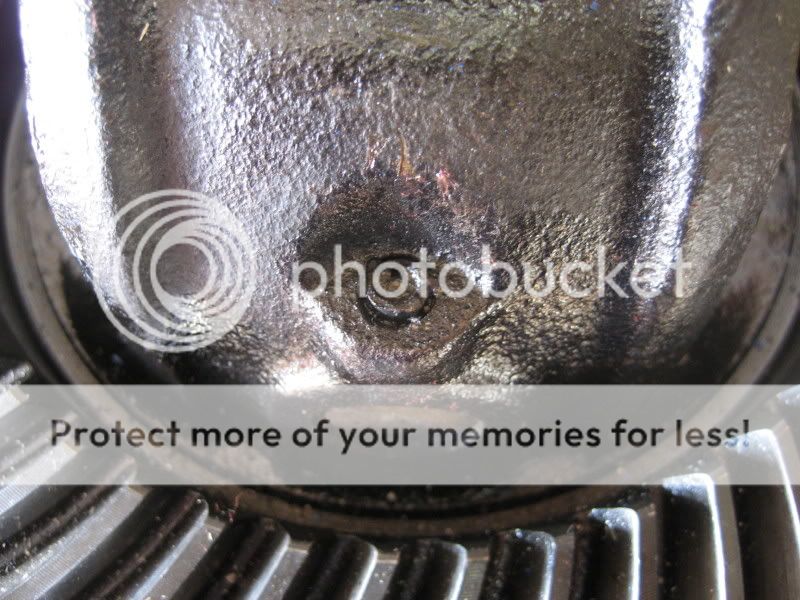

What you are looking at here is the roll pin, broke off on the passenger side of the carrier, with the punch stuck in it.

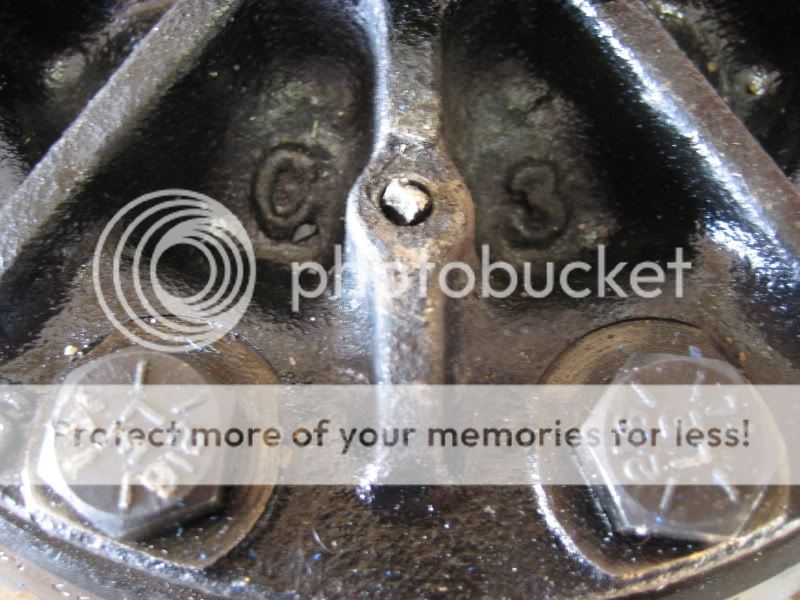

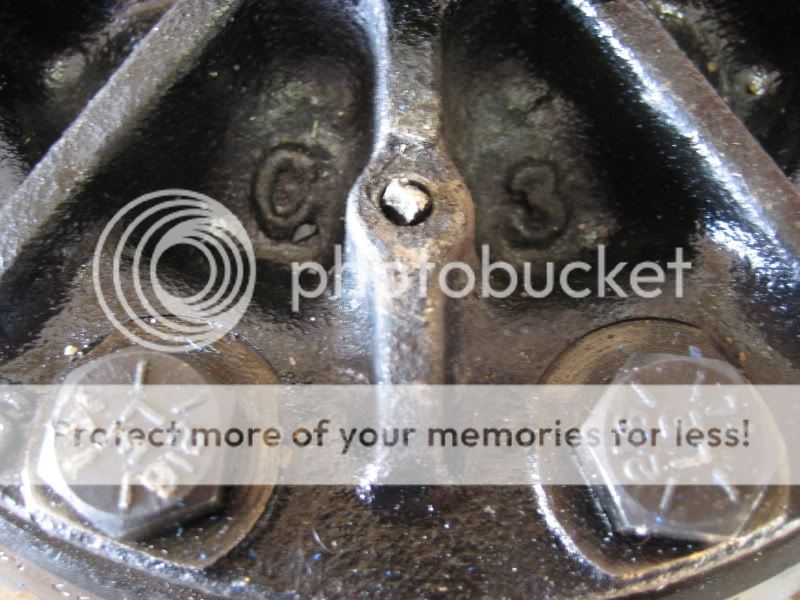

And here is the other side, where I tried to use a drill bit (closest thing I had to a punch) to get it out after the punch broke. It is more or less stuck in there.

What can I do? Starting to look like EDM might be my only option. Otherwise I have to buy a new empty carrier and move my gears over, then pay to get them re-installed and set up. Just wondering what ideas anyone else has. Have tried torching the carrier to heat it up and pounding it out, no success so far but I will probably keep trying that.

Bought a set of punches to get the roll pin (spring pin, tension pin, whatever you call it - holds the cross pin in place). Used a punch that was slightly too small. I was punching it from the driver's side to the passenger's side, until the punch bottomed out (the thick part at the top of it) and then broke off and not it is stuck inside roll pin which is stuck inside carrier.

What you are looking at here is the roll pin, broke off on the passenger side of the carrier, with the punch stuck in it.

And here is the other side, where I tried to use a drill bit (closest thing I had to a punch) to get it out after the punch broke. It is more or less stuck in there.

What can I do? Starting to look like EDM might be my only option. Otherwise I have to buy a new empty carrier and move my gears over, then pay to get them re-installed and set up. Just wondering what ideas anyone else has. Have tried torching the carrier to heat it up and pounding it out, no success so far but I will probably keep trying that.