LEDs!! These were purchased at a local gadget shop that cares stuff from old computers to LEDs or about any shape and size. The ones I ended up getting, under advice from my roommate who going to college to be a electrical technician, 2 12V LEDs. Getting LEDs that out of the box work at 12v makes this install almost to easy since there is no dealing wih anything other than running the wires and finding a good spot to mount it.

After some debate and having my center console removed to find good ground spots I settled on the faceplate right next to the cig lighter since I just needed enough room to make 2 small holes. and to my surprise when I turned it around it was the perfect space for it. I grabbed my trusty dremel and made the 2 holes and removed all the plastic on the inside that would interfere with the leds and wires, then just made a notch on the top for the wire to run through and I was in business.

I ended up purchasing from the same gadget store x2 lengths of 12ft cord of wire for the leds and ended up just 4in short(that's what she said) I ran the wire for the flexalite fan on the left side while I ran the wire for the A/C fan on the right. I used the same splicer that I used on the fuel pump relay/control box. Just right off the positive from the fan so there is no mistaking if the fan is running or not

Here is a pic of the LED with the wires soldered.

Here I have the LED sitting nice and comfy in it's new home. I used a small hot glue gun since I did not want to have to deal with super glue. I learned my lesson from watching American Pie. Also hot glue would allow me to remove the LEDs should one stop working or not work at all. I put a dab on the plastic cover then pressed on the led then after about 30secs of holding it a liberally applied hot glue to the op to make sure it wasn't going to work itself free later on.

With both LEDs installed I then applied a small dab of hot glue to the front of the leds. Sortof as a protective coat and to diffuse the light a bit. That's just sexy!

Also in the background you can see the bolt that I used for the ground for the leds. Was really close and a good solid metal metal contact point

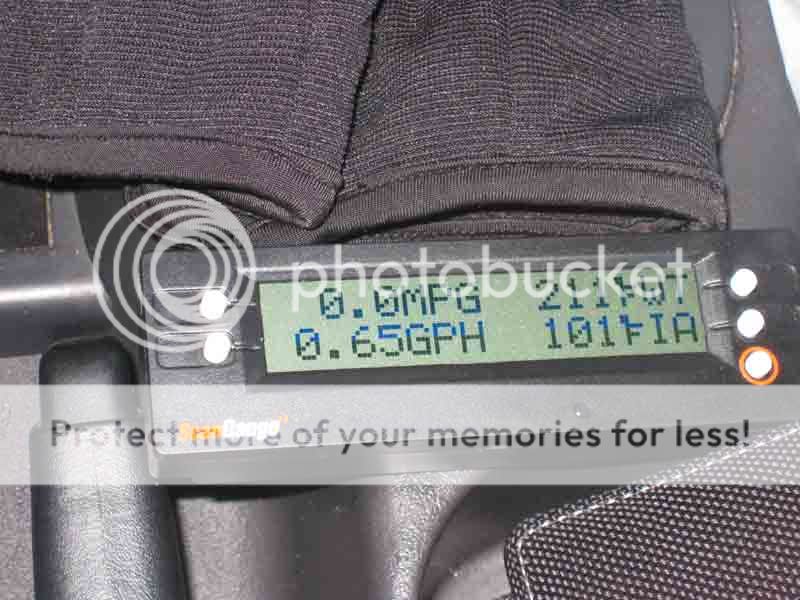

Here is the finished product taken while driving insanely fast in the interstate in the snow.....really, while in park waiting for the engine to heat up it finally cut on so I could take a picture.

I'll point out that the top led is the flexalite fan and the bottom fan is for the A/C overheat fan. The bottom one does not cut on and is probably due to when the solder was put on the led it didn't take well. Just a quick fix once I get my buddy to redo it. I'm not that good with a hot pokey thing X_o. That about does it. I've done a few other things to my Jeep so maybe I should make a thread just for my XJ like others here just to post updates on lil things here and there that I do to her. Well hope this helps you guys cuz I know it gave me the confidence now to want to working the electrical side of my Jeep instead of only the mechanical.

~FastDemise~