emr1101

NAXJA Forum User

- Location

- Raleigh, NC

Okay, so I am pretty much fed up with the dead spot in my steering from my JCR 1 ton. It is a beefy kit, yes, and I am sure it can hold its own off road, but onroad manners are dangerous. The dead spot is an inherent problem and I am trying to think of a way to fix it. I discussed this with a a few people all of them said they can't see why it wouldn't work, so tell me if this makes sense..

Okay, so the problem of the dead spot is caused by the tie rod rolling, well why does it roll? It rolls so that the drag link is able to stay connected to it without binding, thus the axle-end TRE of the drag link is attatched on the side of the tie rod.

Soooooo heres my idea, what about making the TREs FIXED to the knuckles? The knuckles relative position to each do not change, so if you can keep the Tie rod from rolling then there will be no dead spot. The problem with this is then the steering will bind since the drag link's axle-end TRE is attatched to the SIDE of the tie rod... so howabout move it to the top? Would this work? IF (big if) the TRE is flexible enough and has a big enough threshhold for lateral rotation then this should work.

So my idea is take this part (unless there is a part like this already in production)

And turn it so that the hole is side ways, then cut off the TRE tip, and cut out the tab inside that would otherwise be pressed into the knuckle, and weld this piece to the end of hte unit. you would lose like .5-1", but there is plenty of extra thredding.

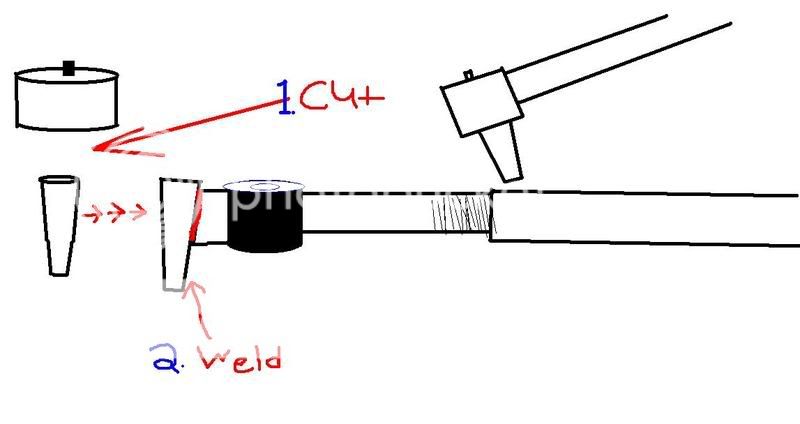

Here is my idea...

Three steps actually, cut off the TRE "joint", drill/tap/saw whatever you have to do to get the pole thing out, and weld it onto the rest of the TRE, this way A) the tie rod will be still, and B) the drag link will attatch on the top.

Obviously this could be done a lot better if i could manufacture it myself, this is just my simple way to do it. I see 2 problems, one is welding the piece on, it had better be a good damn weld for safety reasons, maybe also tac it to the knuckle? I dont know much about welding. Also, offroad under extreme flex not sure how the drag links TRE would do, again i dont know the threshold.

Okay, so the problem of the dead spot is caused by the tie rod rolling, well why does it roll? It rolls so that the drag link is able to stay connected to it without binding, thus the axle-end TRE of the drag link is attatched on the side of the tie rod.

Soooooo heres my idea, what about making the TREs FIXED to the knuckles? The knuckles relative position to each do not change, so if you can keep the Tie rod from rolling then there will be no dead spot. The problem with this is then the steering will bind since the drag link's axle-end TRE is attatched to the SIDE of the tie rod... so howabout move it to the top? Would this work? IF (big if) the TRE is flexible enough and has a big enough threshhold for lateral rotation then this should work.

So my idea is take this part (unless there is a part like this already in production)

And turn it so that the hole is side ways, then cut off the TRE tip, and cut out the tab inside that would otherwise be pressed into the knuckle, and weld this piece to the end of hte unit. you would lose like .5-1", but there is plenty of extra thredding.

Here is my idea...

Three steps actually, cut off the TRE "joint", drill/tap/saw whatever you have to do to get the pole thing out, and weld it onto the rest of the TRE, this way A) the tie rod will be still, and B) the drag link will attatch on the top.

Obviously this could be done a lot better if i could manufacture it myself, this is just my simple way to do it. I see 2 problems, one is welding the piece on, it had better be a good damn weld for safety reasons, maybe also tac it to the knuckle? I dont know much about welding. Also, offroad under extreme flex not sure how the drag links TRE would do, again i dont know the threshold.