RacecaR

NAXJA Forum User

- Location

- Arlington Heights, IL

I used a dremmel to expand the air vent hole. I have one + lead from a 12V source. Another + lead wired in parallel with the dash light circuit...I don't remember exactly which # fuse the dash light circuit is, just consult your owners manual. One ground and one CAT-5 cable to the fuse box.

Dropped in

The switches and switch holder are from otrattw.com. Jim was a super cool guy to work with and I'd order again from him anytime. The upper light illuminates when the switches is activated. The lower slit light is illuminated when I turn on the headlights. I would have prefered to have all red switches to match the exterior color of my XJ, but the fog lights and backup lights switches were only avaliable in blue. However, the red-blue-red works because my CD deck has a blue display and the blue switches are directly below that display.

Leftovers anyone?

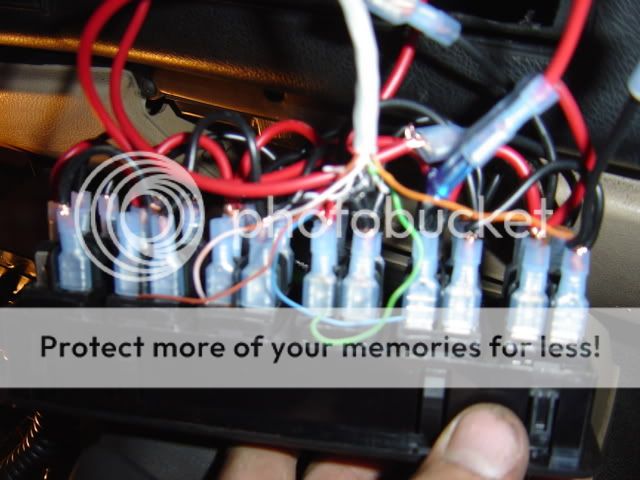

This fuse box was built in Tupperware I found in the kitchen and was inspired by FitchVA. The box is only temporary sealed with duct tape because I still need to install my fog lights and long range lights. But currently I have one relay to override the aux fan. One for the stock AC compressor converted into an OBA system. And one for a pair a fog lights I installed inside the rear bumper so the light itself is flush with bumper.

Overall, the install had no unexpected problems. I recommend buying female terminals in bulk...I used a box of 100. Also, the switch panel may look a bit crooked to you, but it's just in comparison with the movable plastic overlay. The hole I cut is indeed horizontal and since the photographs I have adjusted the plastic trim so that it does line up with the switch panel.

:wave1:

Last edited: