DrMoab

NAXJA Forum User

- Location

- The Utah Backwater

I think I know the answer to this but I need some backup.

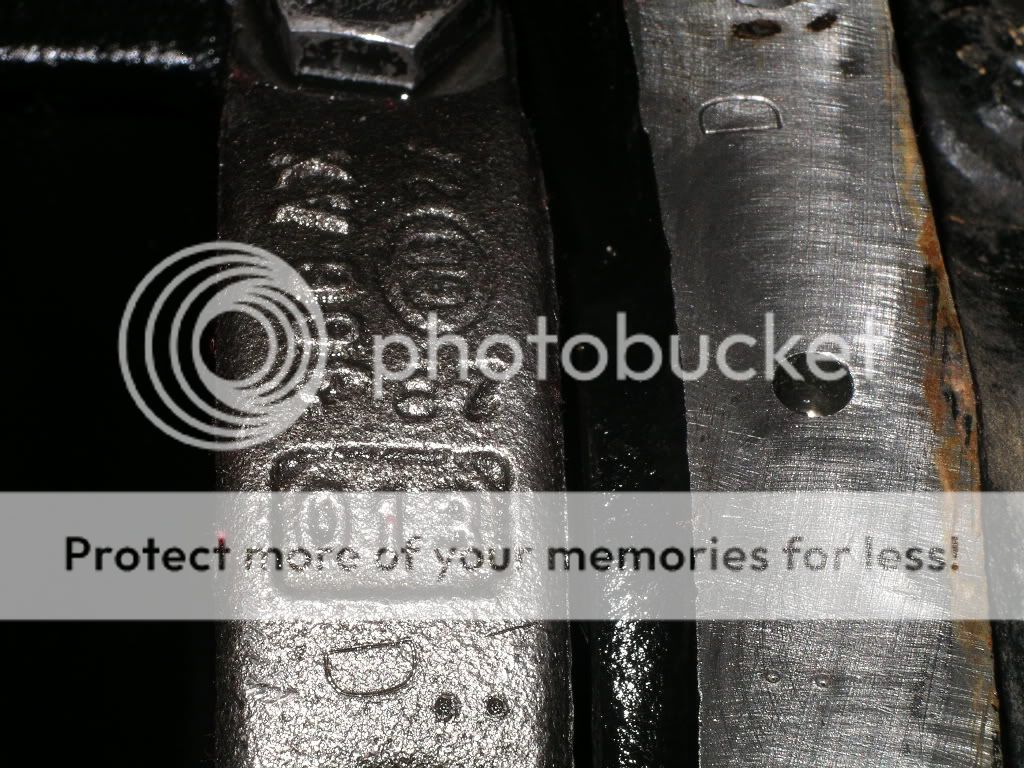

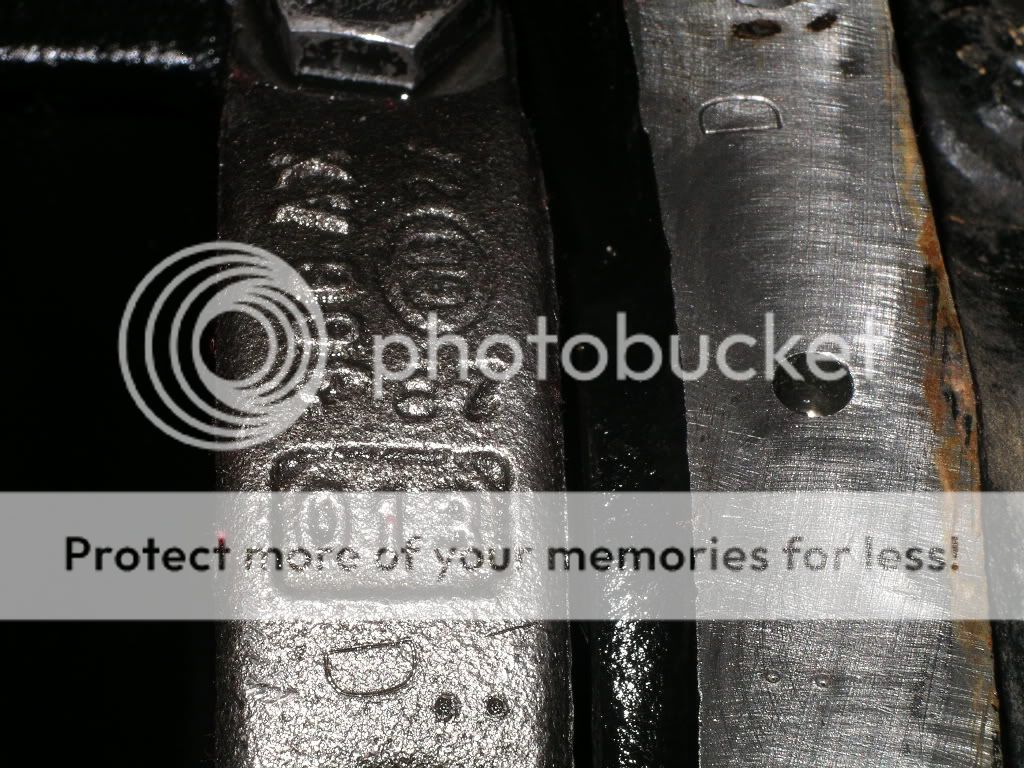

I pulled the gear set out of a D44 today and found that the little "D"s on the bearing caps were both upside down.

Here is a couple pics. I put the caps back on after I pulled the carrier out to show you how they came out.

So my question is. Should I put this together the way I think it should be? With the "D"s matched up? Or did Dana ever screw up and put this on the wrong side? (yeah yeah I know)

Also...other then to the carrier bearings which are going to be replaced along with the carrier...will this cause any damage to the case?

Thanks oh wise ones of Dana Lore.

I pulled the gear set out of a D44 today and found that the little "D"s on the bearing caps were both upside down.

Here is a couple pics. I put the caps back on after I pulled the carrier out to show you how they came out.

So my question is. Should I put this together the way I think it should be? With the "D"s matched up? Or did Dana ever screw up and put this on the wrong side? (yeah yeah I know)

Also...other then to the carrier bearings which are going to be replaced along with the carrier...will this cause any damage to the case?

Thanks oh wise ones of Dana Lore.