ricot83

NAXJA Member #1297

- Location

- newington, CT

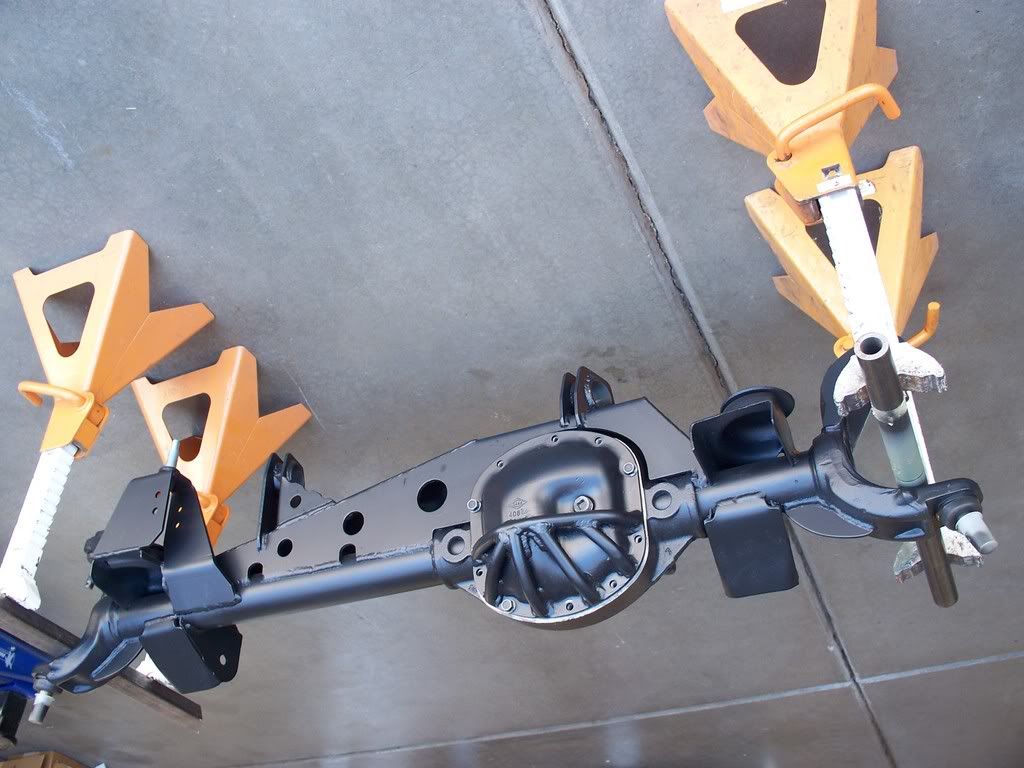

The axle:

1990 Dana 30 disconnect 4.10 gears

The plan:

-change seals so I can use the 99 axle shafts.

- Change the knuckles over from my 99 and of course brakes, hubs blah blah.

-Weld a little plate where the track bar bolt goes so I can avoid death wobble.

-Weld on control arm mount skids so I didnt pretzel them

-reinforce the welds on the lower control arm mounts as well

-Possibly change ball joints if needed.

- maybe weld the axle tubes to the housings(vacuum and diff)

- block off the vacuum housing and remove any extra shit that is there.

-maybe a small truss like rusty's I can make from scrap steel ( not sure about this one)

What else would you add to this list, within reason and my price range.......CHEAP ?

1990 Dana 30 disconnect 4.10 gears

The plan:

-change seals so I can use the 99 axle shafts.

- Change the knuckles over from my 99 and of course brakes, hubs blah blah.

-Weld a little plate where the track bar bolt goes so I can avoid death wobble.

-Weld on control arm mount skids so I didnt pretzel them

-reinforce the welds on the lower control arm mounts as well

-Possibly change ball joints if needed.

- maybe weld the axle tubes to the housings(vacuum and diff)

- block off the vacuum housing and remove any extra shit that is there.

-maybe a small truss like rusty's I can make from scrap steel ( not sure about this one)

What else would you add to this list, within reason and my price range.......CHEAP ?

Last edited: