tayman

NAXJA Forum User

- Location

- Niceville, FL

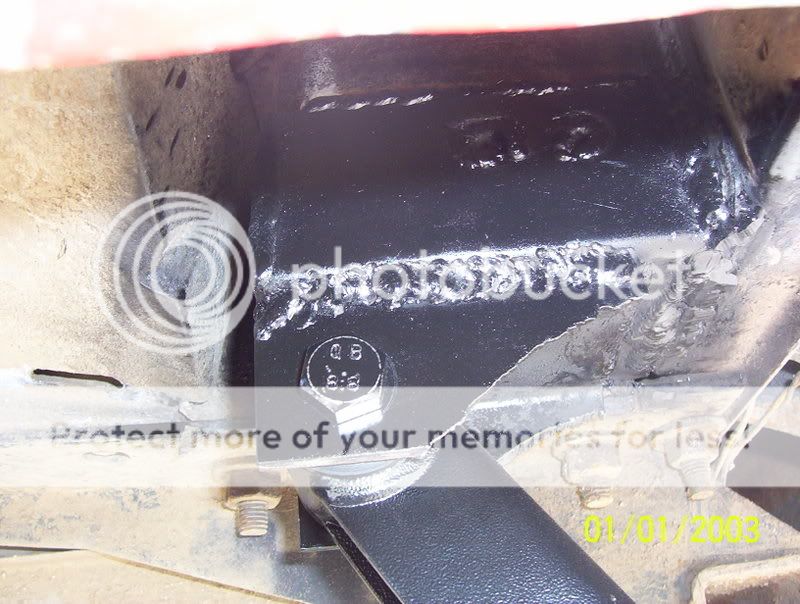

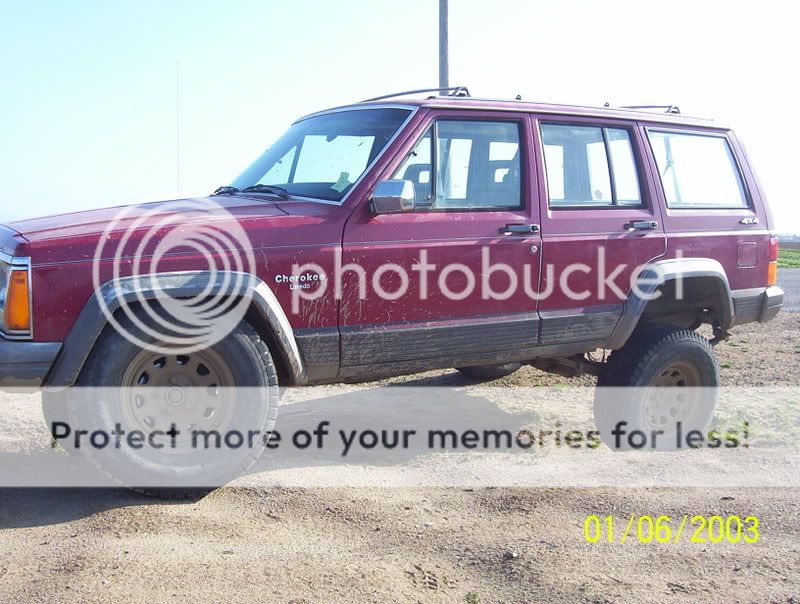

A) Ok, so I have a shitty shackle angle. It's vertical. I want to fix this by relocating either the leaf spring foreward eye more toward the rear, or the shackle mount foreward. What will work best, and how should I go about it?

B) I want to make some longer shackles to regain the lost height that I will incur from the lesser shackle angle (or greater, depending how you look at it). Has anyone done this? How did you go about this/how should I go about this? Or am I completely stupid for wanting to do this?

Yes, I did use the search button, but everything I found on the subject was not thorough enough. I found nothing about homemade shackles.

Thanks guys!

B) I want to make some longer shackles to regain the lost height that I will incur from the lesser shackle angle (or greater, depending how you look at it). Has anyone done this? How did you go about this/how should I go about this? Or am I completely stupid for wanting to do this?

Yes, I did use the search button, but everything I found on the subject was not thorough enough. I found nothing about homemade shackles.

Thanks guys!

Last edited: