93_xj

NAXJA Forum User

- Location

- Hampton, VA

How its done:

My buddy whos going to school in ohio to be a deisel mechanic. His teacher drives an 03 wrangler with a 4.0 and was able to get some pretty significant gas mileage numbers with it. He claims that he gets 30 mpg on the highway.

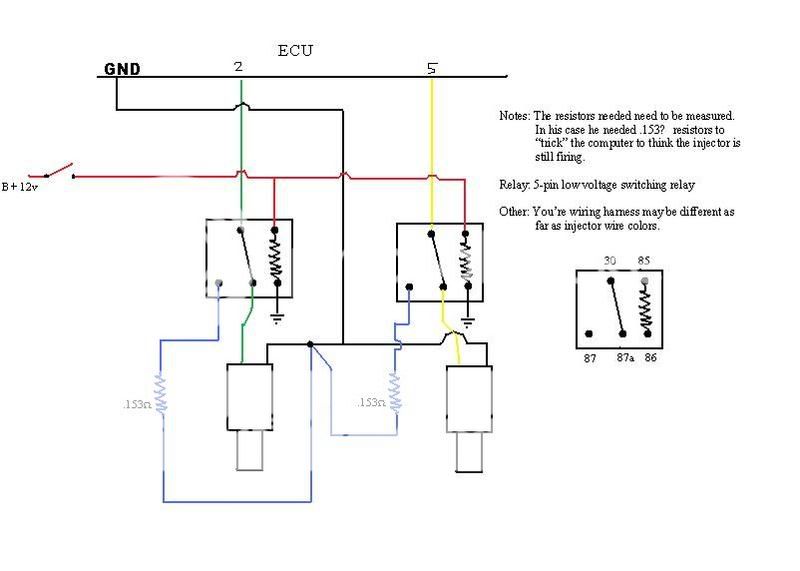

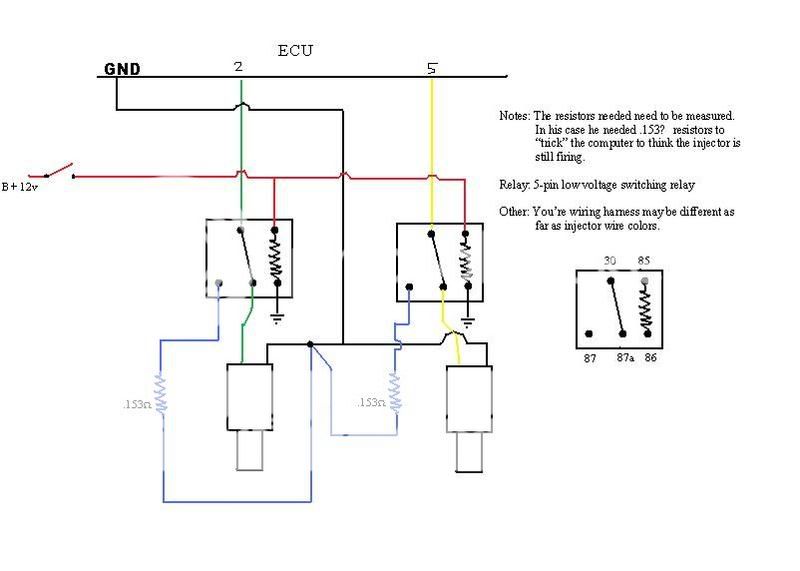

What he did was put 5 pin relays on cylinders 2 and 5 (because they are running partners when one is firing the other is exhausting) and wired them so that when he set his cruise control (also can be done with switch) and his torque converter went into lock-up, his injectors "shut off" making his 6 cylinder act as a 4. He then went ahead and added a resistor with the same resistance as a running injector to make the computer think they were still spraying.

Diag

My buddy whos going to school in ohio to be a deisel mechanic. His teacher drives an 03 wrangler with a 4.0 and was able to get some pretty significant gas mileage numbers with it. He claims that he gets 30 mpg on the highway.

What he did was put 5 pin relays on cylinders 2 and 5 (because they are running partners when one is firing the other is exhausting) and wired them so that when he set his cruise control (also can be done with switch) and his torque converter went into lock-up, his injectors "shut off" making his 6 cylinder act as a 4. He then went ahead and added a resistor with the same resistance as a running injector to make the computer think they were still spraying.

Diag