Love2Ride450

NAXJA Forum User

- Location

- Roseburg, Oregon

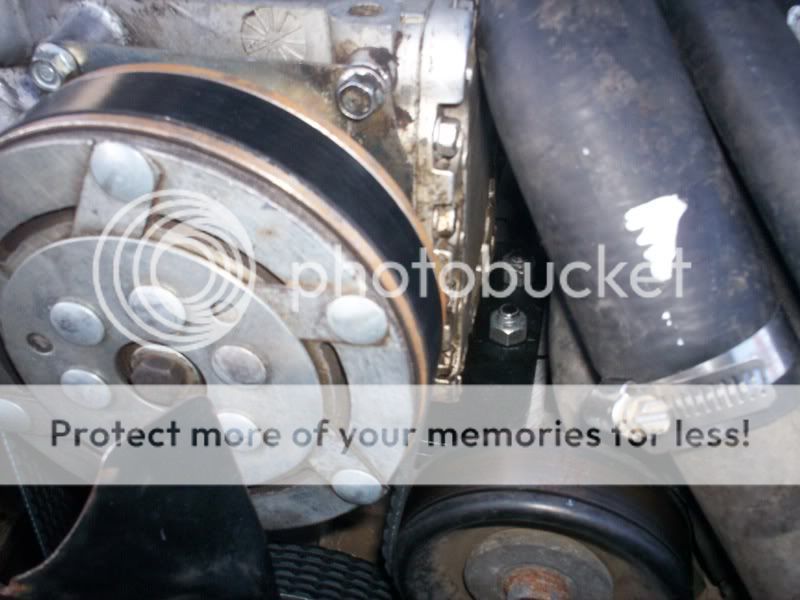

I know, it's been discussed lots, but I haven't found any info specifically on what I want to do. I would very much like to mount a York on my factory AC bracket. It appears that I will have to move the battery, but I want to know if anybody has done it or not. I don't have the original pump anymore. I traded it to a friend for the AC delete pulley. I thought he was going to use it for AC, and I didn't want AC, so I figgered I'd help him out. Well he built OBA from it, and this was before I knew about using a sanden with a tool oiler. Anyway, I picked up a York 209 for $FREE$, but it has a v belt clutch on it. It has the suction on the right side. I want to lay it on it's side, on my factory bracket. Can it be done? I have the bracket that uses four bolts from the top to fasten the stock compressor.

Where can I find a cheap serpentine clutch? I already searched the junk yards in my area to no avail.

I would also like to see where everybody installed air tanks, and what sizes they use. Pro's/Con's?

TIA, Josh

Where can I find a cheap serpentine clutch? I already searched the junk yards in my area to no avail.

I would also like to see where everybody installed air tanks, and what sizes they use. Pro's/Con's?

TIA, Josh