i'm currently running 3.5 inches of lift and plan on doing an axle swap very soon (hp d44 full-width) with the tnt truss i have already purchased. however i plan on more lift some time later about a total of 6.5 to 7.5 inches so what degree pinion angle should i look at installing the truss at? what about castor? Also does anyone have picks of this and how you did the trackbar mount. thanks.

-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TnT hpD44 truss help

- Thread starter aaronsxj

- Start date

Prepmech

NAXJA Member #981

- Location

- Neoga/Decatur, IL

aaronsxj said:Also does anyone have picks of this and how you did the trackbar mount. thanks.

What kind of steering are you going to be running. I used the JKS bracket, but I am running the stock ford knuckles with 1-ton chevy TREs OTK. T&T makes a nice bracket if you are going to run high steer.

The best way to figure out your pinion angle is to mock everything up before welding anything. Make sure to measure the hight of your springs with weight on them before you take everything apart. You'll want your pinion angle just slightly higher than the driveshaft angle, by about 1 degree.

You'll want to run 5-8 degrees of caster.

about the steering, not sure what i was going to do. would like to go highsteer but needed to know what route i should go, chevy, jeep, aftermarket, and if i go chevy, not quite sure how to do so with keeping it 5 on 5.5 wheel pattern. what are some options?

Prepmech

NAXJA Member #981

- Location

- Neoga/Decatur, IL

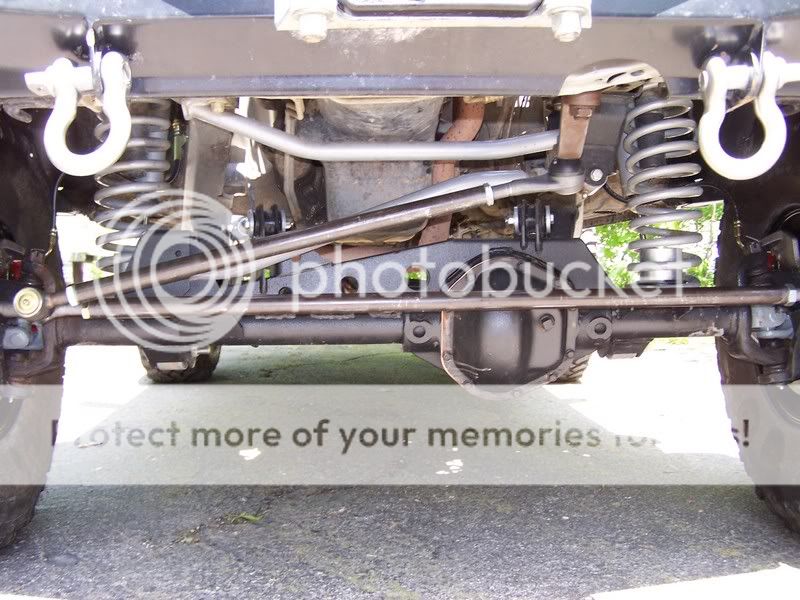

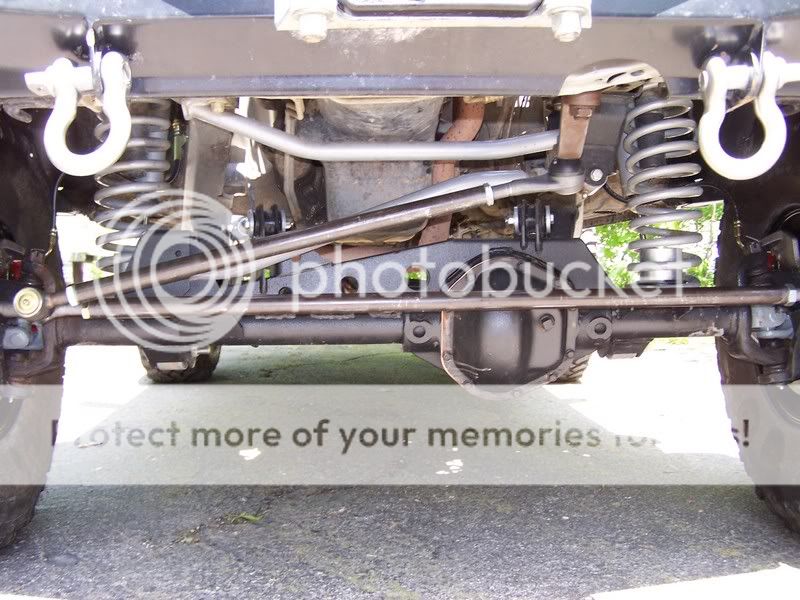

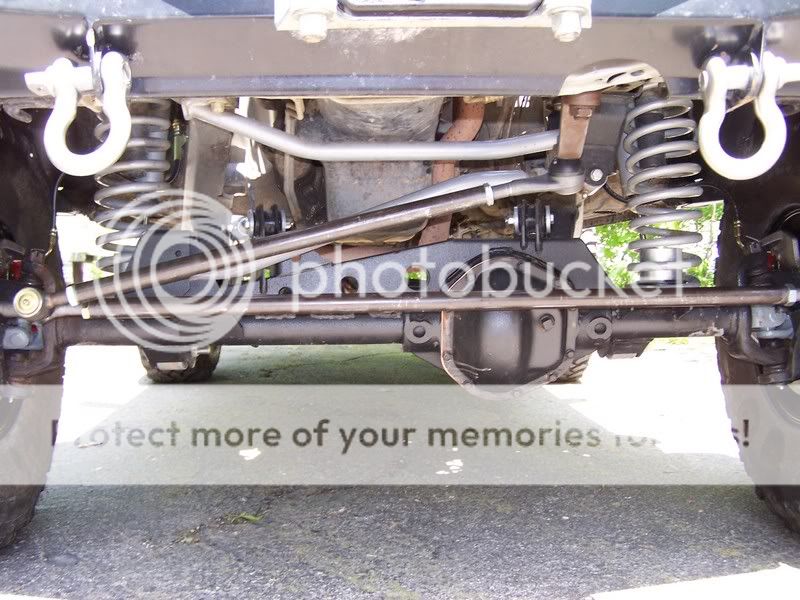

I'm running the ford knuckles that came on my axle, reamed for 1-ton TREs over the knuckle, JKS trackbar mount. Its cheap, easy, but not quite as nice as high steer.

Sierra Drifter

NAXJA Forum User

- Location

- San Ramon Ca

aaronsxj said:i'm currently running 3.5 inches of lift and plan on doing an axle swap very soon (hp d44 full-width) with the tnt truss i have already purchased. however i plan on more lift some time later about a total of 6.5 to 7.5 inches so what degree pinion angle should i look at installing the truss at? what about castor? Also does anyone have picks of this and how you did the trackbar mount. thanks.

I'm running a hp d44 full width from a 78 F250 and about 7 1/2" of lift. I set the castor to 5* and didn't worry about pinion angle because I feel correct castor is more important. The hp dana 44 pinion looks pretty close to where it should be. I used an angle finder on a large dowel that I placed through the ball joint holes on the inner C's to set the caster at 5* and then welded the coil spring mounts level.

See the link in my sig for a full write-up and a ton of pictures of how I did it. I did not worry about rotating the inner C's. I know its not perfect, but this setup works just fine for me, no wooble, no vibes, no bumpsteer and I drive it on the freeway at 75 mph on 37's.

Sierra Drifter

NAXJA Forum User

- Location

- San Ramon Ca

Prepmech said:I'm running the ford knuckles that came on my axle, reamed for 1-ton TREs over the knuckle, JKS trackbar mount. Its cheap, easy, but not quite as nice as high steer.

Your setup looks very similar to mine, the TnT truss wasn't available when I did mine, I used a RE bracket kit.

Same JKS track bar relocation bracket.

Same RE track bar brace

Same inverted T steering configuration with Chevy 1 ton tres

Even the recovery shackles and winch fairlead are very similar.

Nice job!

Last edited:

Prepmech

NAXJA Member #981

- Location

- Neoga/Decatur, IL

aaronsxj said:tried to look at the link in your sig, but wouldn't let me look at the pics, then i tried to join the forum and they said no free-email accounts, but thanks for the info. is that the 50$ jks over-axle track bar mount on the TnT truss?

yeah, thats what I'm running.

Prepmech

NAXJA Member #981

- Location

- Neoga/Decatur, IL

I cut my knuckles loose, set my caster and pinion angle, welded on the inner knuckles, welded on the truss, the coil buckets weld to the truss, then welded on the lower control arm mounts, and finally welded on the trackbar mount.

Prepmech

NAXJA Member #981

- Location

- Neoga/Decatur, IL

aaronsxj said:with the truss did you need to weld it to the center section?

you don't need to, and they (T&T) actually say not to.

Prepmech

NAXJA Member #981

- Location

- Neoga/Decatur, IL

Nope, call T&T and talk to someone who actually works on jeeps, not just a counter person. They are great to do business with and can answer any questions you may have.

Prepmech

NAXJA Member #981

- Location

- Neoga/Decatur, IL

5 lug Ford knuckles

Similar threads

- Replies

- 24

- Views

- 7K

- Replies

- 10

- Views

- 4K

- Replies

- 19

- Views

- 3K