- Location

- Southern Maryland

haha made you look at my problem!

I have this hand-me-down beater 91 Lardo, which has a small mystery roof leak, the seats are blown out, and a couple of other interior problems. So I figured strip it down, R&R the interior problems, then herculine it and put it back together with whatever replacement trim I need.

When I got the carpet out I found a little surface rust up front (not too bad), but I also found this:

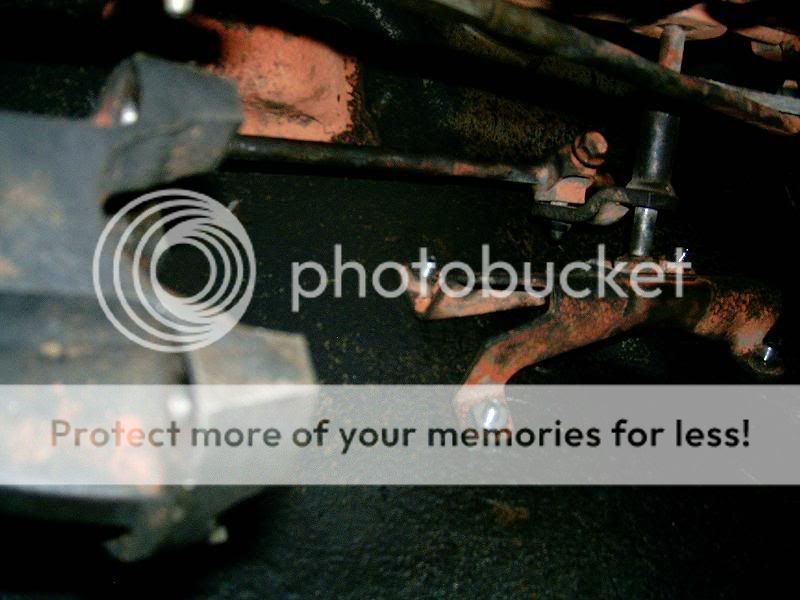

That's pretty bad. I can pretty much get the rear left shock removed through that hole. The support metal that goes down to the back seat is also pretty bad (both sides):

...and there are also a couple of smaller holes by the striker (hard to tell with paint spill but there are two holes there):

I talked to my buddy with a body shop and we agree that I should order the replacement rear floorpan from jeep4x4center, cut out the old deck and weld the new one in. Total cost for materials and his time will be less than $1k so it's acceptable, since that is the only major damage. The floorpan is for the later body style but the decking part looks to be the same, so I don't think it will be a problem. Does anybody know if it will work?

I am thinking that since I am here already that I should do some other repairs. For example, we have to drop the old gas tank out to repair the decking, and the gas gauge on this beater does not work correctly, and I'm guesing the fuel pump and whatnot probably needs replacing after 334k miles... so I might as well put in a new tank, pump, sender, the works. I see some mention of 20 gallon tanks, are those an option? Anything I need to take into consideration here?

I am planning to see if I can do a GC heated seat upgrade while I'm messing with this. I'll need to weld in support brackets and will have to sink a couple of new studs and run new wiring so I should probably do all that before I herculiner the floor.

Should I go ahead and replace the heater core while I've got everything out? It's never been replaced and the AC doesn't work so I shouldn't need to discharge anything.

I am planning to swap in an NP242, so should I do that now, or will it not matter?

Should I do any body mods like the rear corner cut-and-fold before I herculiner and primer the repairs? Anything else I should do?

BTW what are the four bolts on the side of the hump for? They are rusted and need to be replaced but I don't want to damage anything.

What should I do while she's naked?

Thanks!

I have this hand-me-down beater 91 Lardo, which has a small mystery roof leak, the seats are blown out, and a couple of other interior problems. So I figured strip it down, R&R the interior problems, then herculine it and put it back together with whatever replacement trim I need.

When I got the carpet out I found a little surface rust up front (not too bad), but I also found this:

That's pretty bad. I can pretty much get the rear left shock removed through that hole. The support metal that goes down to the back seat is also pretty bad (both sides):

...and there are also a couple of smaller holes by the striker (hard to tell with paint spill but there are two holes there):

I talked to my buddy with a body shop and we agree that I should order the replacement rear floorpan from jeep4x4center, cut out the old deck and weld the new one in. Total cost for materials and his time will be less than $1k so it's acceptable, since that is the only major damage. The floorpan is for the later body style but the decking part looks to be the same, so I don't think it will be a problem. Does anybody know if it will work?

I am thinking that since I am here already that I should do some other repairs. For example, we have to drop the old gas tank out to repair the decking, and the gas gauge on this beater does not work correctly, and I'm guesing the fuel pump and whatnot probably needs replacing after 334k miles... so I might as well put in a new tank, pump, sender, the works. I see some mention of 20 gallon tanks, are those an option? Anything I need to take into consideration here?

I am planning to see if I can do a GC heated seat upgrade while I'm messing with this. I'll need to weld in support brackets and will have to sink a couple of new studs and run new wiring so I should probably do all that before I herculiner the floor.

Should I go ahead and replace the heater core while I've got everything out? It's never been replaced and the AC doesn't work so I shouldn't need to discharge anything.

I am planning to swap in an NP242, so should I do that now, or will it not matter?

Should I do any body mods like the rear corner cut-and-fold before I herculiner and primer the repairs? Anything else I should do?

BTW what are the four bolts on the side of the hump for? They are rusted and need to be replaced but I don't want to damage anything.

What should I do while she's naked?

Thanks!

Last edited: