Stumpalump

NAXJA Forum User

- Location

- Franktown Co.

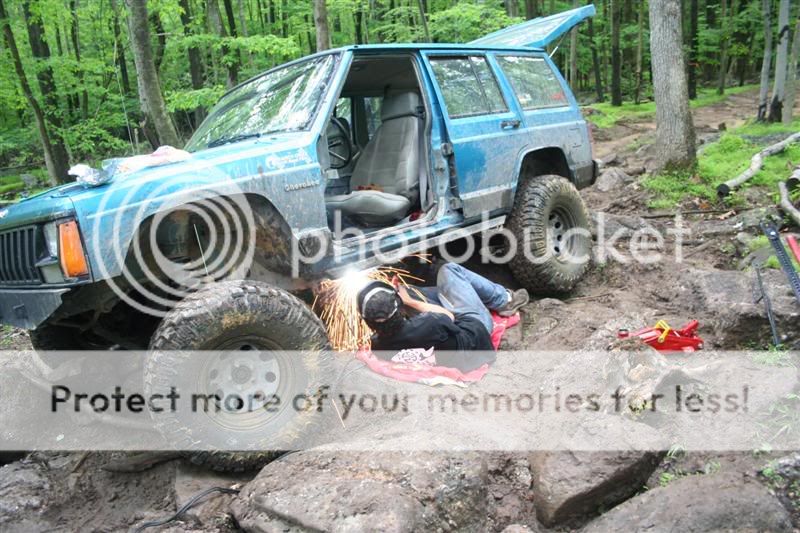

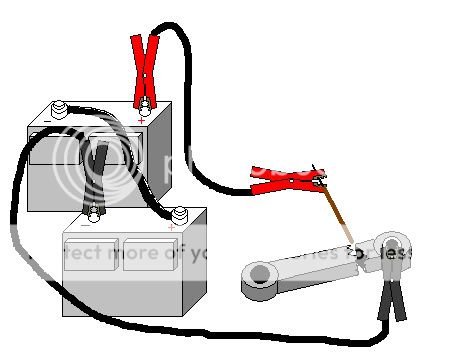

I watched FrankZ weld up a broken controll arm on a buggy this weekend using at first two and then 3 batteries. How about using a jeep battery and a motercycle battery? or two motercycle and a jeep battery. Anybody ever actually tried this battery welding and can you share your experiance? What rods work best and do you use negative ground with a DC rod? I'm thinking a couple of motercycle batteries to get the voltage up may do it or is it the current from the large batteries that does it? Can it be done with one battery and a small rod in a pinch?