selarep

NAXJA Forum User

- Location

- Central CA

I'm looking for a DIY for leaf spring clamps if there is one. I called autozone and kragen and they have ONE clamp both in stock and they are different sizes. so I need to brew something up myself....

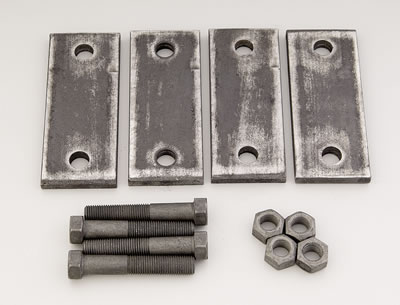

By the looks of it, this is a basic kit:

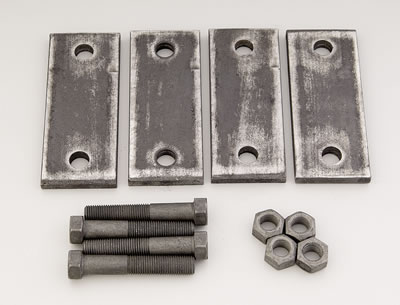

this turns into:

So is that it? Any one have any measurements of how far the holes should be? or bolt length?

By the looks of it, this is a basic kit:

this turns into:

So is that it? Any one have any measurements of how far the holes should be? or bolt length?