markaboo929

NAXJA Forum User

- Location

- Mooresville,NC

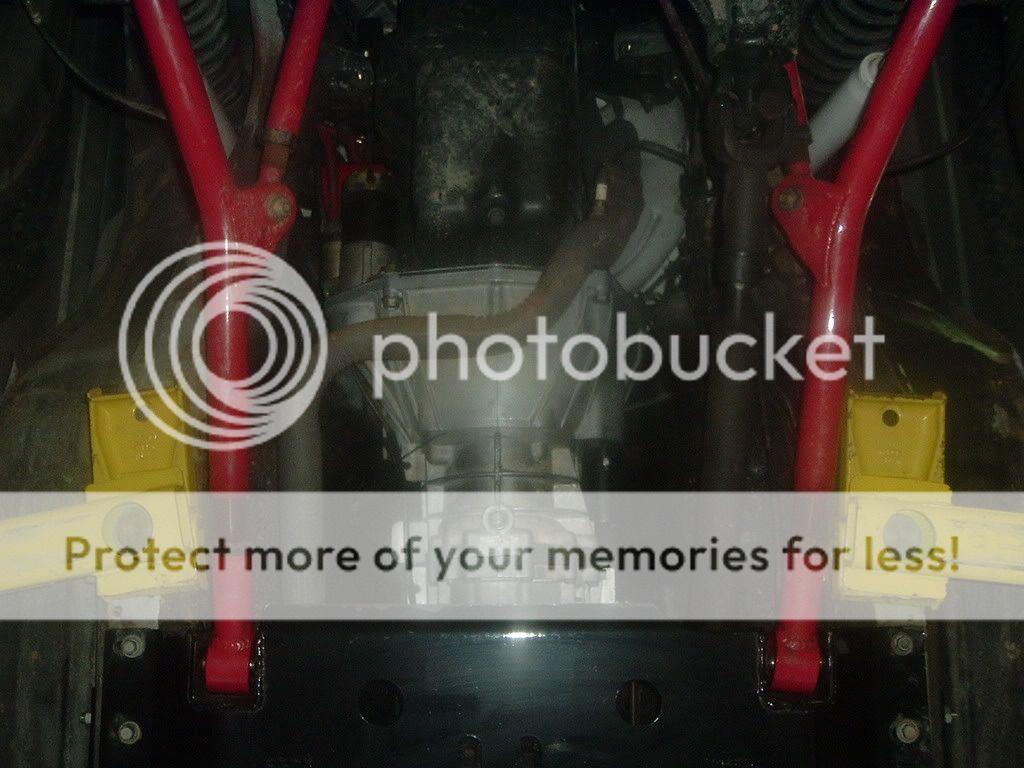

Well,here's the deal.I have been looking for a good performance clutch that will handle the stress that off-roading/rock krawling does to a clutch set and the heat build up that is generated by constant slippage in the rocks and the like.I have been looking at Spec clutches and the dual friction one from Centerforce.The Spec one is a Kevlar faced clutch disc designed for heat loading.Further searching lead me to ZOOM Clutches,which also makes a performance clutch.I noticed that the company is 3 exits from my current work place here in Charlotte,NC.I contacted them directly on the phone to see if they sold publicly,they do not, I spoke with a product engineer there and was told they are producing a clutch kit for jeeps,get this,it will consist of a CRYOGENIC proccesed flywheel,CRYOGENIC performance pressure plate,and a pure 100 % Kevlar disc,wait it gets better-well for me anyways-Uppon further conversation with him,Chris,he mentioned that he may be able to give one away for testing,that was yesterday.I went there today to visit the facility and after talking with the operations manager he came out and looked at my XJ and is giving me a kit to test for them!!!! SAAAAWWWEEETTTTT!!! They have designed it specifically for jeep applications that see high slippage and heat build up,hence the CRYO proccess.I think this is really excellent of them to come up with such a product for us hardcore,diehard manual trans jeepers.Of course I will need to provide them with technical data and testing results as there goal is to mantain a steetable,high abuse clutch kit.Sounds like they are on to some new inovative ideas.What do you guys/gals think of this kind of clutch set up? any questions or comments on what I really need to do to help with the testing procees?The kits are not even on there site yet,actually when i went there they were packaging these units,pretty impressive high quality stuff.