IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

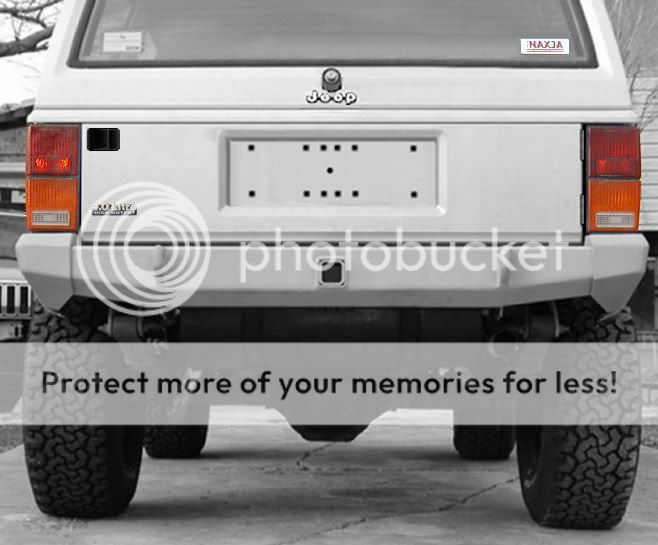

What I want it to look like (not my jeep just the only good level rear pic I could find on  )

)

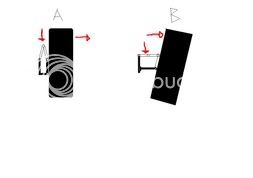

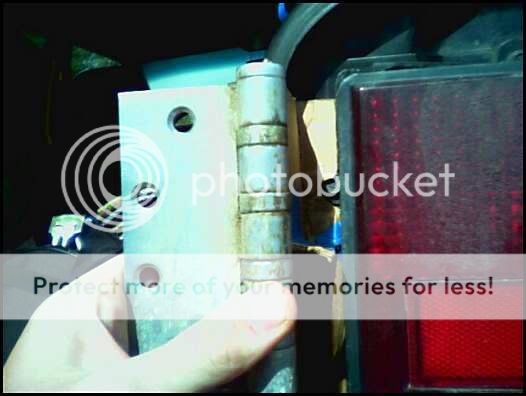

Where I want to move the stock lock, and Jeep Emblem

Where I think I should put reinforcment in the new hatch/door to support the weight of a tire, jerry cans, and high lift jack.

What do you guys think? Is it feesible/a good idea? I'm kinda on a low budget $200-300, possible/impossible?

Any tips or help would be great, TIA

Jackson

)

)

Where I want to move the stock lock, and Jeep Emblem

Where I think I should put reinforcment in the new hatch/door to support the weight of a tire, jerry cans, and high lift jack.

What do you guys think? Is it feesible/a good idea? I'm kinda on a low budget $200-300, possible/impossible?

Any tips or help would be great, TIA

Jackson