My stock cossmember had taken a beating and down here in Australia parts for Jeeps are more expensive than the US due to a smaller market etc so I decided to take a spare crossmember and beef it up.. Be kind, I've only had the welder for a month and this is my first large project with it

First I cut the bottom off the stock crossmember

Then stripped it back

Went and got some steel to plate it with (It's 8mm and will be used to replace the stock tcase skid as well)

Next I cut it to shape, drilled some holes for accessing the mount studs. Also drilled 4 holes and welded some nuts on the back for mounting the tcase skid and then started to weld it all up.

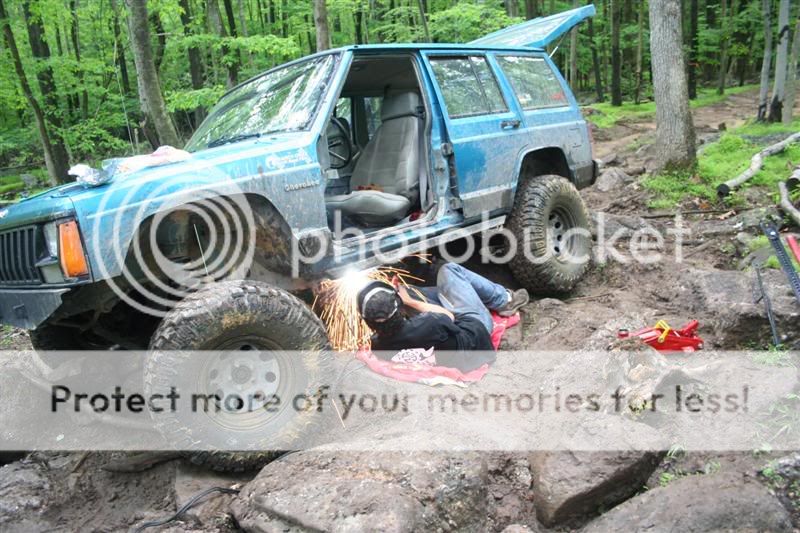

And my welding, I got better as I went along, welding 8mm plate to the thin stuff wasn't easy for me either. Seems good and solid though.

Now I just need to trim it up, bend the ends to follow the crossmember profile and finish welding it

Cheers

Steve

First I cut the bottom off the stock crossmember

Then stripped it back

Went and got some steel to plate it with (It's 8mm and will be used to replace the stock tcase skid as well)

Next I cut it to shape, drilled some holes for accessing the mount studs. Also drilled 4 holes and welded some nuts on the back for mounting the tcase skid and then started to weld it all up.

And my welding, I got better as I went along, welding 8mm plate to the thin stuff wasn't easy for me either. Seems good and solid though.

Now I just need to trim it up, bend the ends to follow the crossmember profile and finish welding it

Cheers

Steve