87xjco

NAXJA Forum User

- Location

- Denver, CO

http://naxja.org/forum/showthread.php?t=69712

This thread is so big. I thought I would put the sheet metal work on a seperate thread.

Some people have asked for more pictures of the sheet metal work especially where the 2 different fenders are spliced together.

Here is how I joined the two fenders together

The 1st step was to cut off the back lip of the XJ fender leaving as much of the fender intact as I could.

Next I cut off the rear lip of the Toyota fender making sure I had plenty of metal to overlap the XJ fender. Then bolted it back up to the truck and made sure I was happy with the gap between door and fender.

Then I started using dollie and hammer to make some of the body lines and bends in the Toyota fender transfer onto the Jeep fender.

For some of the body lines it is easiest to use the edge of a metal table and a body hammer to make the bends.

Of course some of the Jeep lines need to flatten out.

I had to keep holding the Jeep fender up to the Toyota fender and continue shaping the fender

No need to get it perfect now. All the welding is going to cause warping even if your carefull.

Once I got it all fitting good and checked the front edge of the fender to make sure it was at the right position, I marked the edge where the fenders overlap.

Then I ran a pice of tape over that line with the line set slightly to the right of center. This distance will match the flange that my flanging tool will make. Then I trimmed the Jeep fender to the edge of the tape.

Then I sanded off the primer along the edge and re-fit the fender and marked the edge on the bare metal.

Then I used the flanging tool

To make a flanged edge like this

Then I trimmed on the Toyota fender until I had a gap that could be filled. Then one spot weld at a time welded up about an inch.

Then I moved on to another spot so I wouldn't warp the metal too badly and worked my way down the entire seam.

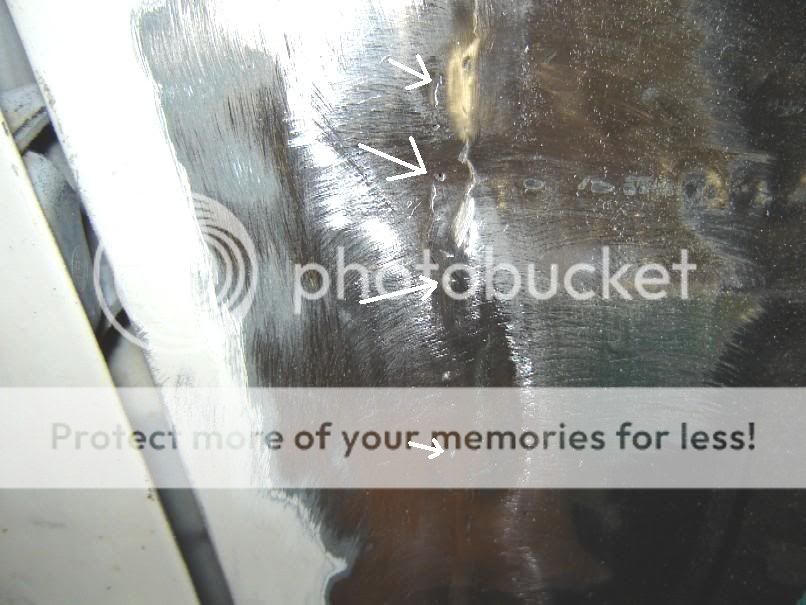

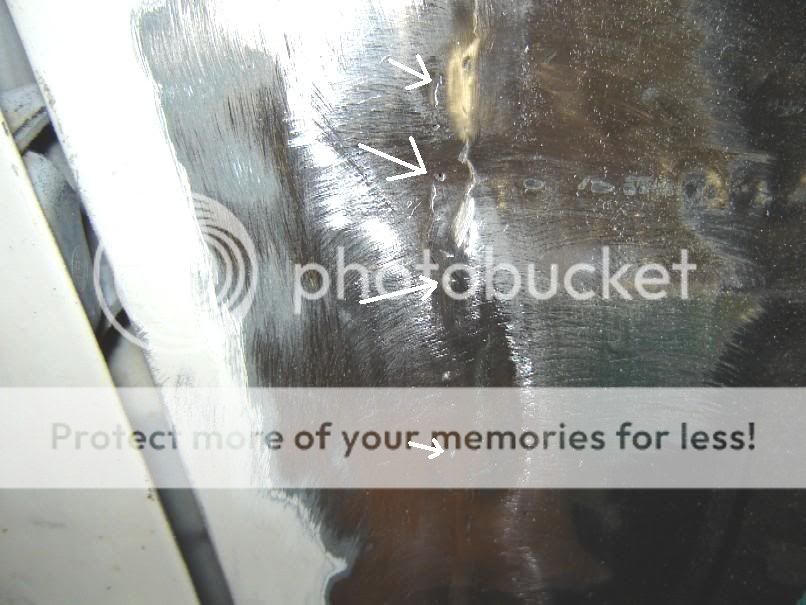

It's not pretty but eventually I got the gap filled

I mostly used a grinder like this. I took care when grinding to only grind on the weld and very little of the panels around the weld. It is easy to grind thru the panels if you are not carefull.

I have some pits and holes that I will need to weld and grind smooth. There will be alot more dollie work with the fender off. But it's important to keep test fitting the fender and making sure a good gap with the right contour to match the door is maintained. I'll keep working on it.

I'll post some more when I do the bondo work and also when I narrow the rear of the hood, that will be fun!!

This thread is so big. I thought I would put the sheet metal work on a seperate thread.

Some people have asked for more pictures of the sheet metal work especially where the 2 different fenders are spliced together.

Here is how I joined the two fenders together

The 1st step was to cut off the back lip of the XJ fender leaving as much of the fender intact as I could.

Next I cut off the rear lip of the Toyota fender making sure I had plenty of metal to overlap the XJ fender. Then bolted it back up to the truck and made sure I was happy with the gap between door and fender.

Then I started using dollie and hammer to make some of the body lines and bends in the Toyota fender transfer onto the Jeep fender.

For some of the body lines it is easiest to use the edge of a metal table and a body hammer to make the bends.

Of course some of the Jeep lines need to flatten out.

I had to keep holding the Jeep fender up to the Toyota fender and continue shaping the fender

No need to get it perfect now. All the welding is going to cause warping even if your carefull.

Once I got it all fitting good and checked the front edge of the fender to make sure it was at the right position, I marked the edge where the fenders overlap.

Then I ran a pice of tape over that line with the line set slightly to the right of center. This distance will match the flange that my flanging tool will make. Then I trimmed the Jeep fender to the edge of the tape.

Then I sanded off the primer along the edge and re-fit the fender and marked the edge on the bare metal.

Then I used the flanging tool

To make a flanged edge like this

Then I trimmed on the Toyota fender until I had a gap that could be filled. Then one spot weld at a time welded up about an inch.

Then I moved on to another spot so I wouldn't warp the metal too badly and worked my way down the entire seam.

It's not pretty but eventually I got the gap filled

I mostly used a grinder like this. I took care when grinding to only grind on the weld and very little of the panels around the weld. It is easy to grind thru the panels if you are not carefull.

I have some pits and holes that I will need to weld and grind smooth. There will be alot more dollie work with the fender off. But it's important to keep test fitting the fender and making sure a good gap with the right contour to match the door is maintained. I'll keep working on it.

I'll post some more when I do the bondo work and also when I narrow the rear of the hood, that will be fun!!