offroadman73

NAXJA Forum User

- Location

- McAllen, Texas

any one running a custom transfer case skid that does not rob any ground clearence? i would like to have one built. any pics??

junk, but works if its all ya got...for a whilexjj33p3r said:Rusty's has one that bolts to the frame and stock crossmember.

Exactly. It'll work for a while. Also, DPG has a whole skid that covers the stock cross member, and goes further back as well. 3/16", so it's pretty good I guess.Ramsey said:junk, but works if its all ya got...for a while

xjj33p3r said:Exactly. It'll work for a while. Also, DPG has a whole skid that covers the stock cross member, and goes further back as well. 3/16", so it's pretty good I guess.

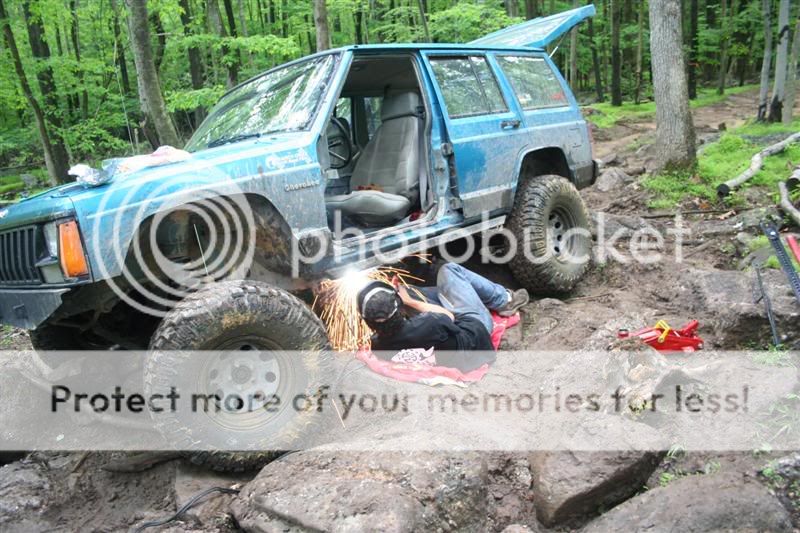

Hey Jes, got any write ups on the type of frame reinforcement you did on your jeep?Jes said:Mine...

xjj33p3r said:Rusty's has one that bolts to the frame and stock crossmember.

devildog0 said:

xjj33p3r said:Hey Jes, got any write ups on the type of frame reinforcement you did on your jeep?

That's two of you who don't like the Rust'y plate. What is going on with thiers? On that note, it looks very similar to SkidRow's. This is information I need to know.XJ_ranger said:dosent work too well for the ax-15 guys...

i need to "modify" mine, or put it on my sister's jeep...

ajpulley said:That's two of you who don't like the Rust'y plate. What is going on with thiers? On that note, it looks very similar to SkidRow's. This is information I need to know.