Yucca-Man

NAXJA Member # 683

- Location

- Castle Rock, CO

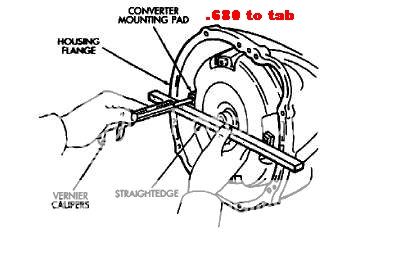

I'm 99% of the way there with reinstalling my AW-4 after replacing the bellhousing. The problem I'm having is that the torque converter appears not to want to seat in the flexplate as I've got about 1/2" to go before it all lines up. I've tried wiggling and shaking it every which way I can but it won't quite make it.

How the $^%$ do you get it to seat? Before going too much farther with that train of thought though, how can I be sure the TQ is actually seated all the way? When I went to reinstall that on the tranny it seems looser than I remember and had a wee bit of fore-and-aft play in it. Is this normal, or did I not get the TQ all the way on in the first place?

Edit: My inspection mirror appears to have gone on walkabout so I can't see behind the flexplate either..

How the $^%$ do you get it to seat? Before going too much farther with that train of thought though, how can I be sure the TQ is actually seated all the way? When I went to reinstall that on the tranny it seems looser than I remember and had a wee bit of fore-and-aft play in it. Is this normal, or did I not get the TQ all the way on in the first place?

Edit: My inspection mirror appears to have gone on walkabout so I can't see behind the flexplate either..

Last edited: