I am planning on building some rockrails and was toying with some designs, and was just wondering what yall had to say.

thanks guys

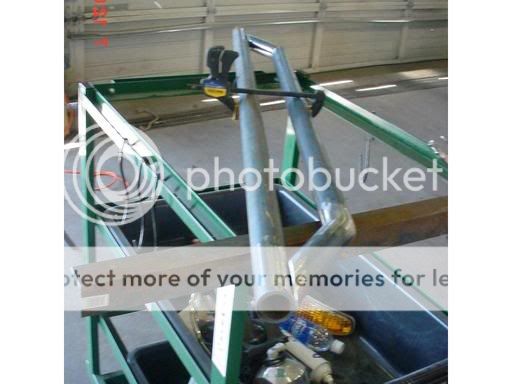

i have not added all the correct measurements yet, but i am thinking something like that, also how should i bolt these to the frame

thanks guys

i have not added all the correct measurements yet, but i am thinking something like that, also how should i bolt these to the frame

Last edited: