GodlovesXJs

NAXJA Forum User

- Location

- Allen, TX

Hi by the way, this is my first post on naxja, but I've got a few questions already.

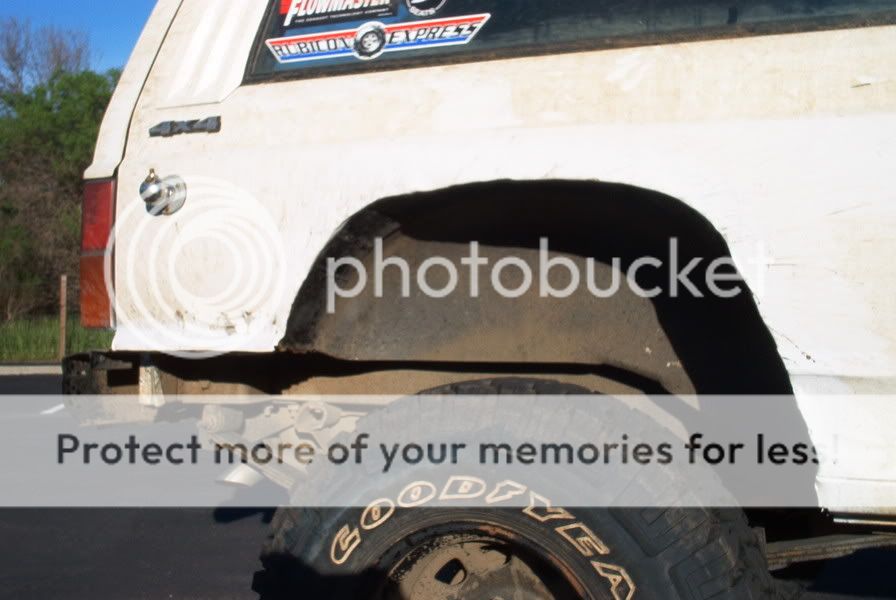

Does anyone know about how much space is above the metal wheelwell liner in the rear?

Because I was thinking of doing some more trimming this summer, probably about another inch. But it'd be nice to know if it was possible just to cut up that extra inch then move up the piece of metal and reweld it into place.

I'd also like to cut my lower rear quarters like

http://www.naxja.org/forum/showthread.php?t=29750&highlight=fender+cutting

Has anyone done that with a 97+ because I have a 98 and there's an extra bracket in there, and I could just remove the bracket and do it exactly like every other year model, but would that sacrifice strength anymore than previous year models or is it exactly the same with just another bracket?

I guess that's about it, any help would be appreciated.

Does anyone know about how much space is above the metal wheelwell liner in the rear?

Because I was thinking of doing some more trimming this summer, probably about another inch. But it'd be nice to know if it was possible just to cut up that extra inch then move up the piece of metal and reweld it into place.

I'd also like to cut my lower rear quarters like

http://www.naxja.org/forum/showthread.php?t=29750&highlight=fender+cutting

Has anyone done that with a 97+ because I have a 98 and there's an extra bracket in there, and I could just remove the bracket and do it exactly like every other year model, but would that sacrifice strength anymore than previous year models or is it exactly the same with just another bracket?

I guess that's about it, any help would be appreciated.