freerider15

NAXJA Forum User

- Location

- FoCo, Crawlorado

After having built a buggy, I've been longing for something simple again, to be able to enjoy the light wheeling, going camping (not because I'm wheeling), longer trips out again.

I've been through all the hoops of an XJ, and after building this:

This XJ should be a walk in the park...or so I "thought".

I'd been thinking about something with maybe 4.5" of lift and 32's, keeping it nice and clean. Well, a close friend of mine Sam (zluster on here), had bought an XJ at auction as a flip (repair and resell). Well, I'd always liked the Jeep (and it was in one of my top 3 colors - Patriot Blue), and had what I was looking for: Low miles, already had a 4.5" Full BDS Lift kit, and more.

So, after selling one XJ that I had for a while, I picked this up from him, since after a few years he hadn't had the time to get it fixed (since he had a real job now).

So enters, the new to me 2001 (and still the newest vehicle I've ever owned).

Specs:

- 2001 XJ - Patriot Blue

- ~105k miles

- Moab 16" wheels

- Brown Dog Motor Mounts

- Newer Aluminum Radiator

- BDS 4.5" Lift Kit

- HP D30 Swapped

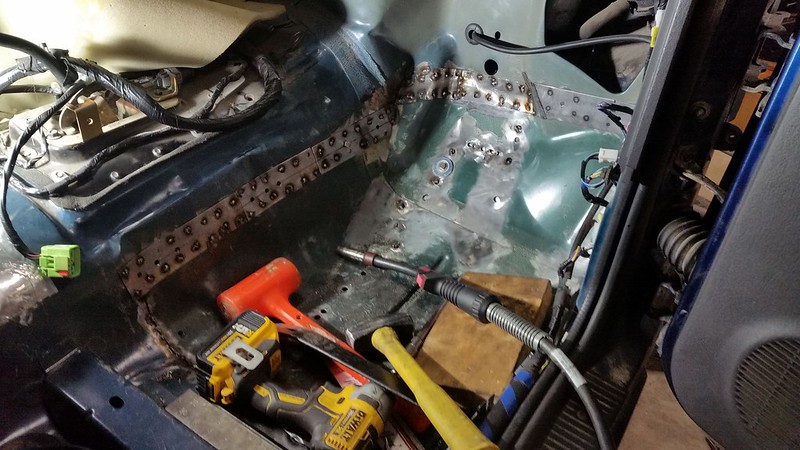

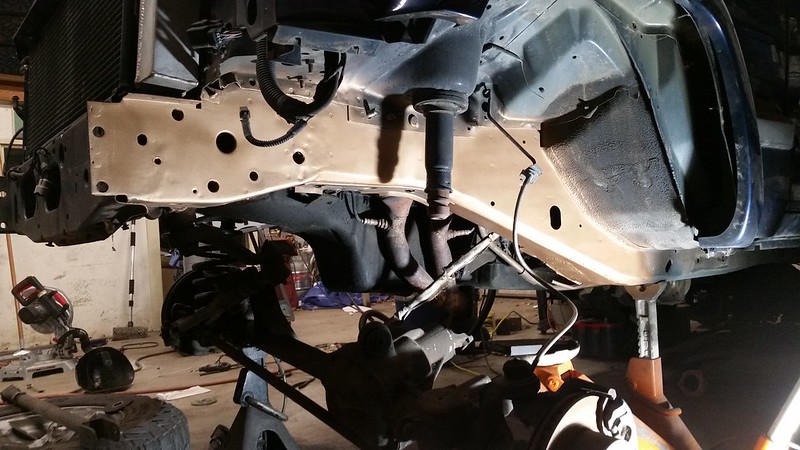

Now, from that picture, all looks pretty good? Well, the fact of the matter is there was some pretty good damage to the passenger side. It looks like the previous owner (prior to Sam), had hit something hard enough with the front right tire to shove it up into the wheel well far enough that it cause some frame and floorwell damage, bent the upper arm mount on that side, and killed the LPD30.

So, I fixed the crossmember mount for Sam (before I bought it), he had done some other work, and swapped in a HP D30.

From there, it's all on me.

Since I've had this for a while, I've been able to acquire parts for...a lot less than MSRP mostly. I'll chronical some of it through the build.

As some know, I'm *rather* anal retentive. I don't like shoddy work, and this build won't be any different. I plan on doing some things a little different, with small touches that make a difference. After building the buggy, other than sheetmetal work...this will be a nice relaxation from custom one off everything .

.

Build plans for this rig (as of this post):

Front HP D30:

- Artec Truss - Acquired

- Zip Locker

- 4.10's

- Ten Factory Axle Seals - Acquired

- WJ Steering Setup - Have several parts acquired

- SOLID Diff Cover - Acquired

- New Coil buckets and LCA's (not quite like most setups however)

Rear: Ford 8.8 (Has 4.10's, Discs, and LSD)

- Complete new brakes

- Artec Truss - Acquired

- SOLID Diff Cover - Acquired

- Shock Mounts - Acquired

- TNT U-Bolt Eliminators - Acquired

Tires:

265/75R16 Goodyear Duratracs on 16" Moabs - Acquired

Other:

- 231J w/ SYE - Came with on rig

- Tera 2Low - Need to pull it out of donor case

- Boostwerks Hidden Winch Comp Mount - On my shelf

- Dirtbound Rear DIY Bumper (no cut/fold) - Acquired

- Dirtbound Front DIY Bumper - Acquired

- Smittybilt 8k winch w/ synthetic - Acquired

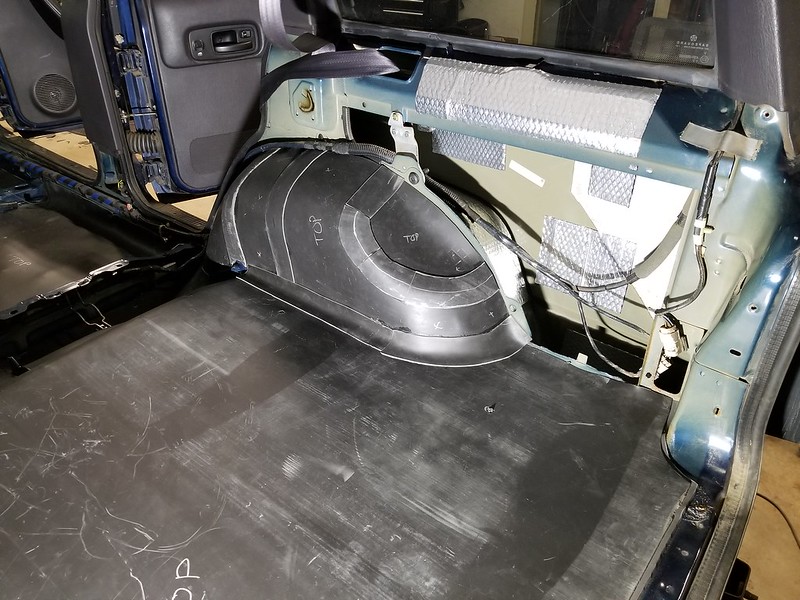

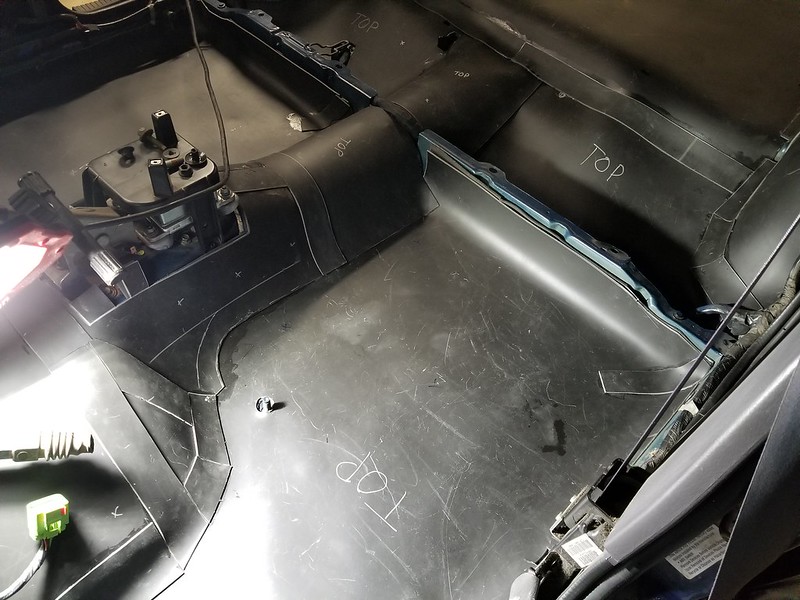

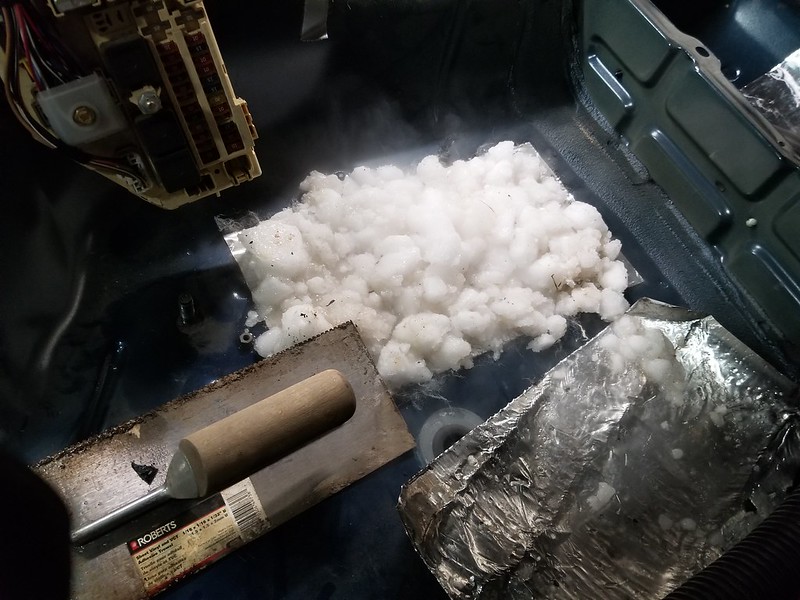

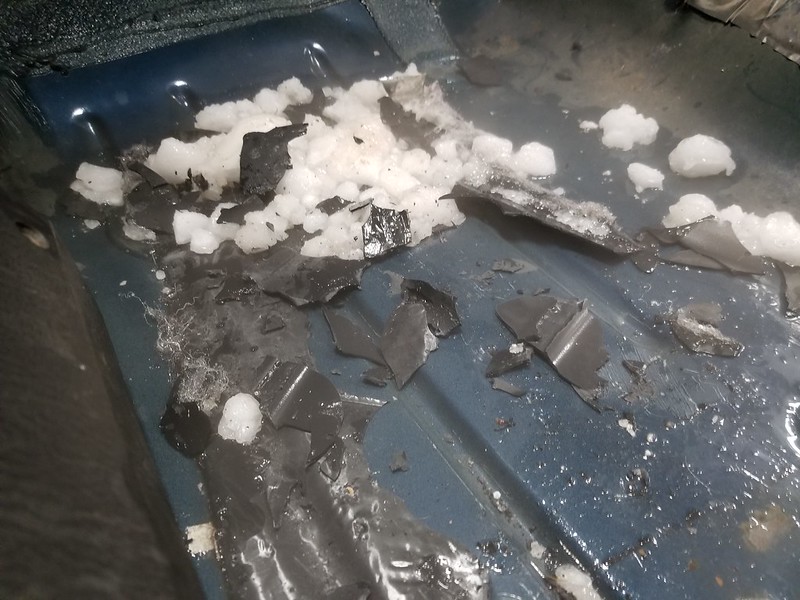

- Full Interior Sound deadening using three stage system (CLD + CCF + MLV)

- Bilstein 5150's front - Acquired

- Bilstein rears

- Tomken Gas Tank Skid - Acquired

- Offroad Armor Rock Rails - Acquired but will have to see if they'll work

So yeah, I've got a buttload of parts sitting in my upper deck area on the shop, ready to go on and get me some more room finally. I know I'm missing some of what I've got sitting up there, but I'll get around to it...

I've been through all the hoops of an XJ, and after building this:

This XJ should be a walk in the park...or so I "thought".

I'd been thinking about something with maybe 4.5" of lift and 32's, keeping it nice and clean. Well, a close friend of mine Sam (zluster on here), had bought an XJ at auction as a flip (repair and resell). Well, I'd always liked the Jeep (and it was in one of my top 3 colors - Patriot Blue), and had what I was looking for: Low miles, already had a 4.5" Full BDS Lift kit, and more.

So, after selling one XJ that I had for a while, I picked this up from him, since after a few years he hadn't had the time to get it fixed (since he had a real job now).

So enters, the new to me 2001 (and still the newest vehicle I've ever owned).

Specs:

- 2001 XJ - Patriot Blue

- ~105k miles

- Moab 16" wheels

- Brown Dog Motor Mounts

- Newer Aluminum Radiator

- BDS 4.5" Lift Kit

- HP D30 Swapped

Now, from that picture, all looks pretty good? Well, the fact of the matter is there was some pretty good damage to the passenger side. It looks like the previous owner (prior to Sam), had hit something hard enough with the front right tire to shove it up into the wheel well far enough that it cause some frame and floorwell damage, bent the upper arm mount on that side, and killed the LPD30.

So, I fixed the crossmember mount for Sam (before I bought it), he had done some other work, and swapped in a HP D30.

From there, it's all on me.

Since I've had this for a while, I've been able to acquire parts for...a lot less than MSRP mostly. I'll chronical some of it through the build.

As some know, I'm *rather* anal retentive. I don't like shoddy work, and this build won't be any different. I plan on doing some things a little different, with small touches that make a difference. After building the buggy, other than sheetmetal work...this will be a nice relaxation from custom one off everything

Build plans for this rig (as of this post):

Front HP D30:

- Artec Truss - Acquired

- Zip Locker

- 4.10's

- Ten Factory Axle Seals - Acquired

- WJ Steering Setup - Have several parts acquired

- SOLID Diff Cover - Acquired

- New Coil buckets and LCA's (not quite like most setups however)

Rear: Ford 8.8 (Has 4.10's, Discs, and LSD)

- Complete new brakes

- Artec Truss - Acquired

- SOLID Diff Cover - Acquired

- Shock Mounts - Acquired

- TNT U-Bolt Eliminators - Acquired

Tires:

265/75R16 Goodyear Duratracs on 16" Moabs - Acquired

Other:

- 231J w/ SYE - Came with on rig

- Tera 2Low - Need to pull it out of donor case

- Boostwerks Hidden Winch Comp Mount - On my shelf

- Dirtbound Rear DIY Bumper (no cut/fold) - Acquired

- Dirtbound Front DIY Bumper - Acquired

- Smittybilt 8k winch w/ synthetic - Acquired

- Full Interior Sound deadening using three stage system (CLD + CCF + MLV)

- Bilstein 5150's front - Acquired

- Bilstein rears

- Tomken Gas Tank Skid - Acquired

- Offroad Armor Rock Rails - Acquired but will have to see if they'll work

So yeah, I've got a buttload of parts sitting in my upper deck area on the shop, ready to go on and get me some more room finally. I know I'm missing some of what I've got sitting up there, but I'll get around to it...

. Those with keen eyes might notice some differences.

. Those with keen eyes might notice some differences.