thanasi85

NAXJA Forum User

- Location

- Sacramento, CA

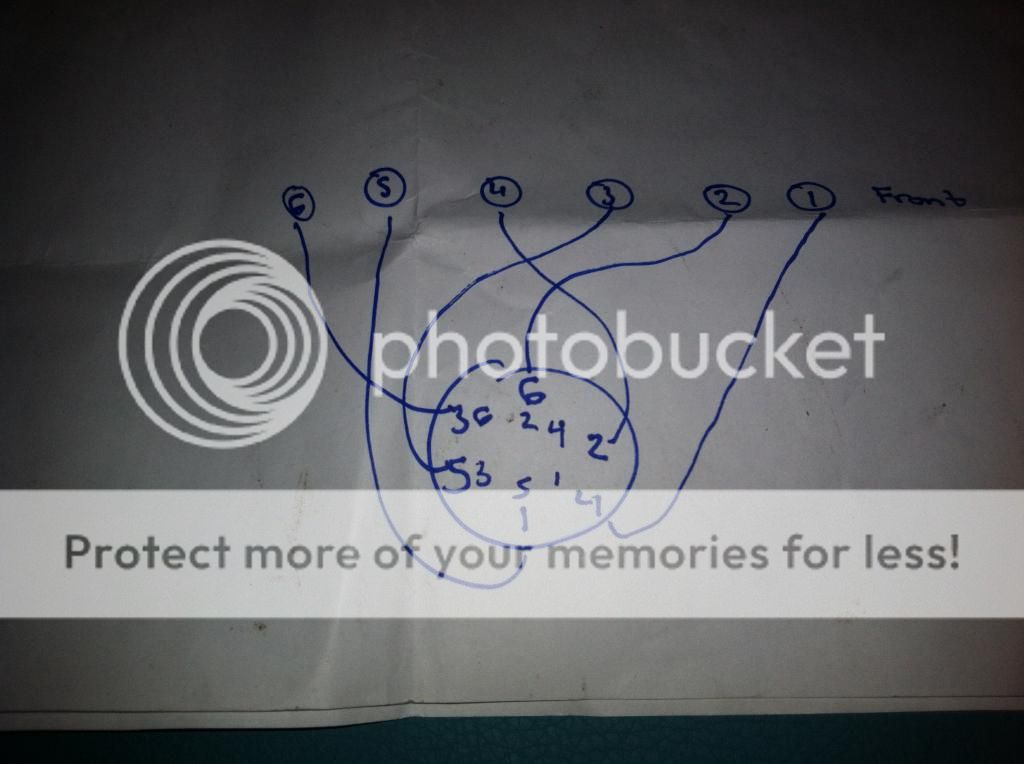

Just bought a new rig 1988 4.0. Doing a tune up today I discovered that all the plug wires are off by one spot going clockwise. The jeep runs so was wondering if anyone had insight as to why this would have been done and if I should move them all back one spot.