WildcatRider

NAXJA Forum User

- Location

- Nashville, TN

Yay.. back again with another XJ electrical problem.. just fixed a #22 Fuel Pump Fuse repeatedly blowing a couple weeks ago and now this. :smsoap:

Sorry this is long, but I provide as much info as possible to help you help me.

Driving to work yesterday, the Jeep suddenly died. Jeep actually started right back up, and I drove to work and back home last night. Started it this morning and it had a CEL.. drove it to work anyway. Also drove it home no problem, with CEL

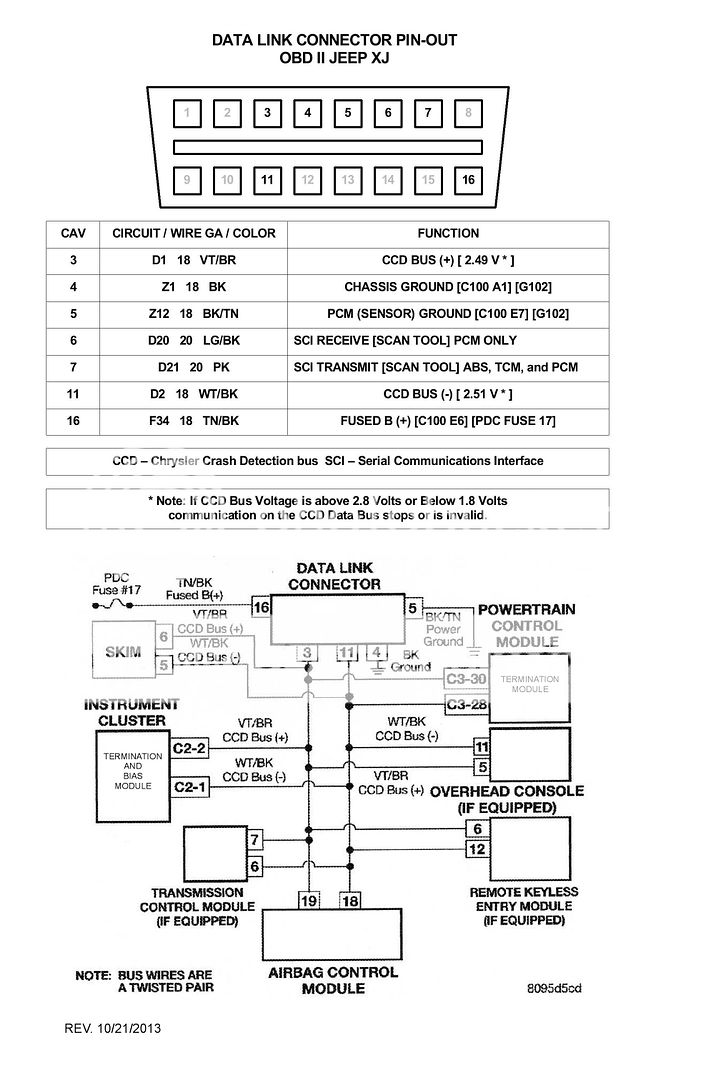

Got it home, saw P1694 (Fault In Companion Module, No CCD messages received from the powertrain control module). Cleared the code and tried to start it... started to turn over but then stumbled and started cranking. Now the thing won't start at all. Has CEL but no codes.

Replaced the crank sensor with a brand new Mopar part I had waiting just for this day, since I read that P1694 might be caused by that. Still no start.

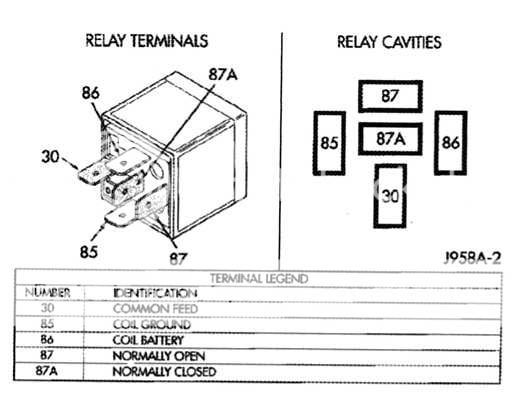

Noticed that when I turn the key, the ASD relay buzzes/clicks very fast for the 1-2 seconds that the fuel pump is supposed to prime.

Testing (not sure what is relevant here)

I have swapped the ASD relay with another one from the PDC, as well as one brand new USA made Tyco relay with the same results.

I am stuck.

Sorry this is long, but I provide as much info as possible to help you help me.

Driving to work yesterday, the Jeep suddenly died. Jeep actually started right back up, and I drove to work and back home last night. Started it this morning and it had a CEL.. drove it to work anyway. Also drove it home no problem, with CEL

Got it home, saw P1694 (Fault In Companion Module, No CCD messages received from the powertrain control module). Cleared the code and tried to start it... started to turn over but then stumbled and started cranking. Now the thing won't start at all. Has CEL but no codes.

Replaced the crank sensor with a brand new Mopar part I had waiting just for this day, since I read that P1694 might be caused by that. Still no start.

Noticed that when I turn the key, the ASD relay buzzes/clicks very fast for the 1-2 seconds that the fuel pump is supposed to prime.

Testing (not sure what is relevant here)

- 12V from 86 to 85 during the 1-2 second prime

- 12V from 30 to 87 (when I jump these pins the Jeep starts with no problem)

- Full battery voltage from 85 to bat+ but 15 ohms from 85 to bat-

I have swapped the ASD relay with another one from the PDC, as well as one brand new USA made Tyco relay with the same results.

I am stuck.