I have a 2000 right hand drive XJ, with a 4.0, automatic and 2 wheel drive. I have been fighting an electrical issue for 6 months and am at my end with this thing, getting ready to start it on fire. The fuse for the O2 system under the hood keeps blowing, but only after the vehicle starts. With the key in the on run position without starting all is well. But after starting the engine, the fuse blows about 3 seconds after. Also the TPS is slow to respond to the pedal being pushed. I have chased every wire and replaced both O2 sensors as well as all sensors under the hood. The ECM shows it was reman in 2012. I am wondering what else the O2 circut shares or what is eatting the fuse after the 3 seconds that is not running before start up? Any help would be great and keep me sane.

-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beating a dead horse. O2 sensor issues.

- Thread starter Jimhd7500

- Start date

8Mud

NAXJA Forum User

- Location

- Central Germany

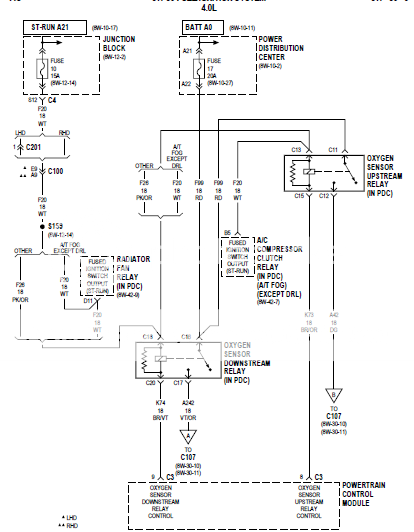

The fuse doesn't power up (have power) until the ASD relay closes. The ASD relay doesn't close until you start (the engine is turning over and the CPS is pulsing). This for a normal XJ, yours may be a different, but similar.

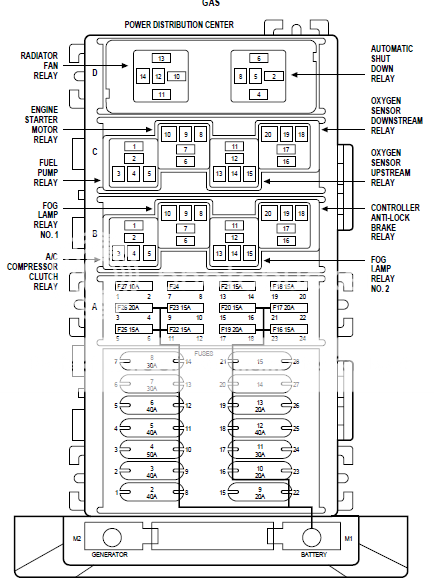

Which fuse number is blowing? Your model is unclear, there are a few differences in the wiring for the European (Euro 3) models and other XJ's. The wiring diagrams are also unclear and poorly labeled. Maybe starting at the fuse number we can figure out a way to troubleshoot exactly what your problem is (or some possibilities).

Just on a hunch pull your upstream O2 relay and your downstream O2 relay and see what happens, if the fuse blows again? If it doesn't blow, plug the relays in one at a time and see which blows the fuse. This is for the Euro 3 model.

I know a lot of people who have had issues with the rear O2 sensor wiring cooking on the exhaust someplace. It may have cooked and melted into a short sometime in the past and is now tucked up out of the way. Inspect it closely for melted spots, run the wire through your finger tips. Pretty much the same for the front O2 sensor wire. Don't get fixated on swapping components out, the problem may well be in the wiring.

Which fuse number is blowing? Your model is unclear, there are a few differences in the wiring for the European (Euro 3) models and other XJ's. The wiring diagrams are also unclear and poorly labeled. Maybe starting at the fuse number we can figure out a way to troubleshoot exactly what your problem is (or some possibilities).

Just on a hunch pull your upstream O2 relay and your downstream O2 relay and see what happens, if the fuse blows again? If it doesn't blow, plug the relays in one at a time and see which blows the fuse. This is for the Euro 3 model.

I know a lot of people who have had issues with the rear O2 sensor wiring cooking on the exhaust someplace. It may have cooked and melted into a short sometime in the past and is now tucked up out of the way. Inspect it closely for melted spots, run the wire through your finger tips. Pretty much the same for the front O2 sensor wire. Don't get fixated on swapping components out, the problem may well be in the wiring.

Last edited:

- Location

- Minneapolis, MN

If you are blowing a fuse you have a short circuit. As 8Mud suggested, you need to look for the cause, and physical damage to the sensor wire harness is the logical place to start.

I have checked all of the wiring, but will do the one O2 sensor at a time and see what is tripping it. It is a Postal right hand drive, built not converted. I understand it is a short but did not know the ASD powering up after the engine starts. Tha is very helpful. Seems they keep the wiring systems in these things top secret. I am a Aircraft mechanic by trade and have been for 20 plus years. I have used my troubleshooting skills to the best of my ability but not having a decent wiring diagram is not helping. I will get back to you and let you know what comes of the O2 testing.

8Mud

NAXJA Forum User

- Location

- Central Germany

I have checked all of the wiring, but will do the one O2 sensor at a time and see what is tripping it. It is a Postal right hand drive, built not converted. I understand it is a short but did not know the ASD powering up after the engine starts. Tha is very helpful. Seems they keep the wiring systems in these things top secret. I am a Aircraft mechanic by trade and have been for 20 plus years. I have used my troubleshooting skills to the best of my ability but not having a decent wiring diagram is not helping. I will get back to you and let you know what comes of the O2 testing.

That the ASD relay doesn't close until the CPS gets a pulse is an assumption, on earlier models it closes as soon as the key is turned to run and pops open again if the PCM (ECU) doesn't get a pulse from the CPS (which actually never really made much sense to me, it always seemed more logical to have it close on a good pulse from the CPS, instead of opening without a good pulse). Exactly when your ASD relay closes and opens is a question I can't answer (my newest model is a 96). But the fuse only blowing after the motor is turning over, seems to indicate this. I may be confusing the fuel pump relay and the ASD relay or even the O2 relays if you have them. It may be part of the circuit from the ignition switch is dead, with the key in the run position? I can usually feel when a relay closes if I hold my finger tip on a relay, though it may take a few tries, that tiny click is subtle.

What fuse number is blowing? Do you have upstream and downstream O2 sensor relays? This may help to nail down which wiring diagram to look at. It my not have anything to do with the ASD relay, it may be the two O2 sensor relays, if your XJ has them. They may only close after the CPS pulses and the PCM closes them. If you have the two O2 sensor relays, pull them both, stick them in one at a time and see which blows the fuse with the engine cranking over, this can possibly cut down your troubleshooting by half.

If we can figure out what wiring diagram to look at or even which is the closest (a 95 maybe), we can trace which circuits share the O2 circuit (and possibly that same fuse) through a splice. It may have nothing to do with the O2 sensors.

Hard to do without a circuit diagram. I usually do pretty well troubleshooting control circuits. I learned on military weapons systems, then later on with industrial machinery and whole building management systems. Most of it is just being dogmatic, using a systematic approach and sticking with it until you find the fault.

8Mud- Thank you for the replies. I have disconnected both of the O2 sensors and it still blew the fuse after startup. It is in the 12 fuse section under the hood. It has 3 rows of 4 each and it is the middle 20amp closest to the engine. The cover does not tell you anything of these fuses or what they are for. I do have an upper and lower O2 relay as well as the ASD and a couple of others. I also checked the system while running with my laptop connected and it shows my throttle at 89% with the engine running at idle, the temp sensor does not update as well as the intake temp. All of the sensors and relays have been replaced as well as the CPS and the TPS. The only one I have not changed is the cam position sensor. It is making me crazy. The TPS does have the 5V signal going to it as well as a good ground, the signal out is what has me confused. It shows 1.2V with the key on and not running and just over 4V when running, and I know thats not right. Even with the TPS disconnected, I get the same voltage.

Keekleberrys

NAXJA Forum User

- Location

- Issaquah

Double tap.

Last edited:

Keekleberrys

NAXJA Forum User

- Location

- Issaquah

All of the sensors and relays have been replaced as well as the CPS and the TPS. The only one I have not changed is the cam position sensor. It is making me crazy. The TPS does have the 5V signal going to it as well as a good ground, the signal out is what has me confused. It shows 1.2V with the key on and not running and just over 4V when running, and I know thats not right. Even with the TPS disconnected, I get the same voltage.

You're probably probing the wrong wires. The TPS is a 3 wire sensor with a 5 volt reference, sensor signal, and a sensor return/signal ground. You can't look at the tps without it plugged in because it gets its reference voltage from the harness. The TPS is a variable potentiometer, so voltage varies with throttle plate position.

To do it right you would need to back probe at the TPS, but it has a weatherpack connector thats kind of a PITA to get backprobes into so I just do it at the PCM.

Remove the cover to the air box, and pop the C1 connector for the PCM out (front most connector), pop the back of the connector off. Insert back probe pins into into pins 23(TPS Signal) and 4(sensor ground/signal return). Plug the connector back into the PCM with the backprobes hooked up and Observe the voltage on your multimeter while actuating the throttle plate with key on engine off.

You can look at all of your computerized engine controls that way you just have to look up the pinouts in the FSM.

Ideal to test the TPS you would look at a trace on an oscilloscope or graphing multimeter and look for smoothness.

Really doubt it has anything to do with your blown fuses though. You would get a P0122 or P0123 if your TPS was doing funky things.

Keeklberrys- I am back probing the TPS when I get those readings with it plugged in. I am also getting the P0122, P0123 and also the P0121. High and low voltage signals at the same time. This thing is a mess. Also, as strange as it sounds, it starts right up and idles normal, just stutters a little when first applying the gas, but evens out.

Last edited:

Keekleberrys

NAXJA Forum User

- Location

- Issaquah

Weird.

Last edited:

8Mud

NAXJA Forum User

- Location

- Central Germany

8Mud

NAXJA Forum User

- Location

- Central Germany

Unplugging the upstream and downstream relays and the O2 sensors and then ohm checking the heater circuit to ground may tell you something.

On the HO XJ's it is my understanding the TPS started out at a high voltage out and the out voltage got lower as the throttle was opened. Just the opposite of the early models. The 2000 is likely to be the same.

A melted O2 sensor wire harness could explain a lot, you may be shorting out your sensor supply circuit and shorting your O2 heater feed or they could even be swapping voltage. Look real closely at the harness where it runs up the front of the motor, on most XJ's it runs very near the exhaust manifold and it is hard to see behind the power steering pump bracket.

I'm just trying to be helpful and maybe learn a little, I have near zero experience with the 2000 model. I'm thinking if it is a factory right hand drive, it is likely to be an export model or maybe a bastard export model with some mixed U.S. and Euro harnesses. Been my experience with export models, that the wiring colors are fairly universal, while the general layout and PDC configuration may be way off.

On the HO XJ's it is my understanding the TPS started out at a high voltage out and the out voltage got lower as the throttle was opened. Just the opposite of the early models. The 2000 is likely to be the same.

A melted O2 sensor wire harness could explain a lot, you may be shorting out your sensor supply circuit and shorting your O2 heater feed or they could even be swapping voltage. Look real closely at the harness where it runs up the front of the motor, on most XJ's it runs very near the exhaust manifold and it is hard to see behind the power steering pump bracket.

I'm just trying to be helpful and maybe learn a little, I have near zero experience with the 2000 model. I'm thinking if it is a factory right hand drive, it is likely to be an export model or maybe a bastard export model with some mixed U.S. and Euro harnesses. Been my experience with export models, that the wiring colors are fairly universal, while the general layout and PDC configuration may be way off.

F17 in your last picture of the fuse box under the hood is the fuse that blows. I have had the entire engine side of the harness out, unwrapped and gone through tracing all of the wires and checking for problems. I have no burnt spots and am going to install a new TPS today and see if that changes the throttle issues. I understand you are trying to help and that is what I needed another brain to pick. Very frustrating. I will back probe the O2 wiring with it plugged in and the power on, not running. I am wondering what the ASD powers up after the first few seconds and maybe that is what is shorted. I know it effects alot of things and will shut the engine down if things get too weird. I have looked at a rt drive from Japan, wow what a mess. Nothing the same and all Japanese writing under the hood.

Last edited:

8Mud

NAXJA Forum User

- Location

- Central Germany

Maybe half a dozen reasons I can see for that fuse to blow. Usually the way I troubleshoot is to break the system down into pieces (in my mind) and eliminate as many variables as possible.

The fuse holder (female spade connector) is loose, generates heat and blows fuse. The wire from the fuse to the two relays (heater circuit) is shorted (or at the splice). I'm not sure if a bad splice could generate enough heat to blow the relay, it depends on how close the splice is to the fuse and how many amps the circuit draws. You have an internal short in one of the relays. One of the wires running from the relays to the O2 sensor heater is shorted (doubtful to be both). One of the O2 sensors has an internal short. What blows those fuses is heat, heat is usually a short, but can be resistance in a connector, a splice or even the wire itself under the insulation if some of the individual wires fatigue break and induce resistance at the weak spot (found one of those yesterday after two hours of looking).. Use your finger tips or an IR thermometer to look for hot spots.

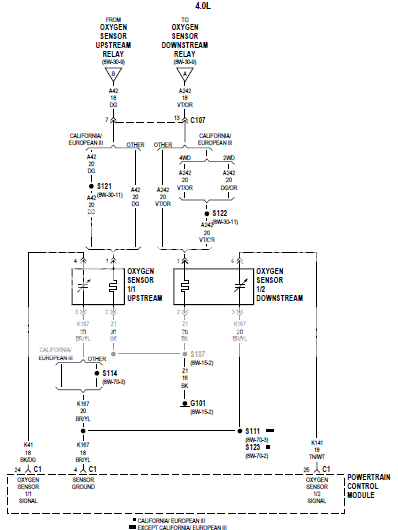

I was looking through the O2 circuit drawings for splices and other components that may share that fuse and didn't really see any, unless you have the four O2 sensor Euro 3/California model. A real issue with the new style circuit drawings is they are broken down into segments and don't really show an overview of the entire system (or even sub system), They may show a splice and you have to flip a dozen pages (or scroll) to figure out where the wire form the splice goes and if you find another spice on another page, it can get really confusing fast.

Break down the circuit (segregate) as much as possible and test each isolated section. Divide and conquer.

I usually isolate as many of the harness sections as practical and start working form one end of a circuit to the other with an ohm meter. Sometimes I start in the middle.

Visual inspection may help you out, an ohm meter is more likely to find the issue, either excessive resistance where there shouldn't be any or a shorted circuit.

I've seen loose connections like the female part of the fuse holder that had gotten loose and they can get really hot. Hot enough to turn the spade connector reddish, blue or even black, then melt the surrounding plastic. Discoloration right on the connector pins or spade connector metal is a tip off. Look for melted plastic. Use a good flashlight and get a closeup view of the connector contacts.

The fuse holder (female spade connector) is loose, generates heat and blows fuse. The wire from the fuse to the two relays (heater circuit) is shorted (or at the splice). I'm not sure if a bad splice could generate enough heat to blow the relay, it depends on how close the splice is to the fuse and how many amps the circuit draws. You have an internal short in one of the relays. One of the wires running from the relays to the O2 sensor heater is shorted (doubtful to be both). One of the O2 sensors has an internal short. What blows those fuses is heat, heat is usually a short, but can be resistance in a connector, a splice or even the wire itself under the insulation if some of the individual wires fatigue break and induce resistance at the weak spot (found one of those yesterday after two hours of looking).. Use your finger tips or an IR thermometer to look for hot spots.

I was looking through the O2 circuit drawings for splices and other components that may share that fuse and didn't really see any, unless you have the four O2 sensor Euro 3/California model. A real issue with the new style circuit drawings is they are broken down into segments and don't really show an overview of the entire system (or even sub system), They may show a splice and you have to flip a dozen pages (or scroll) to figure out where the wire form the splice goes and if you find another spice on another page, it can get really confusing fast.

Break down the circuit (segregate) as much as possible and test each isolated section. Divide and conquer.

I usually isolate as many of the harness sections as practical and start working form one end of a circuit to the other with an ohm meter. Sometimes I start in the middle.

Visual inspection may help you out, an ohm meter is more likely to find the issue, either excessive resistance where there shouldn't be any or a shorted circuit.

I've seen loose connections like the female part of the fuse holder that had gotten loose and they can get really hot. Hot enough to turn the spade connector reddish, blue or even black, then melt the surrounding plastic. Discoloration right on the connector pins or spade connector metal is a tip off. Look for melted plastic. Use a good flashlight and get a closeup view of the connector contacts.

Last edited:

8Mud- I have changed the new TPS out with another new TPS and that seems to have cured that problem. Now I only have the blown fuse issue. I have replaced both O2 sensors, I have the non-cal model, so only two, thank god. I will go back and check the sensors for shorts as well as the wiring with and without power after the key is in the on, not running position. I have not noticed any of the fuses being melted or burnt on the prongs and I have changed out all of the relays, but will go through them again. I am pretty good at trouble shooting when I have a good wiring diagram, but as you stated, this one is a mess. While employed at United Airlines, I won the top gun award twice for trouble shooting aircraft problems on the first try for the least cost.

My biggest thing I would like to know is what else does that circut share, I have heard issues with the back side of the power dist having corrosion, that will be another thing for me to look at. Again, thank you for your help and keep it coming.

My biggest thing I would like to know is what else does that circut share, I have heard issues with the back side of the power dist having corrosion, that will be another thing for me to look at. Again, thank you for your help and keep it coming.

8Mud

NAXJA Forum User

- Location

- Central Germany

You've likely more talent than I do, my main claim to fame is I never give up. The dogmatic approach usually works out for me. If I know for sure there is a problem in the system I'll eventually find it. I've eventually found some really strange faults over the years. If it were easy it would likely already be fixed.

I'll roll it around in the old brain and see if I can't come up with anymore new possibilities.

Did you try pulling one relay at a time and seeing if the fuse still blew? It is likely to run (though poorly) with one or even no O2 sensors. If you can narrow it down to the front or rear circuit you've won half the battle.

Your finger tips will sometimes lead you down the right path, follow the heat.

As an absolute last resort, put a 50 amp fuse in there and look for smoke. Don't do that I'm kidding. Harness fires aren't fun.

A rare occurrence is the wire under the insulation being almost broken with most of the copper threads broken and only a few making contact, acts like a big resistor and generates heat. It would likely be near the fuse or the wire would eventually burn in two farther downstream. The wires in any car sometimes get a vibration workout and over the years the copper threads under the insulation fatigue and break. A longshot, but I have seen it before, more than a few times.

The way the contact strips are set up in many PDC busses (seen it in Chevy) is it is a pressure contact and not actually soldered or screwed down. I don't know specifically about your 2000. But I've seen it before, the little pressure clip that forces contact with the bus in the PDC overheats once, due to a shorted component or a shorted wire farther downstream, and the pressure contact for the fuse on the bus relaxes and makes a poor contact and generates heat on the upstream side of the fuse. Kind of a reach, but we seem to be running out of possibilities. One way to check this out would be to use two male/female combination spade connectors and raise the fuse up out of the holder and then you can feel which side gets hot first. Just an idea. Be careful you don't blister your finger tip.

I'll roll it around in the old brain and see if I can't come up with anymore new possibilities.

Did you try pulling one relay at a time and seeing if the fuse still blew? It is likely to run (though poorly) with one or even no O2 sensors. If you can narrow it down to the front or rear circuit you've won half the battle.

Your finger tips will sometimes lead you down the right path, follow the heat.

As an absolute last resort, put a 50 amp fuse in there and look for smoke. Don't do that I'm kidding. Harness fires aren't fun.

A rare occurrence is the wire under the insulation being almost broken with most of the copper threads broken and only a few making contact, acts like a big resistor and generates heat. It would likely be near the fuse or the wire would eventually burn in two farther downstream. The wires in any car sometimes get a vibration workout and over the years the copper threads under the insulation fatigue and break. A longshot, but I have seen it before, more than a few times.

The way the contact strips are set up in many PDC busses (seen it in Chevy) is it is a pressure contact and not actually soldered or screwed down. I don't know specifically about your 2000. But I've seen it before, the little pressure clip that forces contact with the bus in the PDC overheats once, due to a shorted component or a shorted wire farther downstream, and the pressure contact for the fuse on the bus relaxes and makes a poor contact and generates heat on the upstream side of the fuse. Kind of a reach, but we seem to be running out of possibilities. One way to check this out would be to use two male/female combination spade connectors and raise the fuse up out of the holder and then you can feel which side gets hot first. Just an idea. Be careful you don't blister your finger tip.

- Location

- Antioch, CA

8Mud- I have changed the new TPS out with another new TPS and that seems to have cured that problem. Now I only have the blown fuse issue. I have replaced both O2 sensors, I have the non-cal model, so only two, thank god. I will go back and check the sensors for shorts as well as the wiring with and without power after the key is in the on, not running position. I have not noticed any of the fuses being melted or burnt on the prongs and I have changed out all of the relays, but will go through them again. I am pretty good at trouble shooting when I have a good wiring diagram, but as you stated, this one is a mess. While employed at United Airlines, I won the top gun award twice for trouble shooting aircraft problems on the first try for the least cost.

My biggest thing I would like to know is what else does that circut share, I have heard issues with the back side of the power dist having corrosion, that will be another thing for me to look at. Again, thank you for your help and keep it coming.

The diagrams that 8mud has posted should get you to where you can figure it out. The F17 fuse powers only the 2 o2 sensor relays and heaters. Seems like you have been given the information but maybe you are thinking it over too hard.

If it were me I would start with this:

1 - Disconnect both the oxygen sensors and see if the fuse still blows. Ok I know you have done this and it still blows, so continue on.

2 - Remove the 2 oxygen sensor relays from the Power distribution center (PDC). Does the fuse still blow? Yes, the short is in the PDC. No, the short is somewhere else. If the short isin the PDC then it should be easy enough to find it, disconnect the battery and disassemble the PDC and look for the shorted wire. If the fuse doesn't blow then continue on to #3.

3 - With the o2 relays removed and both of the oxygen sensors disconnected, use an ohm meter to check for a short to ground in the relay output circuits. Use the wiring diagram above and find the A42, and A242 circuits, these are the relay output circuits. If there is any resistence when checking those circuits to ground then this is the circuit that is shorted to ground.

4 - Repair the short. Either tear the harness apart again, or just run an entirely new wire from the PDC to the sensor.

- Location

- Antioch, CA

Oh and just to put this out there, corrosion and high resistence in a circuit normally will cause lower amperage in a circuit and will NOT cause a fuse to blow.

Bryan C- Thanks for the other ideas, and you are correct, this is making me nuts and I have looked at it way too hard. I have pulled the entire harness out 3 times and shot every wire, all new sensors and it may come down to the PDC having been the issue all along.

8Mud- Looks like the PDC will be my next stop. I did, even against my best judgment, place a wire across the fuse and it tripped the shutdown relay instantly shutting the system down, so no harm done, as it was instant. I was hoping at that point to burn up whatever was causing the problem or set the jeep on fire, getting frustarted, but never giving up. I have seen wires get work hardened and break, happened to me once on a Boeing 727 for the autopilot system in the over head cockpit area, but I had a scope that helped allot. Thanks again for the added help, its hurting my brain. I am working on 3 Jeeps at once.

8Mud- Looks like the PDC will be my next stop. I did, even against my best judgment, place a wire across the fuse and it tripped the shutdown relay instantly shutting the system down, so no harm done, as it was instant. I was hoping at that point to burn up whatever was causing the problem or set the jeep on fire, getting frustarted, but never giving up. I have seen wires get work hardened and break, happened to me once on a Boeing 727 for the autopilot system in the over head cockpit area, but I had a scope that helped allot. Thanks again for the added help, its hurting my brain. I am working on 3 Jeeps at once.

Fixed Finally. Thank you 8Mud and Bryan C. I went back and started again like you both mentioned because I was making too much of it. I pulled the PDC apart and started tracing from there. No major issues as far as corrosion, so I pulled both relays and started tracing and checking resistances. I disconnected both O2 sensors and took the wiring harness into pieces, disconnecting C107 to the engine harness. PDC to C107 all checked good. I checked the other half from each PCM plug to both O2's. Having thought I found an issue I cut one wire and put in the fwd O2 relay. Started it and no blown fuse. Put in the rear relay and still no blown fuse while running. Somewhere down the line the power wire for the rear O2 sensor had been spliced into the sensor ground for all sensors. Hooking it to the rear O2 power only fixed it. I found it by checking what I did know and then checking things that should not be. I hav a wire making contact to two points instead of one. Thanks again, now to fix the cooling issues and I am set. I think a new thicker radiator is in store. I have 3 electric fans and it still runs too hot while deliverying mail.

Similar threads

- Replies

- 1

- Views

- 1K