I am getting ready to swap the motor out of my 94. Before I do so i'd like to get my motor on a stand to replace the gaskets and clean it up a bit. I did a search but found a few conflicting answers on the bolts needed to bolt the engine to the stand.

If it matters the motor going in is out of a 96 xj 4.0. The one coming out is a 94 4.0

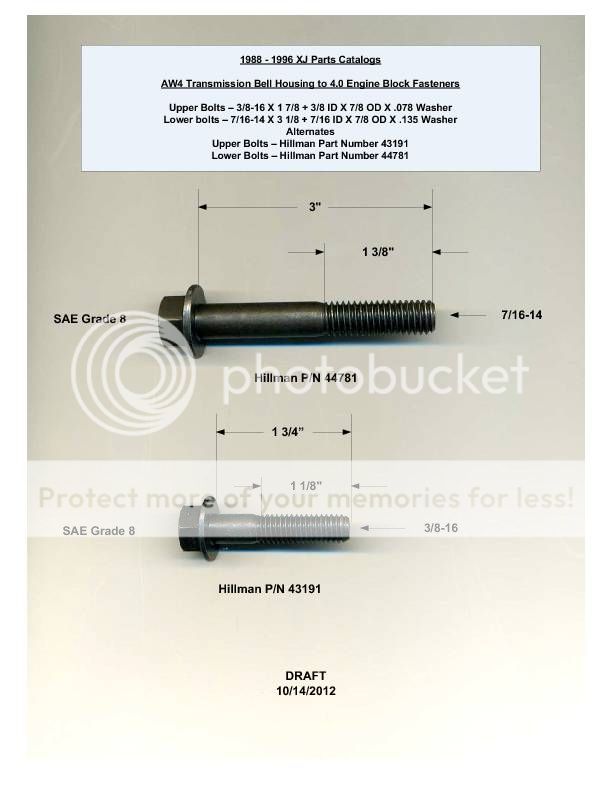

The bolt info that i found is:

top bolts: 3/8"x16

lower bolts: 7/16-14

Also saw lower: m10x1.5

Thanks

If it matters the motor going in is out of a 96 xj 4.0. The one coming out is a 94 4.0

The bolt info that i found is:

top bolts: 3/8"x16

lower bolts: 7/16-14

Also saw lower: m10x1.5

Thanks