bugout

NAXJA Forum User

DYE electrical grease. Should this be used in every electrical contact connection??? Are there any situations where I DO NOT want to use it? Getting ready to replace a couple of snesors and lights.

Use it VERY sparingly. Another good example is to use a little dab in spark plug boots to make the boot easier to remove later. Keep in mind it is non-conductive, so the idea is to keep dirt and corrosion out of connections and to lube the rubber or plastic connectors.

So NOT when splicing wires under the hood like underneath heat shrink crimped connection or electrical tape???

(Never ordered from DelCity, but they had several helpful videos explaining the basics of various types of connections/terminals, as well as a huge assortment of parts.)

@ Bryan, Thanks!

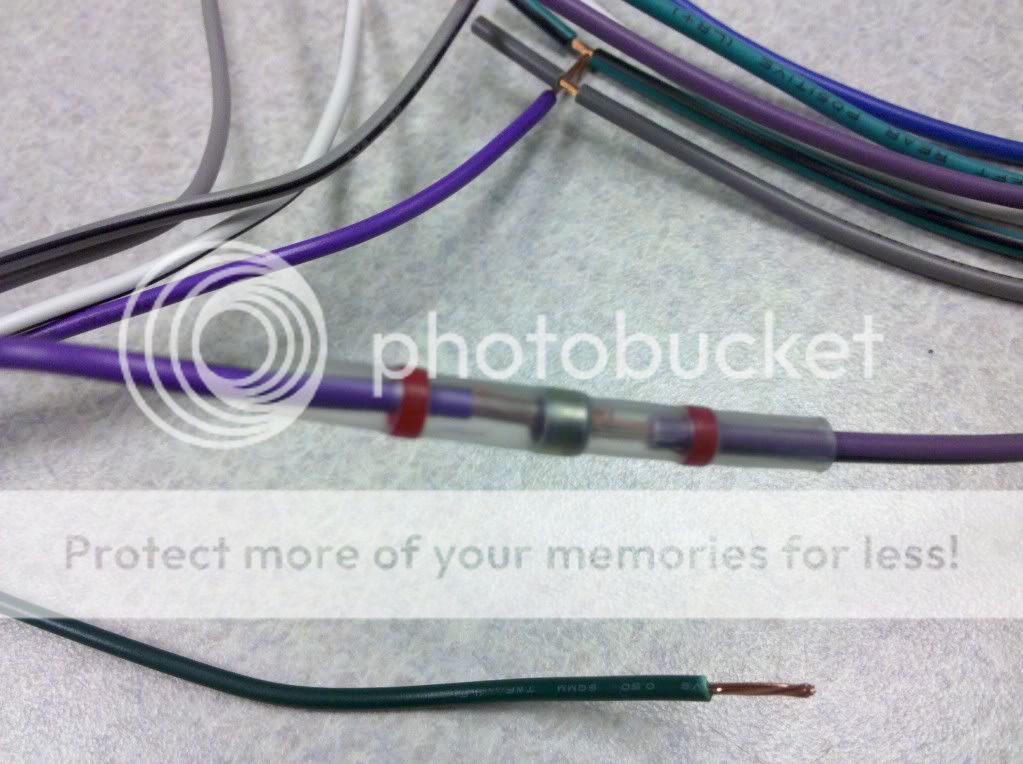

@USMCGunrock, how exactly to the solder/heatshrink butt connectors work, I've never seen them before?

DYE electrical grease. Should this be used in every electrical contact connection??? Are there any situations where I DO NOT want to use it? Getting ready to replace a couple of snesors and lights.