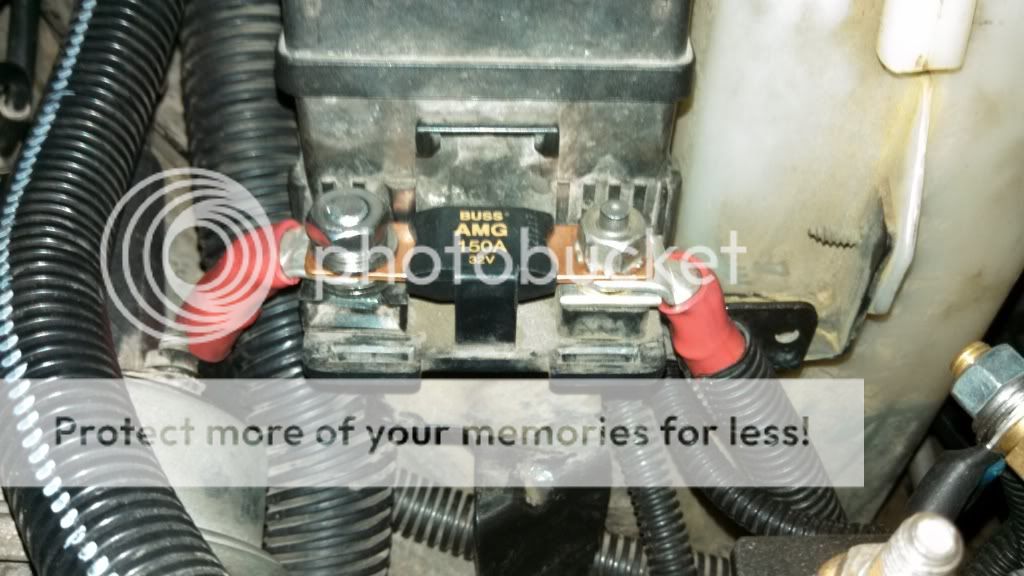

Soooooo did this before on a 98 and it was pretty simple. This one not so much. Beefed up the grounds from the battery and was rewiring the power (positive cable) to the control unit (thing with the fuses and relays next to the battery) without a problem. I cut the bracket that connects to the two bolts and put it on the new battery cable.

Now I ran into an issue. Was tracing the main wire from the alternator and it doesnt go to the battery. It heads up into the wire loam. I pulled damn near everything out that I could and cant trace this wire. Can I just cut it and add an inline fuse going strait from the alternator to the battery?

Now I ran into an issue. Was tracing the main wire from the alternator and it doesnt go to the battery. It heads up into the wire loam. I pulled damn near everything out that I could and cant trace this wire. Can I just cut it and add an inline fuse going strait from the alternator to the battery?