Bronco

NAXJA Forum User

- Location

- Swansboro, CA

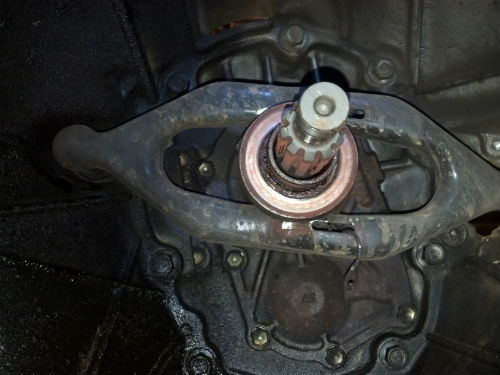

I am in the process of dropping my tranny to do the clutch. I can’t figure out how to get the shifter off and I got to wondering if I even need to? Also what is the best way to get the inner boot off some of the screws are not very accessible.

Anyway I guess I need any tips for how to get the shifter area apart to drop the trans.

We are talking about a 98 with an AX-15

Thanks

Anyway I guess I need any tips for how to get the shifter area apart to drop the trans.

We are talking about a 98 with an AX-15

Thanks