bcmaxx

NAXJA Forum User

- Location

- The West Kootenays,B.C. Canada

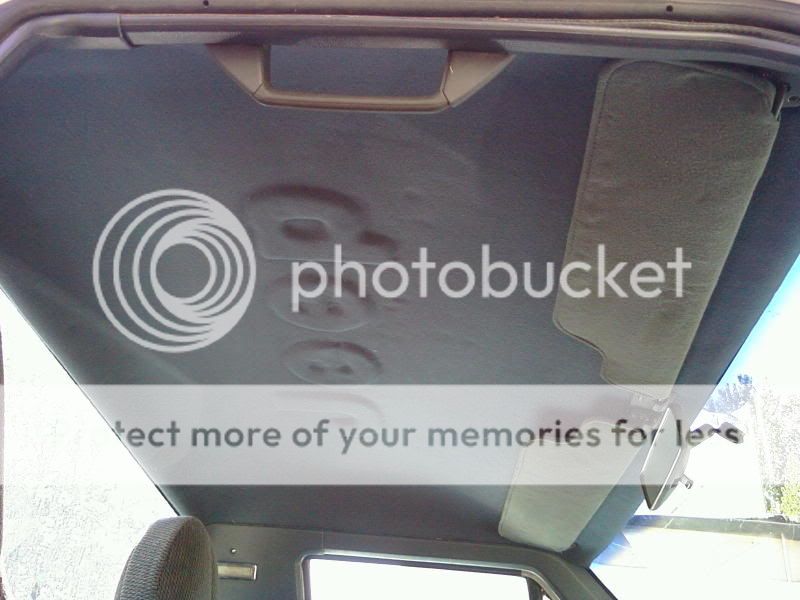

Well I decided to pull my sagging,broken torn headliner out in pieces to repair separated roof ribs and replace my factory sunroof. I had no clue it was fiberglass and I'd be itching for two days. Anyways I'm going to dynamat it then not sure what to do. I'd be more inclined to leave it if that stuff didn't have logos all over it .but I may anyways. I have the old headliner to make a template of and maybe cut a new one out of some different material? Anyone try any other materials? :dunno: