cypertj

NAXJA Forum User

- Location

- Canton, Texas

I hate for this to be my first post, but I have a quick question. I WILL come back and introduce myself later. I promise!

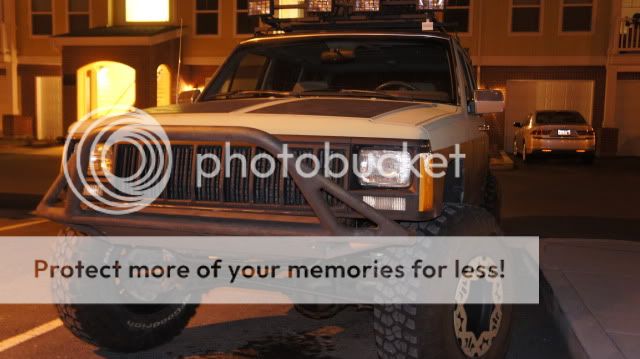

I have a 93 XJ, 4x4 4.0, I recently aquired this rig from my brother and it needs a front axle. I would like to upgrade and run 35s so I know I need at least d44s. I want this to be a tough trail rig, probably a trailer queen. Right now I'm thinking about a 6" long arm lift with coil over conversion in the rear. I will probably keep the stock 4.0 until it dies. It's gonna be a long road but well worth it in the end.

I have found a guy with a 78 bronco he's parting out and I can get both axles for $200. i understand these have cast wedges. Will these be a big problem and should I pass on these or would these axles make a good swap with a little blood, sweat, and tears.

Thanks Guys

I have a 93 XJ, 4x4 4.0, I recently aquired this rig from my brother and it needs a front axle. I would like to upgrade and run 35s so I know I need at least d44s. I want this to be a tough trail rig, probably a trailer queen. Right now I'm thinking about a 6" long arm lift with coil over conversion in the rear. I will probably keep the stock 4.0 until it dies. It's gonna be a long road but well worth it in the end.

I have found a guy with a 78 bronco he's parting out and I can get both axles for $200. i understand these have cast wedges. Will these be a big problem and should I pass on these or would these axles make a good swap with a little blood, sweat, and tears.

Thanks Guys