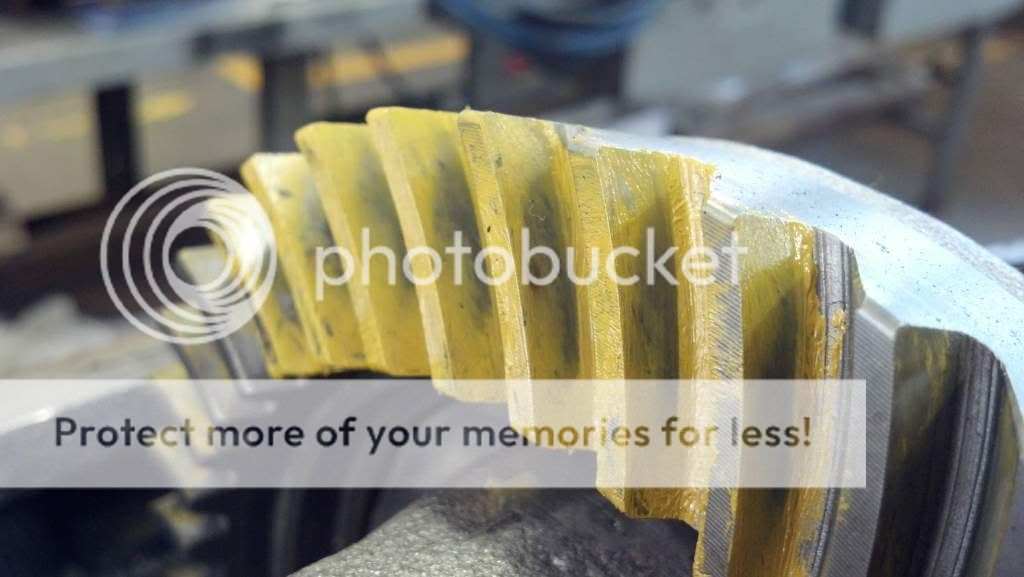

Started setting up the 4.56 gears for my dana 30 today and ran my first pattern. My backlash is at 18 thousandths and according to the pattern chart i need to add more shim to my pinion.

Am i right in thinking that when i add the shim to my pinion it should decrease my backlash and bring it closer to spec? And how much should i add to my pinion shim for my next attempt?

Drive side

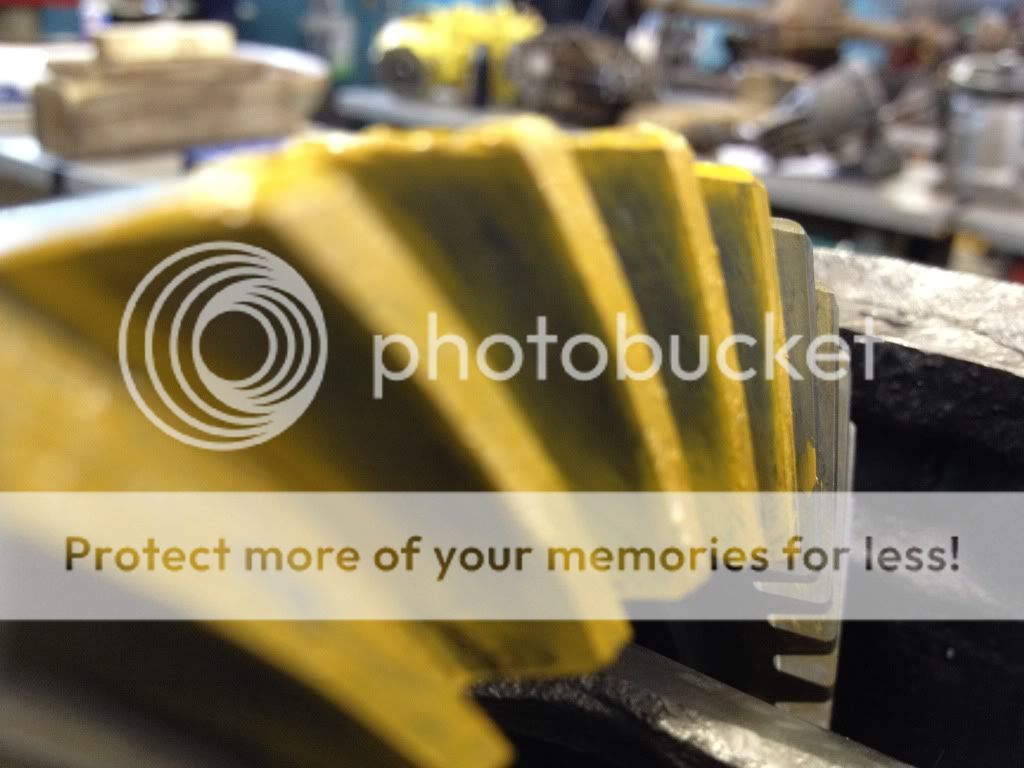

Coast Side

Am i right in thinking that when i add the shim to my pinion it should decrease my backlash and bring it closer to spec? And how much should i add to my pinion shim for my next attempt?

Drive side

Coast Side