Dr. Jeckel

NAXJA Forum User

- Location

- Amarillo, Texas

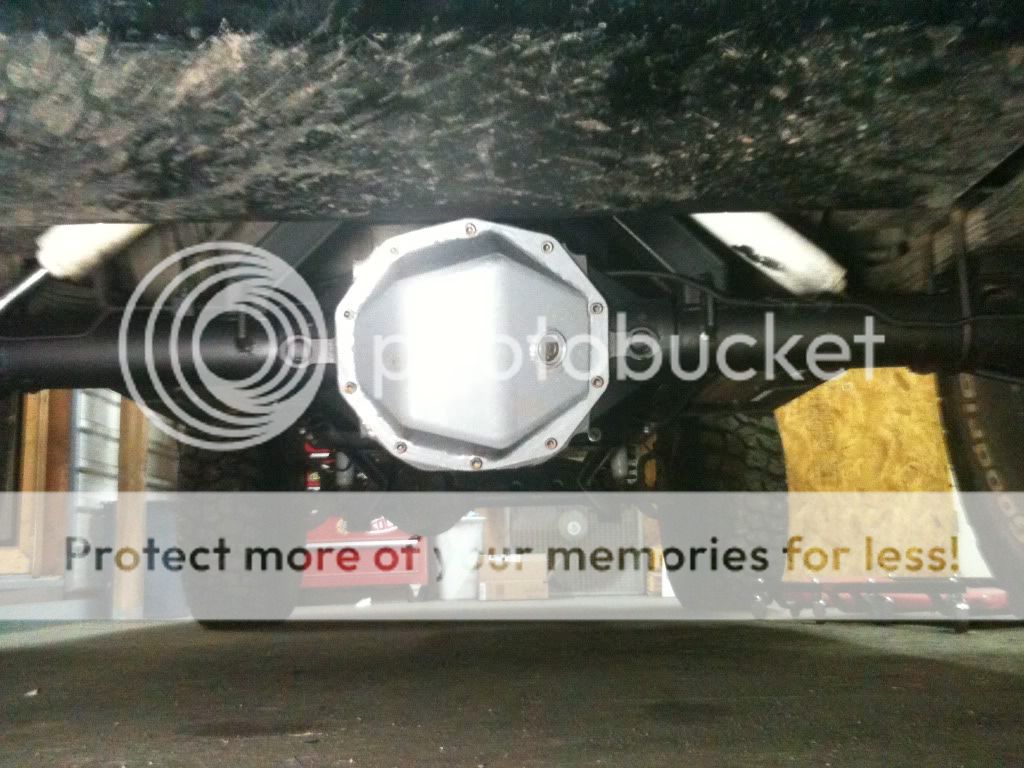

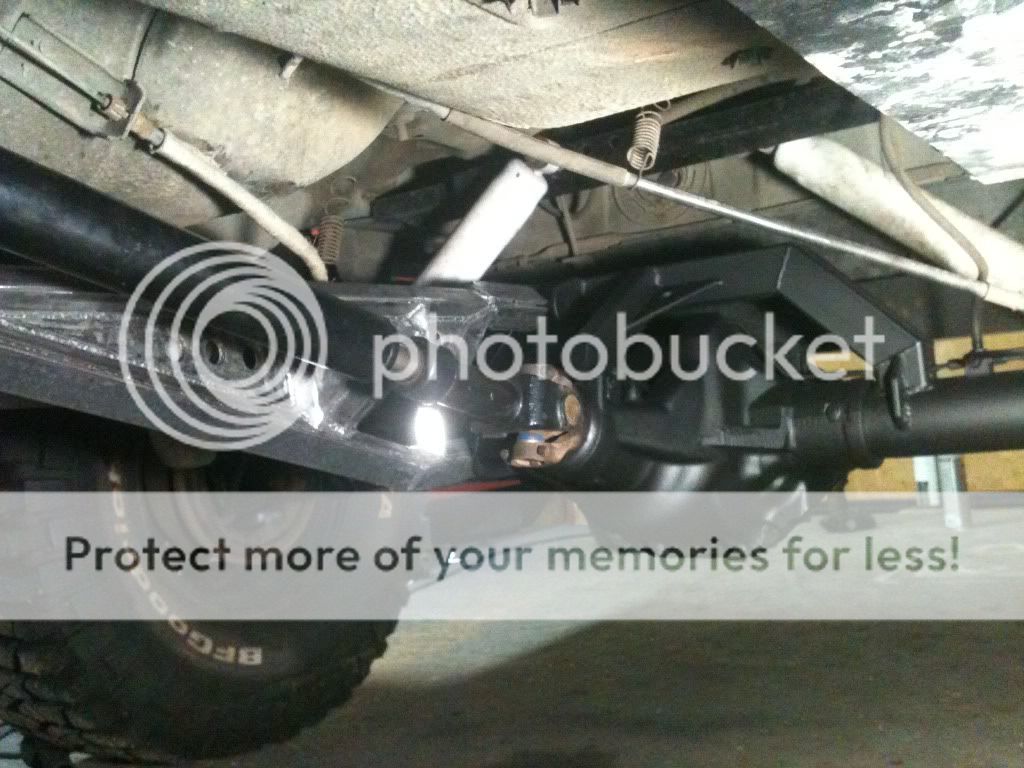

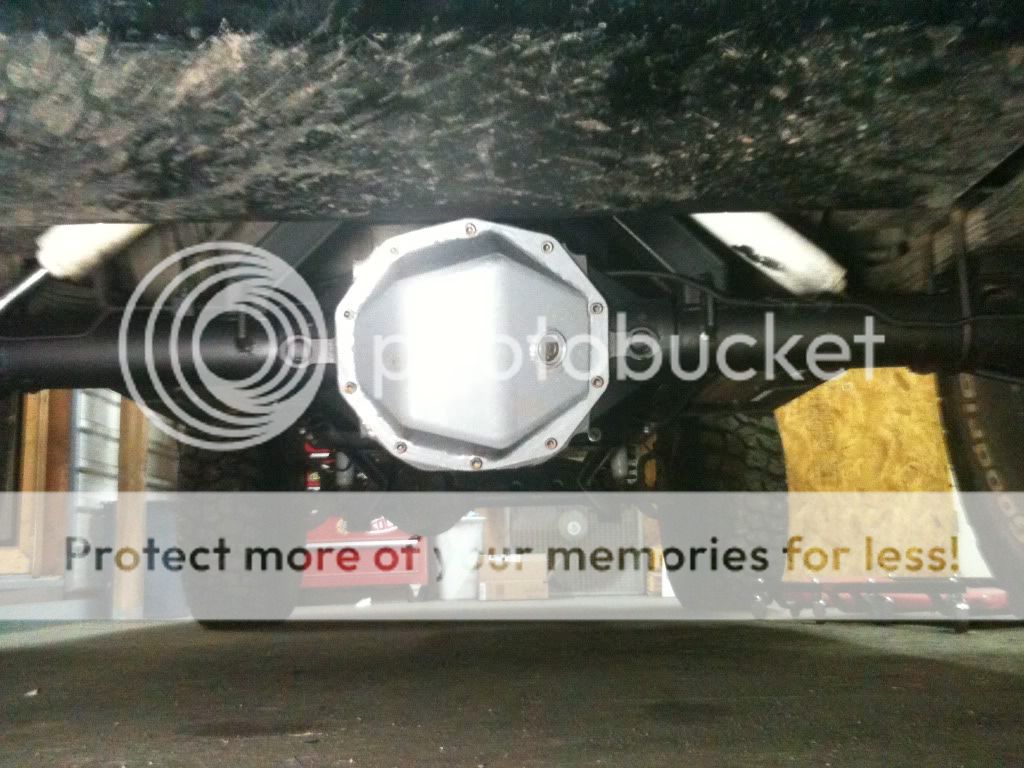

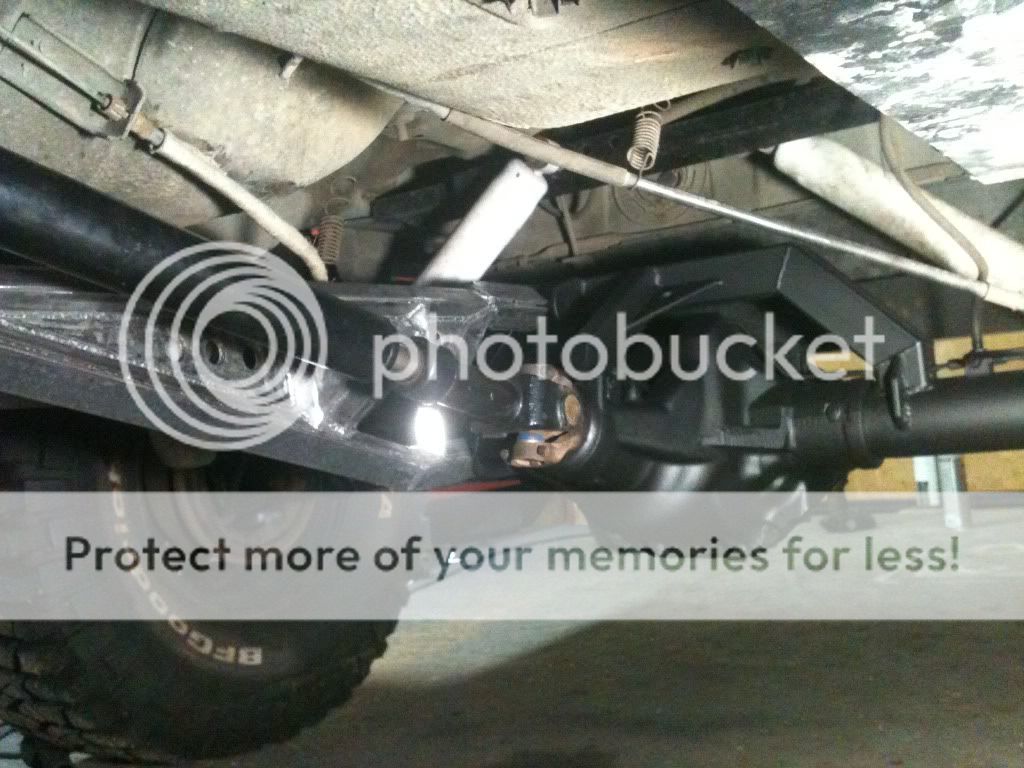

Well, I finally finished my antiwrap bar today. I started the bar about 2 months ago and finally got around to doing the rest this week. I also decided to make a belly skid to go between the trans/control arm crossmember and the antiwrap crossmember to replace the TC skid plate I had on it.

The antiwrap bar follows the angle of the driveshaft and also functions as protection for the rear drive shaft yoke.

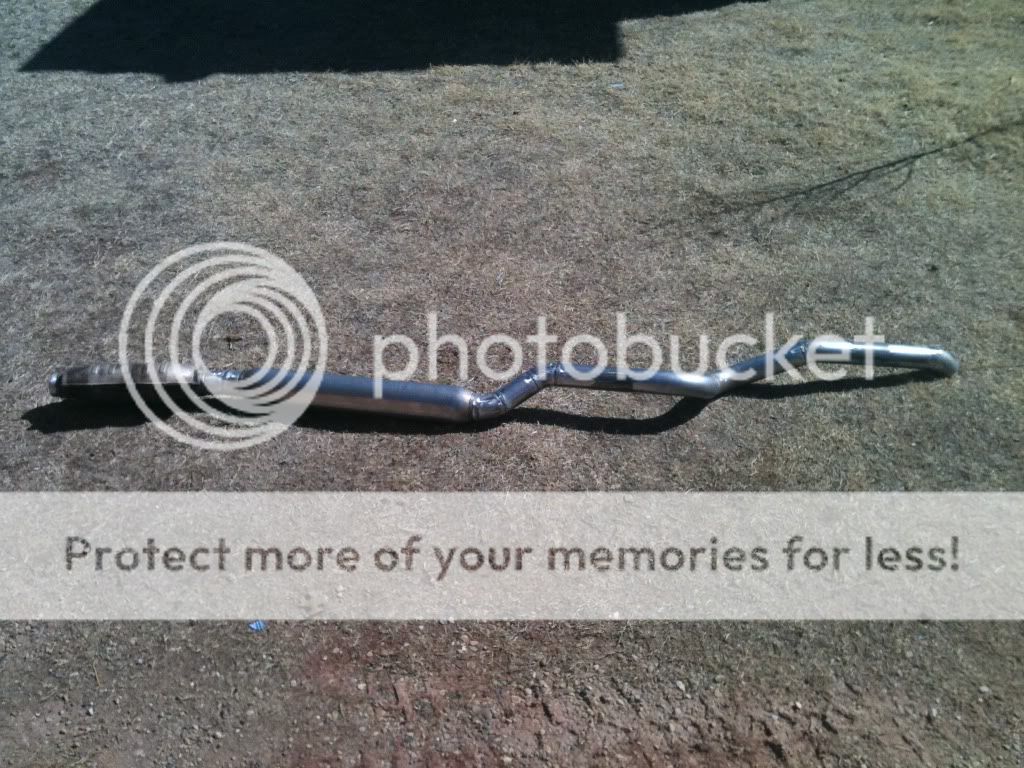

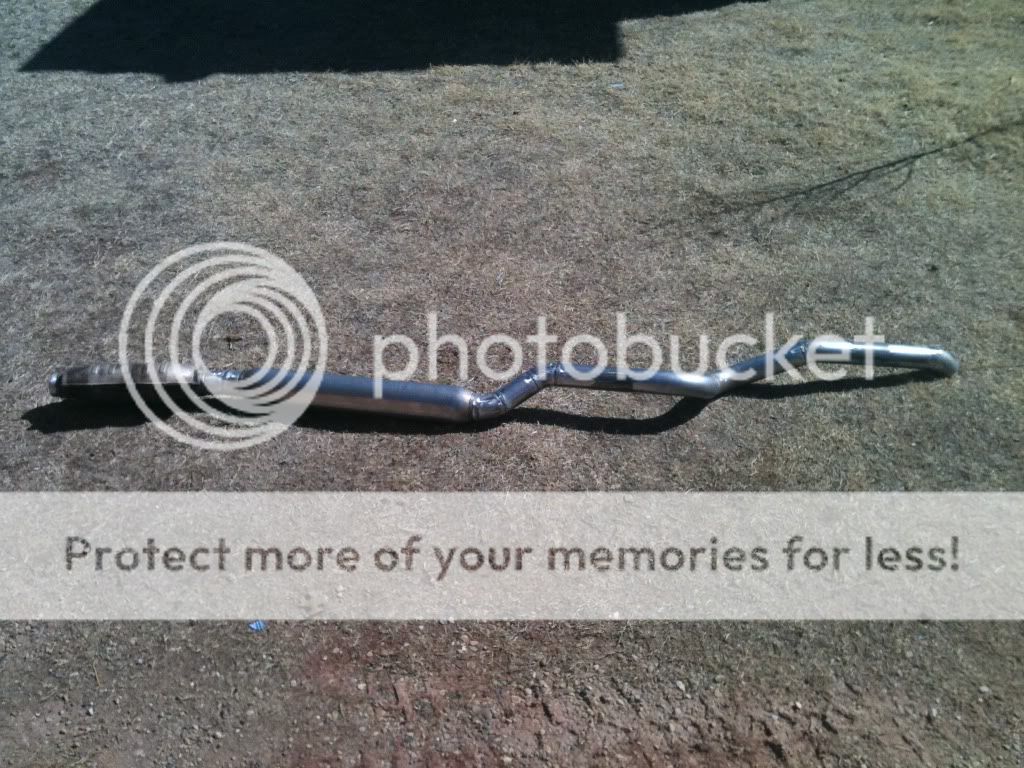

I also had to remake the exhaust from the cat back to tuck it up and make room for everything.

All in all I am pleased with how things turned out and it should function well.

Some specs on the pieces:

3/16" plate for the skid plate with 3/4" .120 wall angle cross support

2" .120 wall tube for the truss and antiwrap crossmember

1" .120 wall tube with 1.25" .25 wall angle welded to the bottom of the antiwrap bar

Gusset plates for the truss and antiwrap bar are .25" plate

Bushings are 2" wide and the heim is a 3/4" piece with 9/16" bolts used (from ruffstuff)

The shackle is made from 3/16" plate

Here are some pictures, I used my phone so they're not the best but should show things well enough.

The antiwrap bar follows the angle of the driveshaft and also functions as protection for the rear drive shaft yoke.

I also had to remake the exhaust from the cat back to tuck it up and make room for everything.

All in all I am pleased with how things turned out and it should function well.

Some specs on the pieces:

3/16" plate for the skid plate with 3/4" .120 wall angle cross support

2" .120 wall tube for the truss and antiwrap crossmember

1" .120 wall tube with 1.25" .25 wall angle welded to the bottom of the antiwrap bar

Gusset plates for the truss and antiwrap bar are .25" plate

Bushings are 2" wide and the heim is a 3/4" piece with 9/16" bolts used (from ruffstuff)

The shackle is made from 3/16" plate

Here are some pictures, I used my phone so they're not the best but should show things well enough.