MARCH 2012:

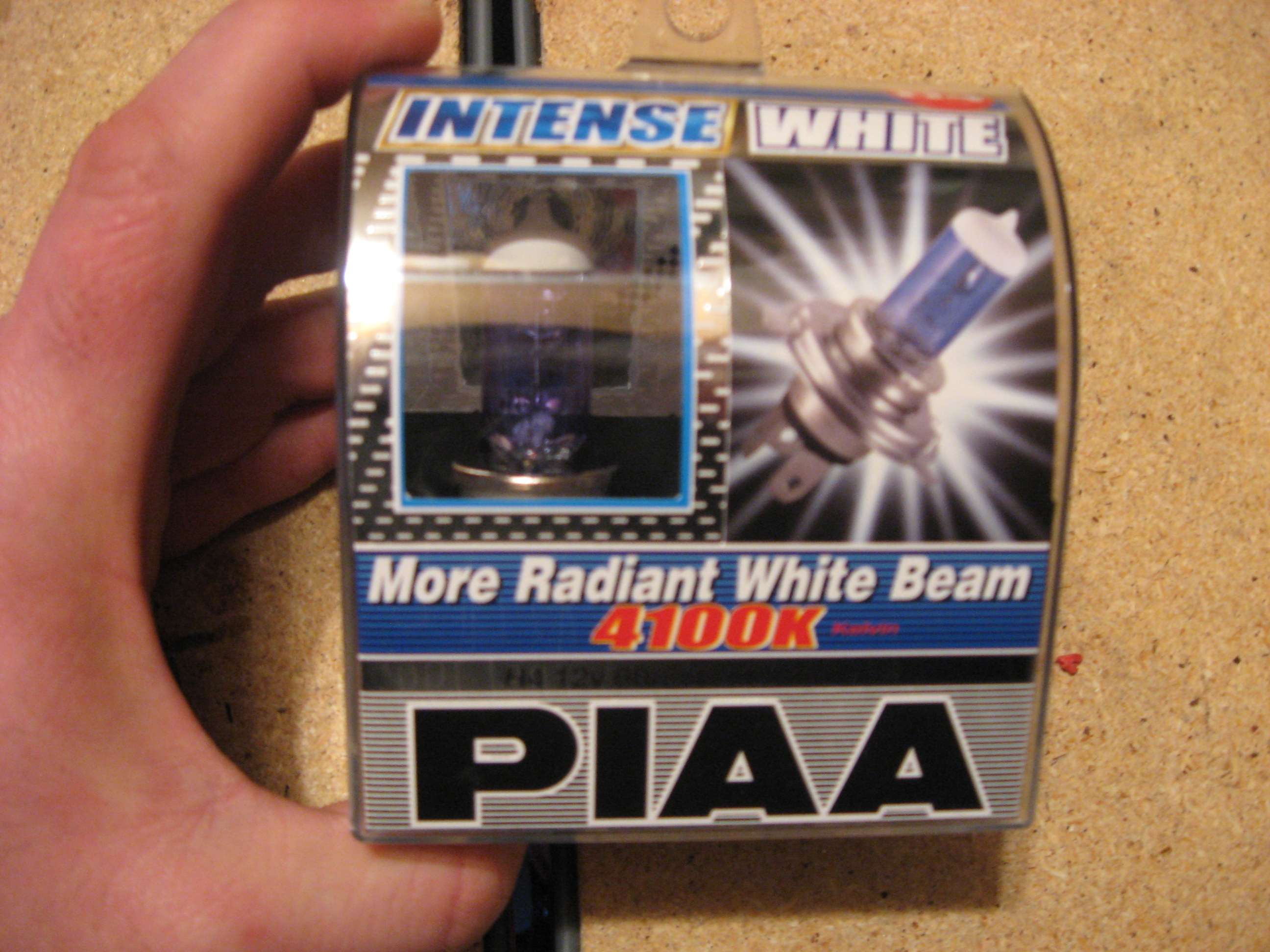

Next up was to make sure some of the mechanical was all in order. A Full Tune-up was done. I had been keeping real good track of the MPG's and i was averaging a solid 15-16 mpg. The best i had was a touch over 18. I know these things arent the most fuel economic vehicle out there, but i know there was 2-4 mpg i could squeek out of it. I also knew that my down stream (after the cat) O2 sensor was bad thanks to a trip to the mechanics shop for a full "used vehicle inspection." So after a trip down to the parts store here's what I decided to do, plugs, cap, rotor, O2 sensor, and a new high flow air filter.

I decided to do a modification to my stock air box, as I didnt want to fork out the bucks for a full intake system that gives you the protection from both heat, and water. Keeping the stock air box and dropping in a good high flow, gives about the same results as a aftermarket system.

Here's how that all went:

First you remove the blow by tube, and the intake tube form the air box, removing the air filter, leaves you this:

There's two mounts that hold this in place, the one towards the rear is on a stud, while the one towards the front bolts thru the box to a welded nut on the body. I PB blasted them before hand, and let it soak for about 30mins before proceeding. Of course in true Jeep fashion, the front bolt broke off on me:

No worries, on to the next steps..... The factory air box has a small, flanged intake port. This restricts the airflow into the intake, and can easily be modified. Now this CAN be done IN the vehicle, but it is far easier taking it out, and i'll show you why later.

This shows the factory opening in the air box. (i had aleady made most of the cuts, in this pic):

After the cutting is done: (note: all i used was a jig saw to make the cuts, a saw blade, hot knife, or sawzall could be used to do this as well.)

This shows after the cut, the difference between the stock opening, and the modified one as you can see, this will allow a much greater mass of air to be drawn in, while still keeping the filter out of the elements:

Next I de-burred the edges with a file, and smoothed all the cuts, rounding them off, leaving no restrictions for airflow.

After modifications are done, reinstall the air box. With one of my bolts broken, the only factory mounting point was the rear stud. There is however (on my 99) a small hole (aprox 1/8" in the bottom towards the front,) which I used as a guide to drill a pilot hole in the body for a new screw to secure the front half of the air box. You'll see the shiny #10 x 1/2" steel screw in this pic that was used.

Only thing left to do is drop in the new air filter and button it all up.

Next it was on to the tune up, the plugs were definitely shot:

And the cap was toast too. Note the build up on the contact points, obviously this would prevent good electrical conductivity, and create a weak spark. Now the engine wasn't running rough before, but it certainly lacked pep, and the mpg's were showing sign of ineffeciency.

Now I know i could have just scraped the contacts, and sanded the rotor down to shiny metal and called it good. But to me thats just a band aid.

Next was on to the O2 sensor, let first say that was a PITA to get out. It was rusty, and might as well have been welded in. It was probably the OEM unit, and had never been replaced. I soaked it with PB Blaster several times for at least 1.5 hours before hand. Finally came out and here's the comparison between the old (left) and the new (right)

The new sensor had a much longer wire harness, and after installed it was obvious that there was potential for failure, as the harness was lying on the drive line:

So using the factory plastic connector shield (black plastic assembly in photo) I noticed a spot where there was room for a zip-tie to be placed tying up the harness out of the way.

Note the small rectangular opening towards the bottom of the plastic housing at the bottom of the pic:

(also, this housing must be removed in order to disconnect the old sensor and plug in the new one, only one bolt holds it in place, and strangely enough, came out quite easily)

Thats pretty much it. I had in the beginning removed the positive battery terminal, and after a few minutes, held it ground briefly to discharge the computer's memory. This caused some rough idling and acceleration upon restart after the job was completed, but smoothed out after a full heat cycle, and a 30 min drive. Even after that, I could tell the computer was still "learning" and will eventually smooth out completely with more driving.

Towards the end of the drive it was very clear that the engine was running ALOT better, and acceleration had improved as well.

Hope this shows you how an afternoon, and a few things form the parts store can not only improve efficiency, but also give you a little increase in performance.

)

)

.

.