I have an AX15/231/D35 combo on about 4" of lift. With that combo, the slip yoke was pretty far out of the case; I think the shop said there was about 1.5" of engagement, and that it was okay.

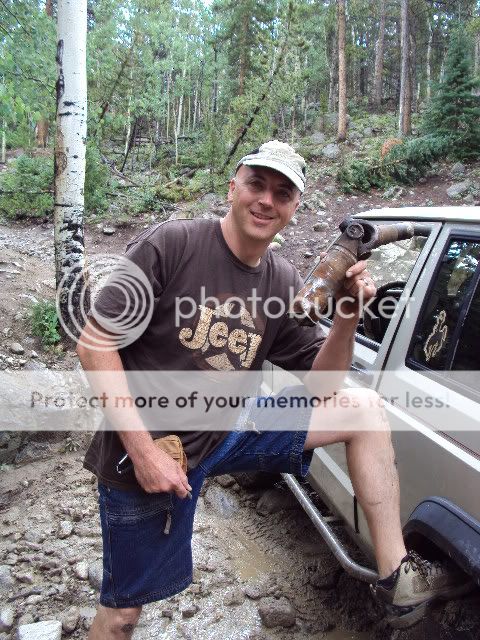

I just swapped in an 8.25 axle, thinking the longer snout would push the yoke back into a safer range. It looks like the snout is way longer, as the yoke seems like it is fully pushed into the case while sitting level at rest; to my eyes, it looks like only 3/8 of the shaft is exposed. I'm thinking the driveshaft is way too long, and will smash the tcase if I bottom out the suspension.

I know a SYE is the ideal solution, but I currently can't afford it. I want to just grab a shorter dshaft from the junkyard and run it for a while. My question is, how far out should the yoke be from the case? Would it be 1"? 2"? xx"? I figure I'll be close enough to find a correspondingly shorter driveshaft and swap it in..

Actually, how long is the stock slip yoke? Can I just divide that length in 2, and subtract that from my current driveshaft length?

I just swapped in an 8.25 axle, thinking the longer snout would push the yoke back into a safer range. It looks like the snout is way longer, as the yoke seems like it is fully pushed into the case while sitting level at rest; to my eyes, it looks like only 3/8 of the shaft is exposed. I'm thinking the driveshaft is way too long, and will smash the tcase if I bottom out the suspension.

I know a SYE is the ideal solution, but I currently can't afford it. I want to just grab a shorter dshaft from the junkyard and run it for a while. My question is, how far out should the yoke be from the case? Would it be 1"? 2"? xx"? I figure I'll be close enough to find a correspondingly shorter driveshaft and swap it in..

Actually, how long is the stock slip yoke? Can I just divide that length in 2, and subtract that from my current driveshaft length?