sledneck

NAXJA Forum User

- Location

- Durango, Co

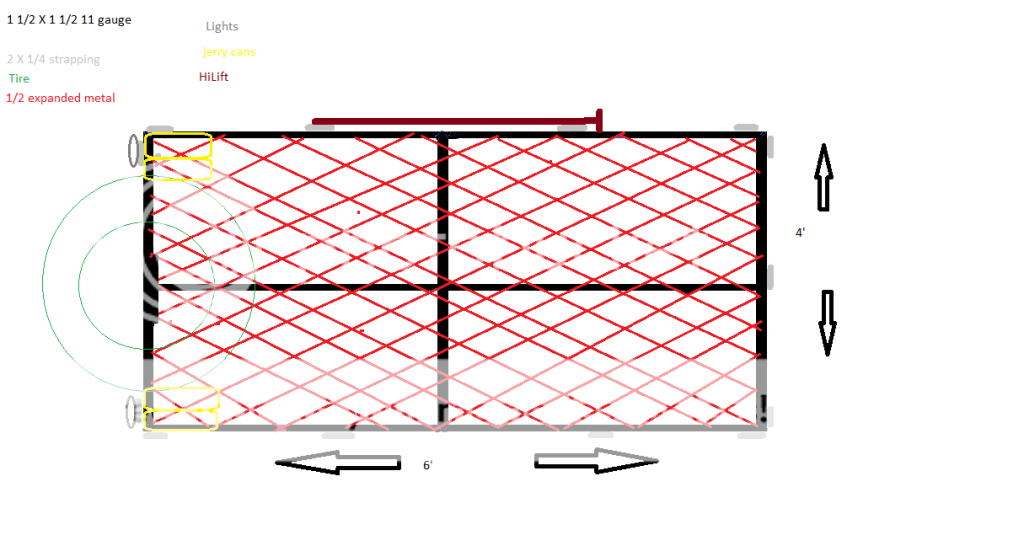

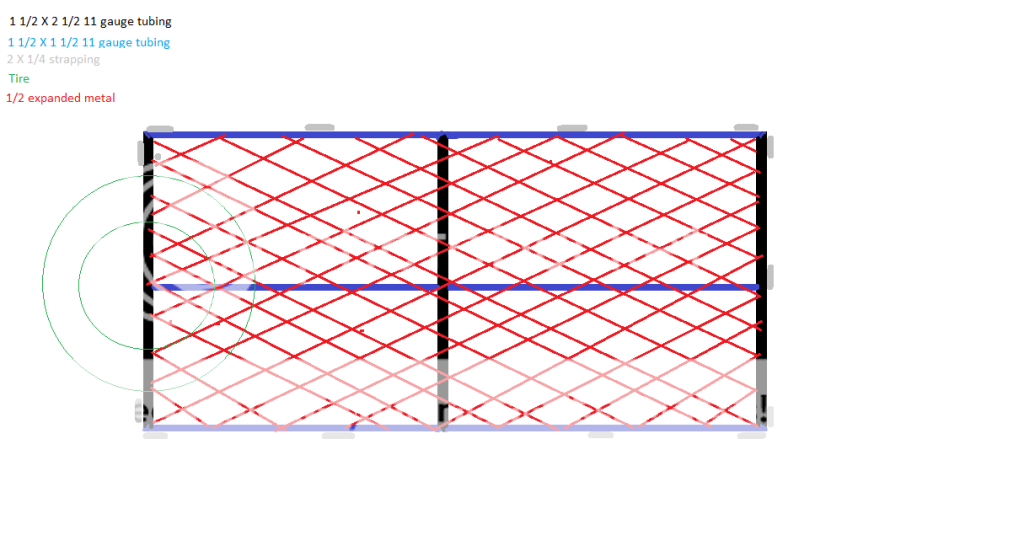

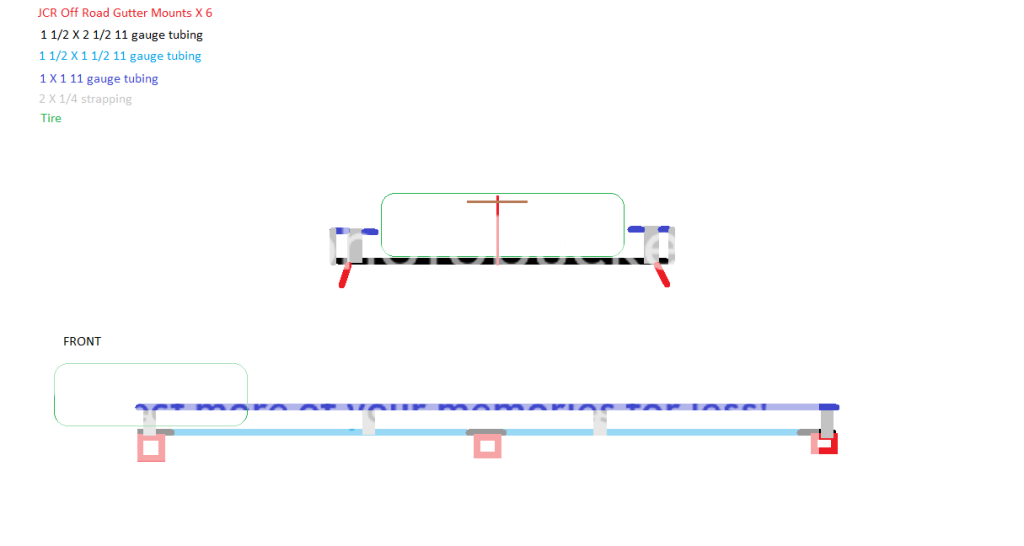

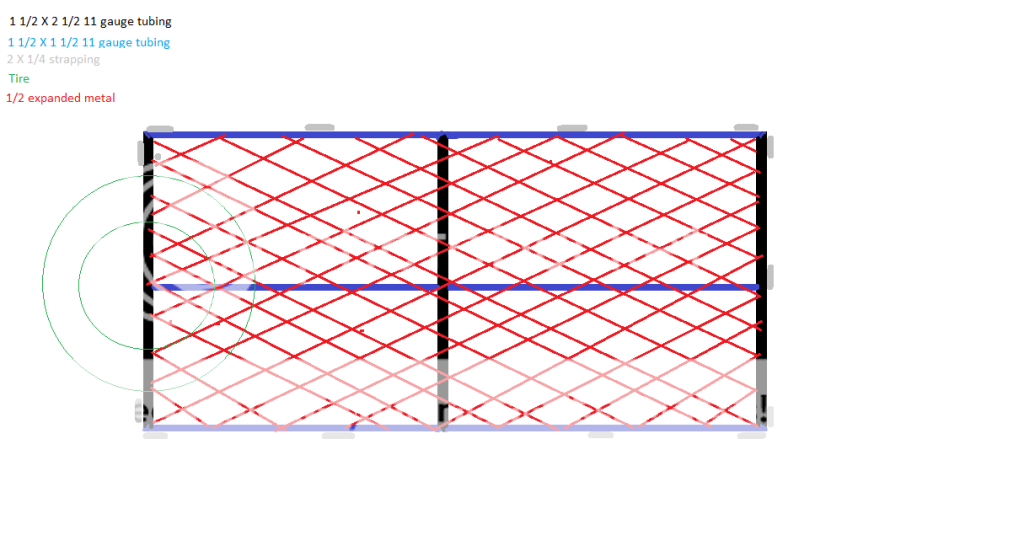

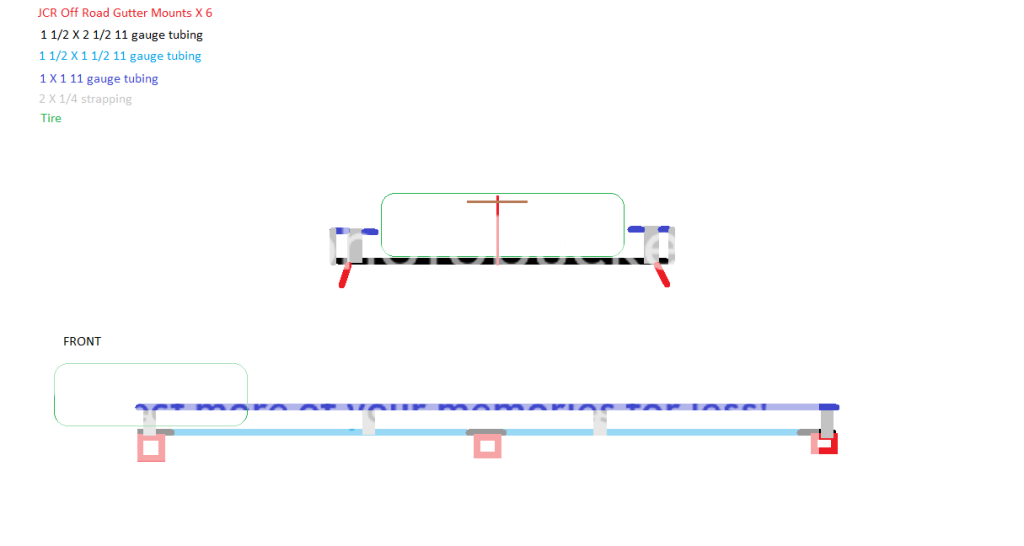

I planning on building a roof rack and made some very rough designs. its going to be six foot long and four foot wide and probably six inches tall on the side rails. Im gonna put the tire on it planning on running a long bolt through the main supports on the front and welding it in place. Going to put the hi lift on one side too and only have a rough idea how I'm gonna do that. I price the material and its gonna be about $200 for the materials plus it was $60 for the gutter mounts from JCR.

I need opinions/ideas before I put the money into it. I want it to be very strong and I'm not sure if the 11 gauge is going to be tough enough.

thanks

I need opinions/ideas before I put the money into it. I want it to be very strong and I'm not sure if the 11 gauge is going to be tough enough.

thanks