cherokee89

NAXJA Forum User

- Location

- St. Louis, MO

Hello All,

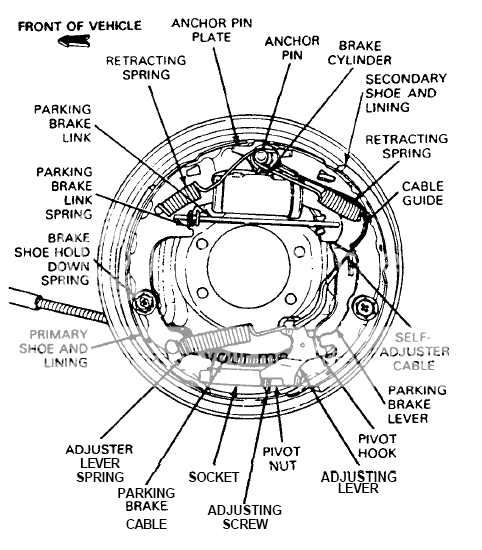

I am seeking some assistance with my rear brakes. I recently installed new drums, shoes, hardware and cylinders. I measured the new drums against the old ones and they seemed to be the correct size. My problem is, in order to get the drums on, I have to have the star-adjuster really loose. Like, rattle around loose. I adjust it in, slide the drums on, and tighten the star until the shoes basically drag. Tighter than it should be, the adjuster lever, shoe spring, and adjuster cable eventually fall out of place and come disconnected. Naturally, this makes a nasty noise and I have to take the drum off to fix it. I have tried everything from the parking brake being so loose that it does not work, to so tight that I cannot drive the Jeep. I am starting to think I was sold the wrong brake shoes. Just so we are all clear on the parts I referred to, I typed them exactly as shown in the diagram on this fine page: http://www.lunghd.com/Tech_Articles/Suspension_Steering_Axles_and_Brakes/Drum_Brake_Service.htm

Any thoughts on what I should try? When the parking brake was too loose, I was able to drive it for a while with no problems, but the adjuster lever eventually fell out of place. I appreciate any assistance. I will say there is the possibility that I am a bonehead, but I don't think I have anything wrong with the install. And, before anyone asks, yes the shoes are on correctly.

Edit:1989 XJ Ltd, 4.0, AW4, NP242

I am seeking some assistance with my rear brakes. I recently installed new drums, shoes, hardware and cylinders. I measured the new drums against the old ones and they seemed to be the correct size. My problem is, in order to get the drums on, I have to have the star-adjuster really loose. Like, rattle around loose. I adjust it in, slide the drums on, and tighten the star until the shoes basically drag. Tighter than it should be, the adjuster lever, shoe spring, and adjuster cable eventually fall out of place and come disconnected. Naturally, this makes a nasty noise and I have to take the drum off to fix it. I have tried everything from the parking brake being so loose that it does not work, to so tight that I cannot drive the Jeep. I am starting to think I was sold the wrong brake shoes. Just so we are all clear on the parts I referred to, I typed them exactly as shown in the diagram on this fine page: http://www.lunghd.com/Tech_Articles/Suspension_Steering_Axles_and_Brakes/Drum_Brake_Service.htm

Any thoughts on what I should try? When the parking brake was too loose, I was able to drive it for a while with no problems, but the adjuster lever eventually fell out of place. I appreciate any assistance. I will say there is the possibility that I am a bonehead, but I don't think I have anything wrong with the install. And, before anyone asks, yes the shoes are on correctly.

Edit:1989 XJ Ltd, 4.0, AW4, NP242

Last edited: