AT FAB XJ

NAXJA Forum User

- Location

- Frisco Texas

Anyone else think the old Shistler/Jeep XJ OEM cooling design may be a tad bit inadequate? If you live and drive in the deep south you do!!!!

The main clutched mechanical fan is small and offset to one side of the radiator and the electric AUX fan is only activated if the AC is on or the temp reaches 220*F. It will turn off when it reaches 200* again. This makes them sit at 220F* in the summer and have issues with heat soaking the fuel in the injectors and lock them up between a 15-30 min. sit after running at operating temp.

Earlier this year I decided to give the cooling system design the benefit of my doubt and I replaced everything with quality OEM style parts including the radiator with a very high end all metal brass high flow, new water pump, fan clutch, 180* Tstat, Tstat housing, flushed and replaced all fluid

After all this the system did not change its behavior. It does run great and cool at highway speeds regardless of ambient temp but when you come to a stoplight or pull into a parking lot it runs very hot. over 220*.

It is not overheating but sits around 220*. If you you let it sit for a good 5 minutes it will eventually start to cool down to around 210*. If you shut it down at 220* it will be at almost 235* when you restart it within 10 minutes.

It has not overheated or boiled over at all but it has caused a few pinhole leaks after a few months in the tstat and water pump housings that are driving me nuts. I have re-RTVd both several times this year and it is wearing me out walking by my XJ and smelling coolant every few months.

All of what I described is considered normal operating temps and ranges for an XJ according to Jeep, Alldata, and every other tech resource available.

Every XJ we have worked on in our shop has acted the same way regardless of age or condition.....

With the lift, tires, and armor I recently added, this situation has not been improved so after months of research I finally decided to upgrade.

A lot of people go with a ZJ fan clutch that will give you more mechanical fan output when hot at low RPMs. The problem with this is the fan is at a much higher lockup rate and will make the engine use more fuel at highway speeds. I didn't want to go this route. Others tend to go cheap an throw some hood vents in it and call it a day. Where this would probably alleviate most of my problem, I am just not a fan of rain and snow falling directly into my hood.

The 4.0 in the XJ easily needs 2500-3000 CFM similar to a smallblock V8 like a GM 350. The stock 15" fan pulls around 700 CFM at idle and approx 2000 CFM at 2500 RPMS. The stock electric fan pulls about 800 CFM. This is not enough to keep this coolant system down at or below 210 on a regular basis with the 100*F+ temps we get down here in Texas.

After a lot of research due to the unavailability of a good "kit", I decided to replace both fans with a dual electric 13" fan setup from Derale with a DIF variable speed fan controller. The fans are a puller setup and will pull 4000CFM at 25 amps per fan. This is a lot of amperage and draw on the batter system so I didn't just want an on/off type typical temp switch. Instead I went wanted to go with a variable speed controller. I was only able to find 2 good adjustable fan controllers, a flex-a-lite and a DIF. Unfortunately the cheaper flex-a-lite can't handle more than 45amps which I called to confirm with flex a lite. I then ordered a DIF variable speed fan controller which can handle up to 60 amps. I am going to program the DIF to turn the fans on at about 185-190* and try to keep my temps below 200* at all times.

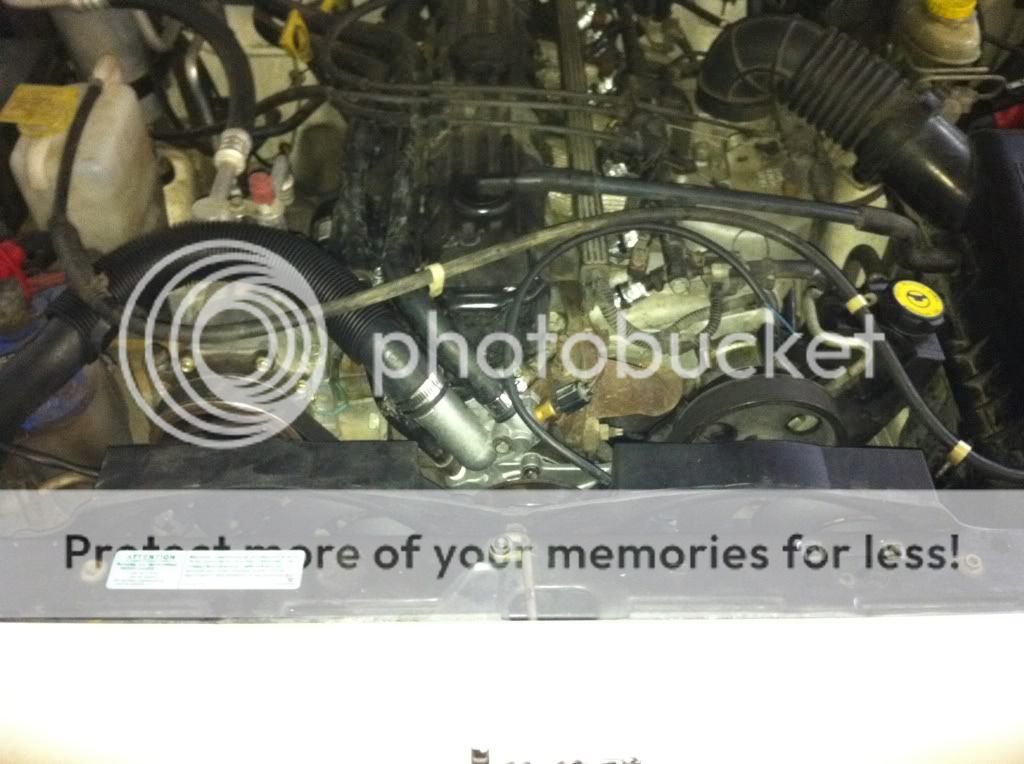

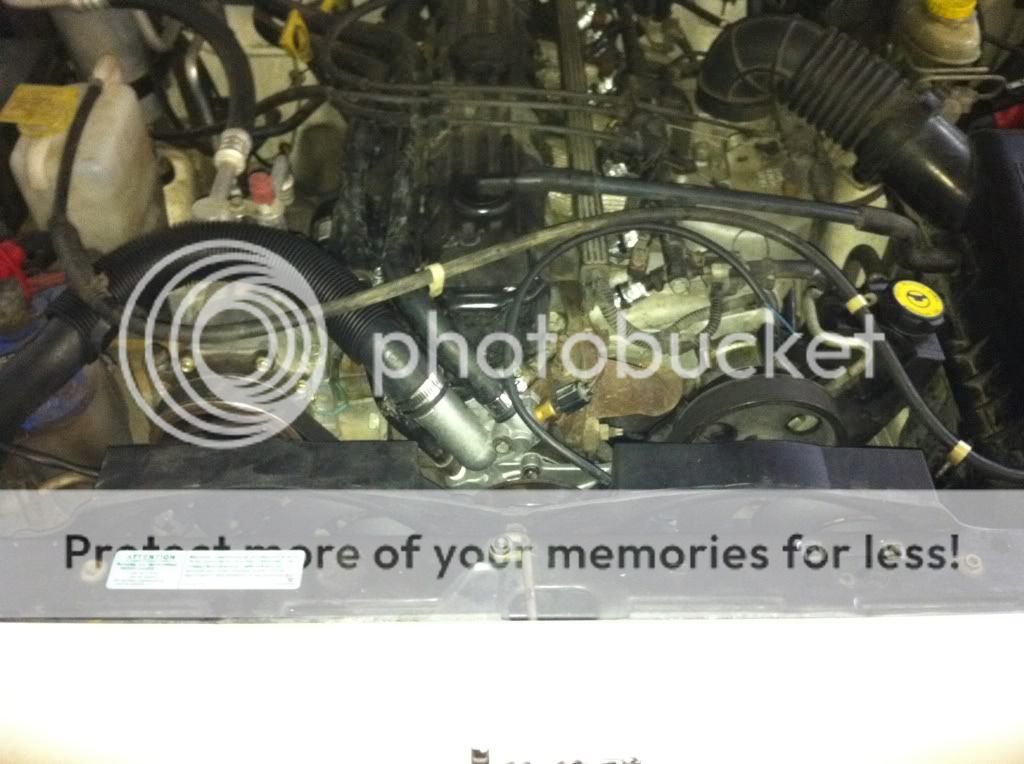

I also ordered a FlowKooler high flow water pump that doubles the water flow at idle and a Robert Shaw high flow thermostat. After replacing the hoses, pump, and tstat I started modifying the fans to get them to fit in the 12" tall 30" wide space behind the radiator. The Derale kit is the smallest setup I could find with enough CFM to cool the engine. It is approx 28" wide and about 14.5' tall. It is also 3.25" deep which needed to be trimmed as well. Fortunately the ABS plastic the fans are made out of is strong so even after removing this much material they weren't flimsy. I pretty much cut all the extra plastic I could to get them to set inward towards the radiator, away from the pulleys as much as possible, and low enough to clear the hood line.

I am not finished yet. I still need to cut out some HD rubber to put on top of the fans and bolt down under the top of the radiator to cover the gap on top. The fans clear the hood and are bolted to the backside of the radiator brace on top and bottom so they won't move at all. I will get the wiring done shortly and post up the final pics and the mess of wiring and programming required with the DIF controller.

Here are some pics of the progress and the album:http://s127.photobucket.com/albums/p145/06unlimitedrubi/XJ Ultimate Cooling/

The main clutched mechanical fan is small and offset to one side of the radiator and the electric AUX fan is only activated if the AC is on or the temp reaches 220*F. It will turn off when it reaches 200* again. This makes them sit at 220F* in the summer and have issues with heat soaking the fuel in the injectors and lock them up between a 15-30 min. sit after running at operating temp.

Earlier this year I decided to give the cooling system design the benefit of my doubt and I replaced everything with quality OEM style parts including the radiator with a very high end all metal brass high flow, new water pump, fan clutch, 180* Tstat, Tstat housing, flushed and replaced all fluid

After all this the system did not change its behavior. It does run great and cool at highway speeds regardless of ambient temp but when you come to a stoplight or pull into a parking lot it runs very hot. over 220*.

It is not overheating but sits around 220*. If you you let it sit for a good 5 minutes it will eventually start to cool down to around 210*. If you shut it down at 220* it will be at almost 235* when you restart it within 10 minutes.

It has not overheated or boiled over at all but it has caused a few pinhole leaks after a few months in the tstat and water pump housings that are driving me nuts. I have re-RTVd both several times this year and it is wearing me out walking by my XJ and smelling coolant every few months.

All of what I described is considered normal operating temps and ranges for an XJ according to Jeep, Alldata, and every other tech resource available.

Every XJ we have worked on in our shop has acted the same way regardless of age or condition.....

With the lift, tires, and armor I recently added, this situation has not been improved so after months of research I finally decided to upgrade.

A lot of people go with a ZJ fan clutch that will give you more mechanical fan output when hot at low RPMs. The problem with this is the fan is at a much higher lockup rate and will make the engine use more fuel at highway speeds. I didn't want to go this route. Others tend to go cheap an throw some hood vents in it and call it a day. Where this would probably alleviate most of my problem, I am just not a fan of rain and snow falling directly into my hood.

The 4.0 in the XJ easily needs 2500-3000 CFM similar to a smallblock V8 like a GM 350. The stock 15" fan pulls around 700 CFM at idle and approx 2000 CFM at 2500 RPMS. The stock electric fan pulls about 800 CFM. This is not enough to keep this coolant system down at or below 210 on a regular basis with the 100*F+ temps we get down here in Texas.

After a lot of research due to the unavailability of a good "kit", I decided to replace both fans with a dual electric 13" fan setup from Derale with a DIF variable speed fan controller. The fans are a puller setup and will pull 4000CFM at 25 amps per fan. This is a lot of amperage and draw on the batter system so I didn't just want an on/off type typical temp switch. Instead I went wanted to go with a variable speed controller. I was only able to find 2 good adjustable fan controllers, a flex-a-lite and a DIF. Unfortunately the cheaper flex-a-lite can't handle more than 45amps which I called to confirm with flex a lite. I then ordered a DIF variable speed fan controller which can handle up to 60 amps. I am going to program the DIF to turn the fans on at about 185-190* and try to keep my temps below 200* at all times.

I also ordered a FlowKooler high flow water pump that doubles the water flow at idle and a Robert Shaw high flow thermostat. After replacing the hoses, pump, and tstat I started modifying the fans to get them to fit in the 12" tall 30" wide space behind the radiator. The Derale kit is the smallest setup I could find with enough CFM to cool the engine. It is approx 28" wide and about 14.5' tall. It is also 3.25" deep which needed to be trimmed as well. Fortunately the ABS plastic the fans are made out of is strong so even after removing this much material they weren't flimsy. I pretty much cut all the extra plastic I could to get them to set inward towards the radiator, away from the pulleys as much as possible, and low enough to clear the hood line.

I am not finished yet. I still need to cut out some HD rubber to put on top of the fans and bolt down under the top of the radiator to cover the gap on top. The fans clear the hood and are bolted to the backside of the radiator brace on top and bottom so they won't move at all. I will get the wiring done shortly and post up the final pics and the mess of wiring and programming required with the DIF controller.

Here are some pics of the progress and the album:http://s127.photobucket.com/albums/p145/06unlimitedrubi/XJ Ultimate Cooling/

Last edited: