It's a common problem we all have high powered accessories that we like to have on the battery post.

Alarms,KC's,Winches,amps,E-fans (I have 4!), MSD ignitions and so on with some or all of these things our battery post starts looking like a bowl of spaghetti.

How many connectors have you broken or disconnected when tightening down your terminals?

What is your solution for this mess? I saw a post while back that had a thin thing with a bunch of connectors at the base of the battery post. Kinda cool but a little too thin for my taste.

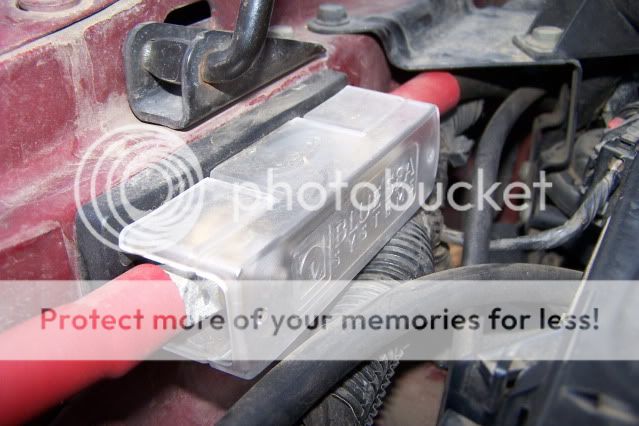

This is not mine, I pulled it from JF. could be worse

Alarms,KC's,Winches,amps,E-fans (I have 4!), MSD ignitions and so on with some or all of these things our battery post starts looking like a bowl of spaghetti.

How many connectors have you broken or disconnected when tightening down your terminals?

What is your solution for this mess? I saw a post while back that had a thin thing with a bunch of connectors at the base of the battery post. Kinda cool but a little too thin for my taste.

This is not mine, I pulled it from JF. could be worse