northwestxj

NAXJA Member #1283

- Location

- washington

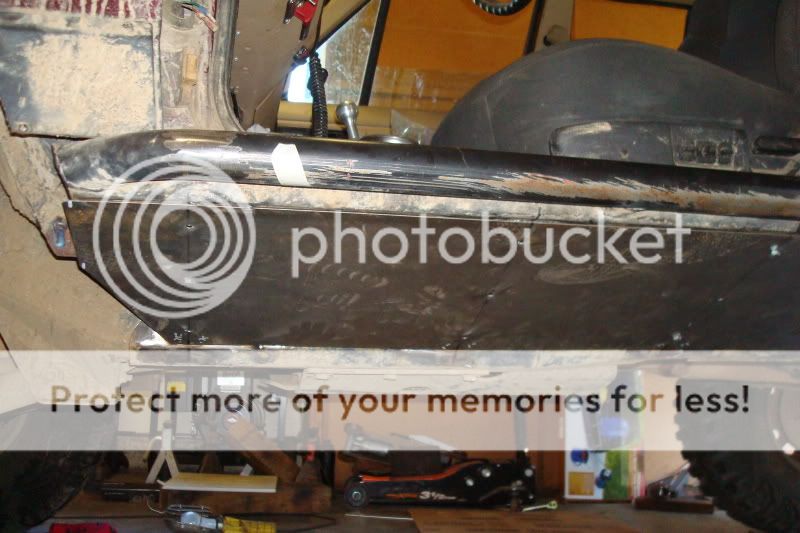

Started a project on my XJ about a week ago. Previously I had the standard cut out your rockers, replace with 2x4 rec. tube. After bending up the passenger side really bad a couple years ago, I had three triangular supports welded onto the reinforced frame. This worked for quite a while, but they slowly have both been bending up again. Because I don't run a whole lot of lift, I hit them quite a bit, and after smacking the drivers side real good recently and bending it up it was time to do something else.

I decided to cut them out and move them up 2" to the door sill. Then I am running 5 legs down to the frame on each side as tie-ins. To do this and keep clearance, I had to cut into the floor. The tie-ins will get a thin steel plate over them, and then a layer of UHMW, but I'm not that far yet. Onto some pictures...

The back ones will get tied into the leaf spring hanger as well.

Three of the tie-ins on each side are 1.5"x2" 1/8 wall, and the two in the second and fourth spot are 2"x2" 3/16 wall.

This is where I'm at right now. Still need to do most all the welding, cut ~2" off the bottom of my doors, reassemble interior, fenders, etc.

I decided to cut them out and move them up 2" to the door sill. Then I am running 5 legs down to the frame on each side as tie-ins. To do this and keep clearance, I had to cut into the floor. The tie-ins will get a thin steel plate over them, and then a layer of UHMW, but I'm not that far yet. Onto some pictures...

The back ones will get tied into the leaf spring hanger as well.

Three of the tie-ins on each side are 1.5"x2" 1/8 wall, and the two in the second and fourth spot are 2"x2" 3/16 wall.

This is where I'm at right now. Still need to do most all the welding, cut ~2" off the bottom of my doors, reassemble interior, fenders, etc.