XJCreeper

NAXJA Forum User

- Location

- Castro Valley, California

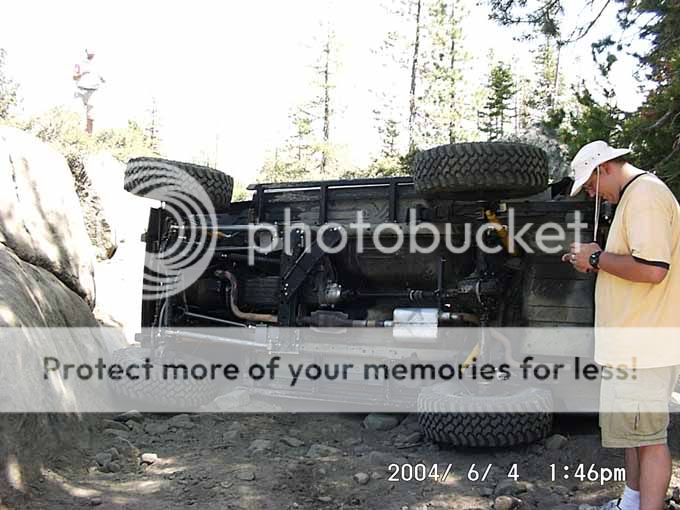

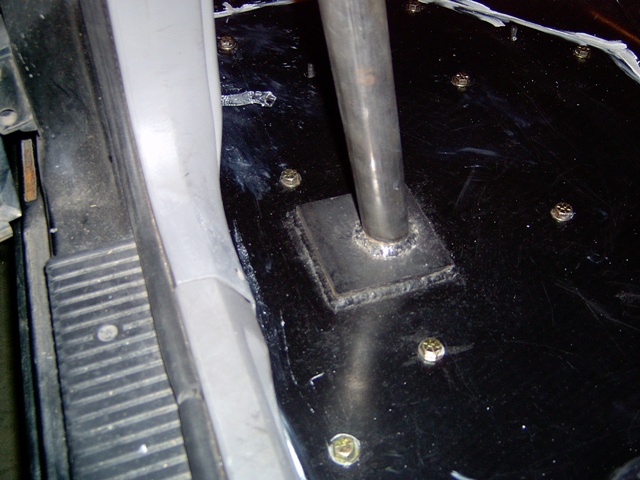

I got my D&C cage installed and noticed something odd. When riding down a bumpy freeway and driving at a certain speed I noticed that the roll cage will move and ocilate opposite the body motion. To attach it I plated the floor with 1/8" sheet steel. The foot plates were then welded to the 1/8" plated floor. Here some pic's on the install.

To solve the problem I bought some more tube and I'm going to add some triangulation throughout the cage. However, I was also thinking that tying the cage into various points on the unibody frame would help as well.

Has anyone done this before and where are the best tie-in points are on the XJ unibody. Someone I talked with and respect suggested that tying in the cage that is currently attached to the floor only would put additional stresses on the rest of the unibody if I tied it into the roof. Please let me know your thoughts and experiences on doing this. I'd greatly appreciate the forums input.

I really like it D&C cage with one exception. It would be nice if the bar above the windshield contoured the top of the winshield frame closer. IMHO it would protect the front roof better and move it farther from the noggin'. If I hit the lotto and can buy a bender I'd do it. In the meantime it's heads up on the trail!

To solve the problem I bought some more tube and I'm going to add some triangulation throughout the cage. However, I was also thinking that tying the cage into various points on the unibody frame would help as well.

Has anyone done this before and where are the best tie-in points are on the XJ unibody. Someone I talked with and respect suggested that tying in the cage that is currently attached to the floor only would put additional stresses on the rest of the unibody if I tied it into the roof. Please let me know your thoughts and experiences on doing this. I'd greatly appreciate the forums input.

I really like it D&C cage with one exception. It would be nice if the bar above the windshield contoured the top of the winshield frame closer. IMHO it would protect the front roof better and move it farther from the noggin'. If I hit the lotto and can buy a bender I'd do it. In the meantime it's heads up on the trail!

Last edited by a moderator: