- Location

- Lafayette, CA

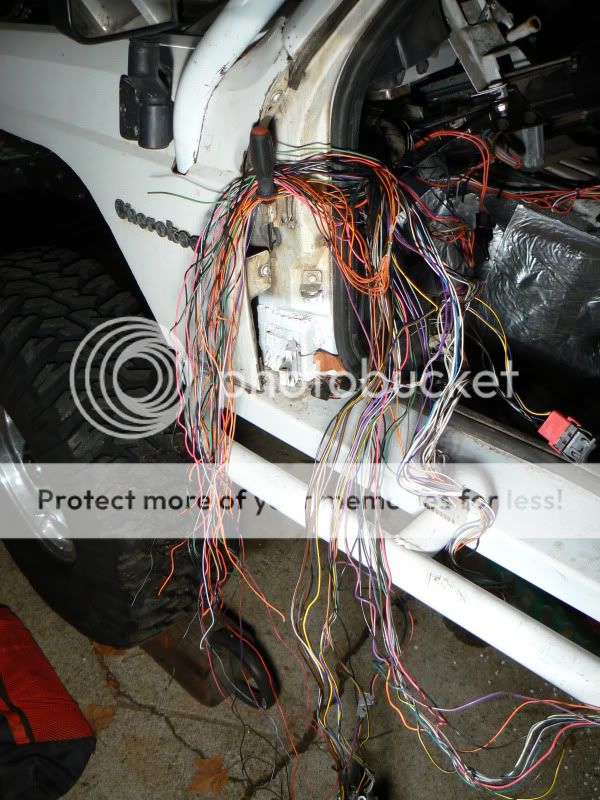

Another one of my projects. Removed my dash, removed the AC and heater and am in the process of cleaning up the stock wiring harness. Ive found I no longer need almost half of the wire going behind the dash which is awesome, but now I am not sure how to cap the wires since I am unable to get them out of the fuse block.

All the wires on the left I no longer need, the right most are either for the CD player or for the instrument panel. Of course the CD player doesnt work, but thats a whole other issue

So Im going to cut all those wires down, but how do I cap them all? Fold each wire over and wrap it with electrical tape?

Thanks

All the wires on the left I no longer need, the right most are either for the CD player or for the instrument panel. Of course the CD player doesnt work, but thats a whole other issue

So Im going to cut all those wires down, but how do I cap them all? Fold each wire over and wrap it with electrical tape?

Thanks