winkosmosis

NAXJA Forum User

- Location

- Maui, Hawaii

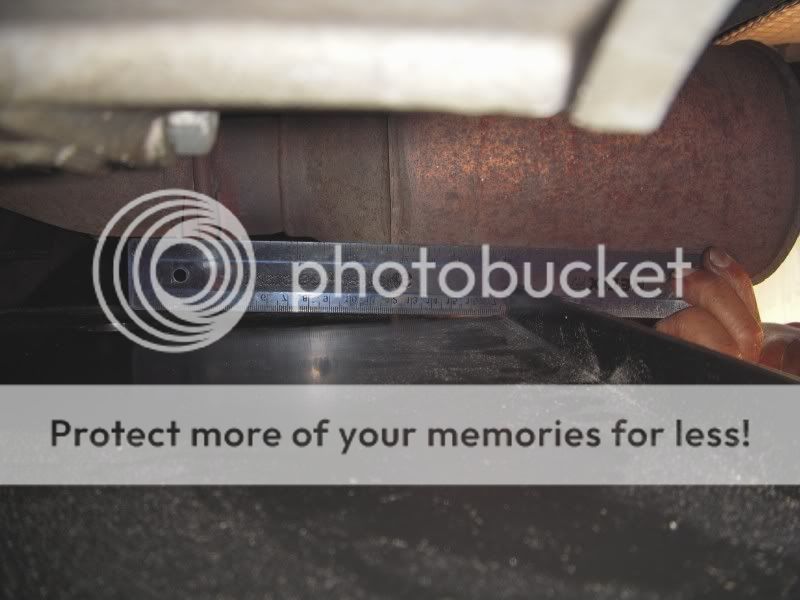

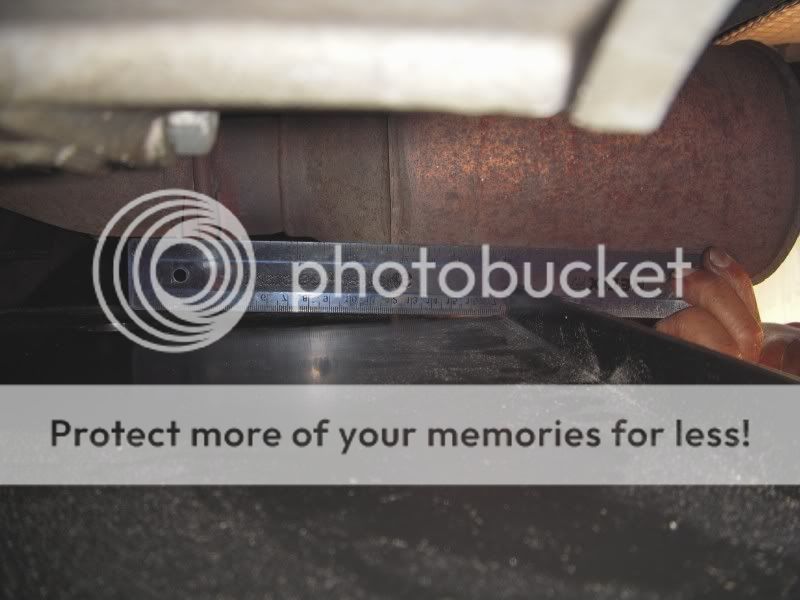

According to Dirk at DPG Offroad, most round cats fit fine with the belly skid, but a few need the cat relocated by a muffler shop. I have the bad luck of a non fitting cat.

But the big problem is that there seems to be no way to move it enough. The segment of pipe between the cat and the muffler contains the O2 sensor, so only about 2" can be cut to move the cat rearward. The muffler can't really be moved back because it will conflict with the pinion.

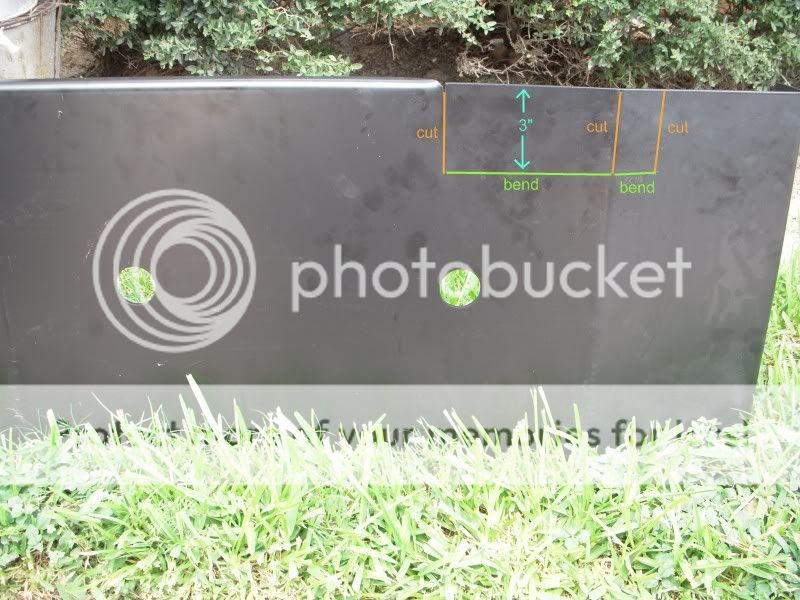

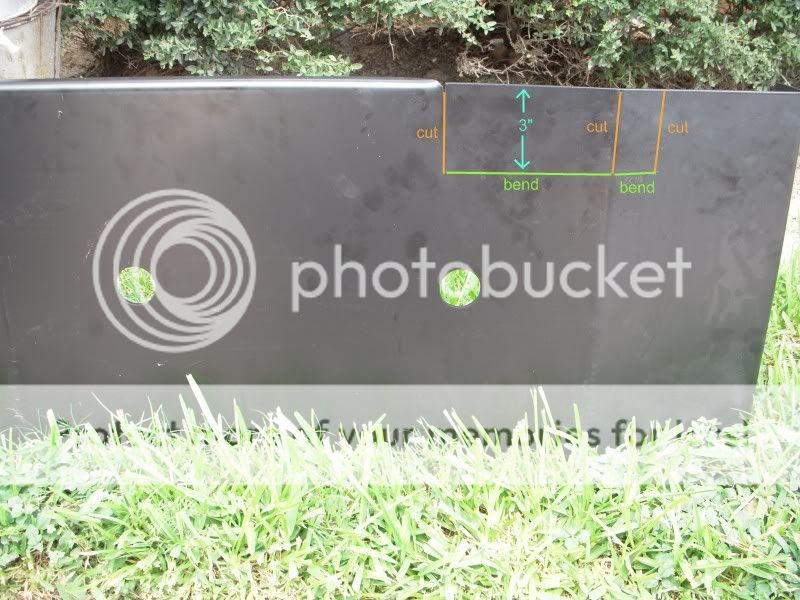

How about cutting the skid and bending the pieces downward to clear the cat and also provide some protection? Is that doable with the 3/16 steel? My dad thinks bending will be possible by cutting a groove into the steel but I'm skeptical.

Could also replace the cat with a flatter one

But the big problem is that there seems to be no way to move it enough. The segment of pipe between the cat and the muffler contains the O2 sensor, so only about 2" can be cut to move the cat rearward. The muffler can't really be moved back because it will conflict with the pinion.

How about cutting the skid and bending the pieces downward to clear the cat and also provide some protection? Is that doable with the 3/16 steel? My dad thinks bending will be possible by cutting a groove into the steel but I'm skeptical.

Could also replace the cat with a flatter one

Last edited: